Space Shuttle System and Mission Profile

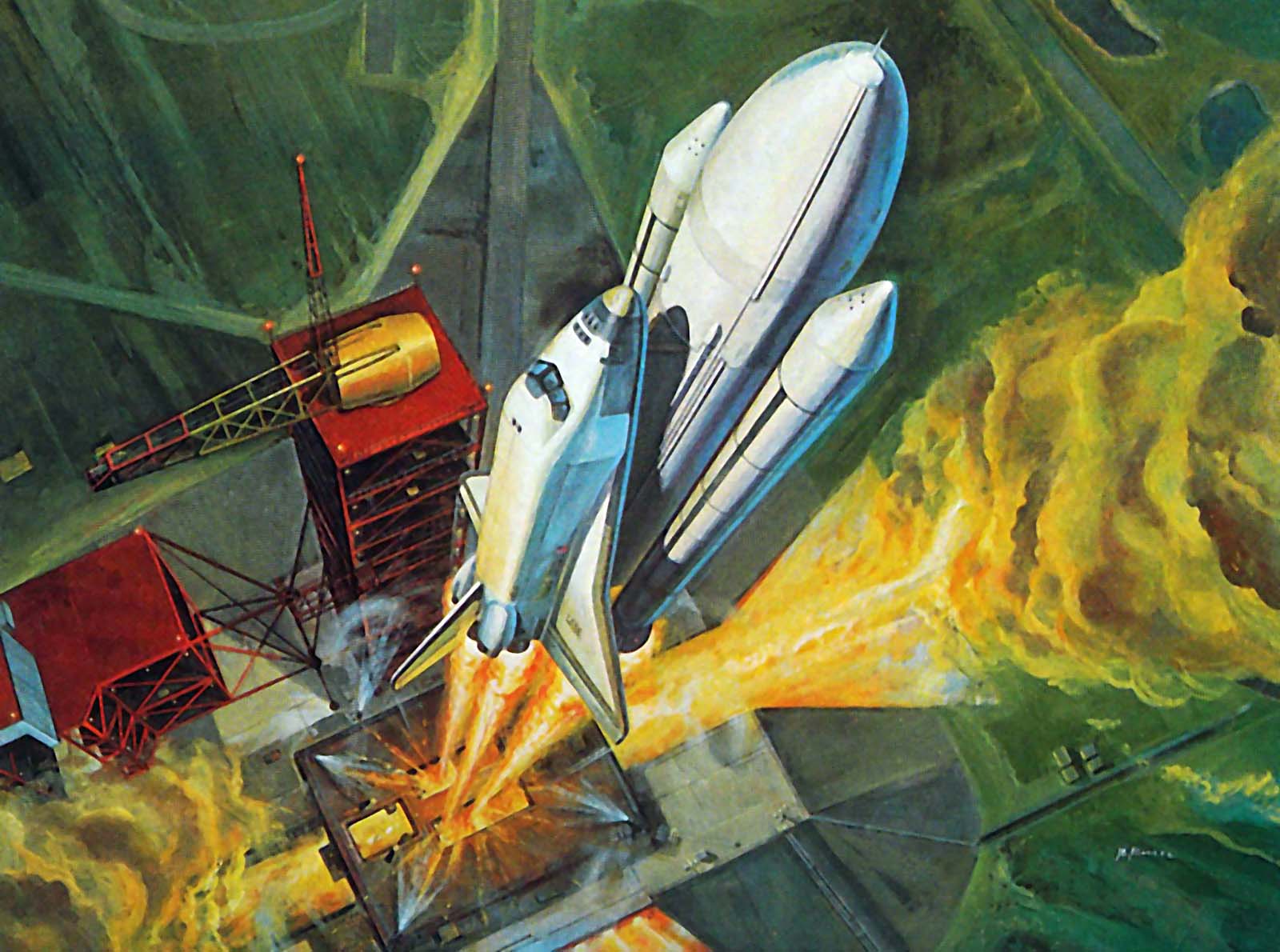

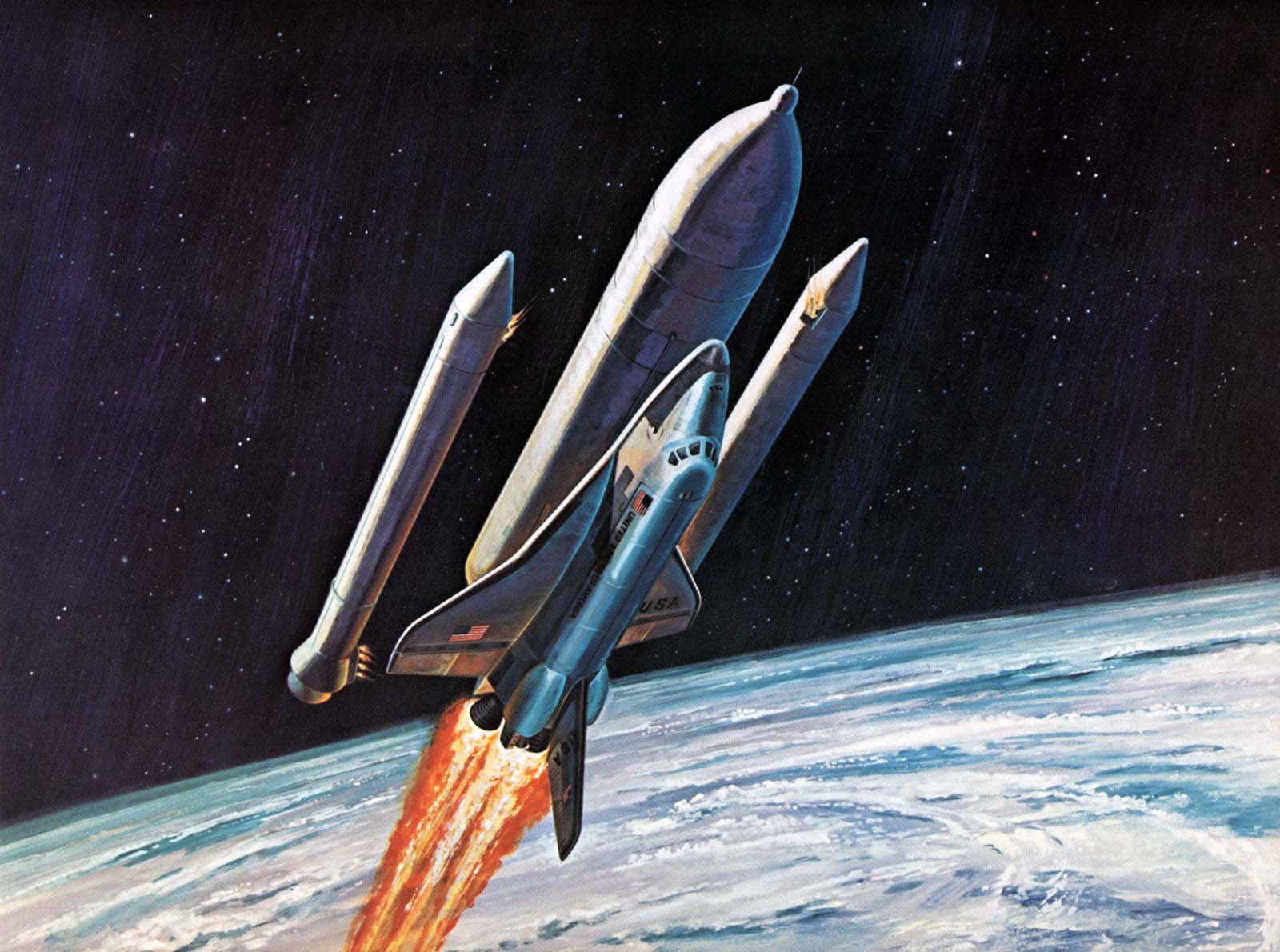

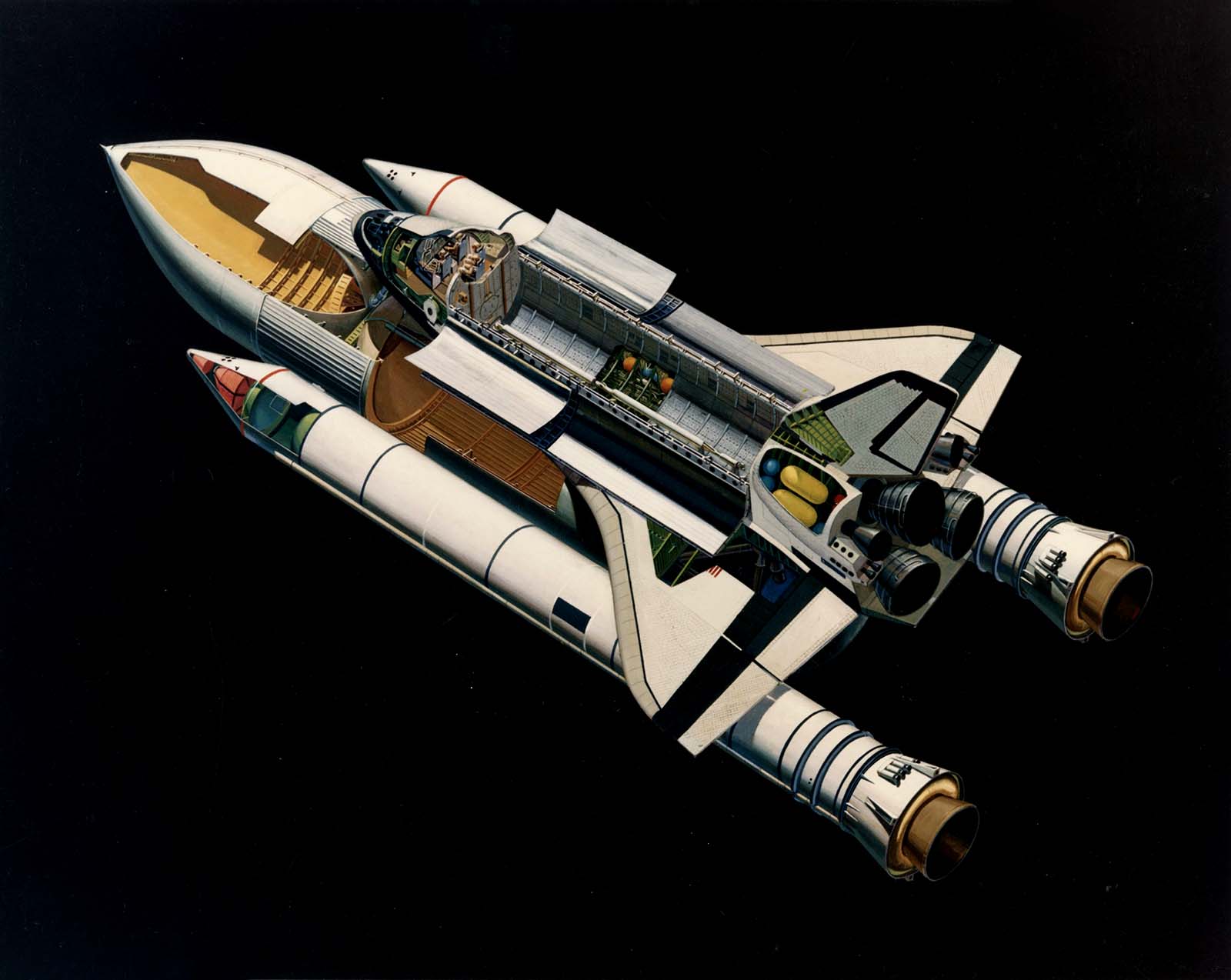

The Space Shuttle flight system is composed of the Orbiter, an external tank (ET) that contains the ascent propellant to be used by the Orbiter main engines, and two solid rocket boosters (SRB’s). The Orbiter and SRB’s are reusable; the external tank is expended on each launch.

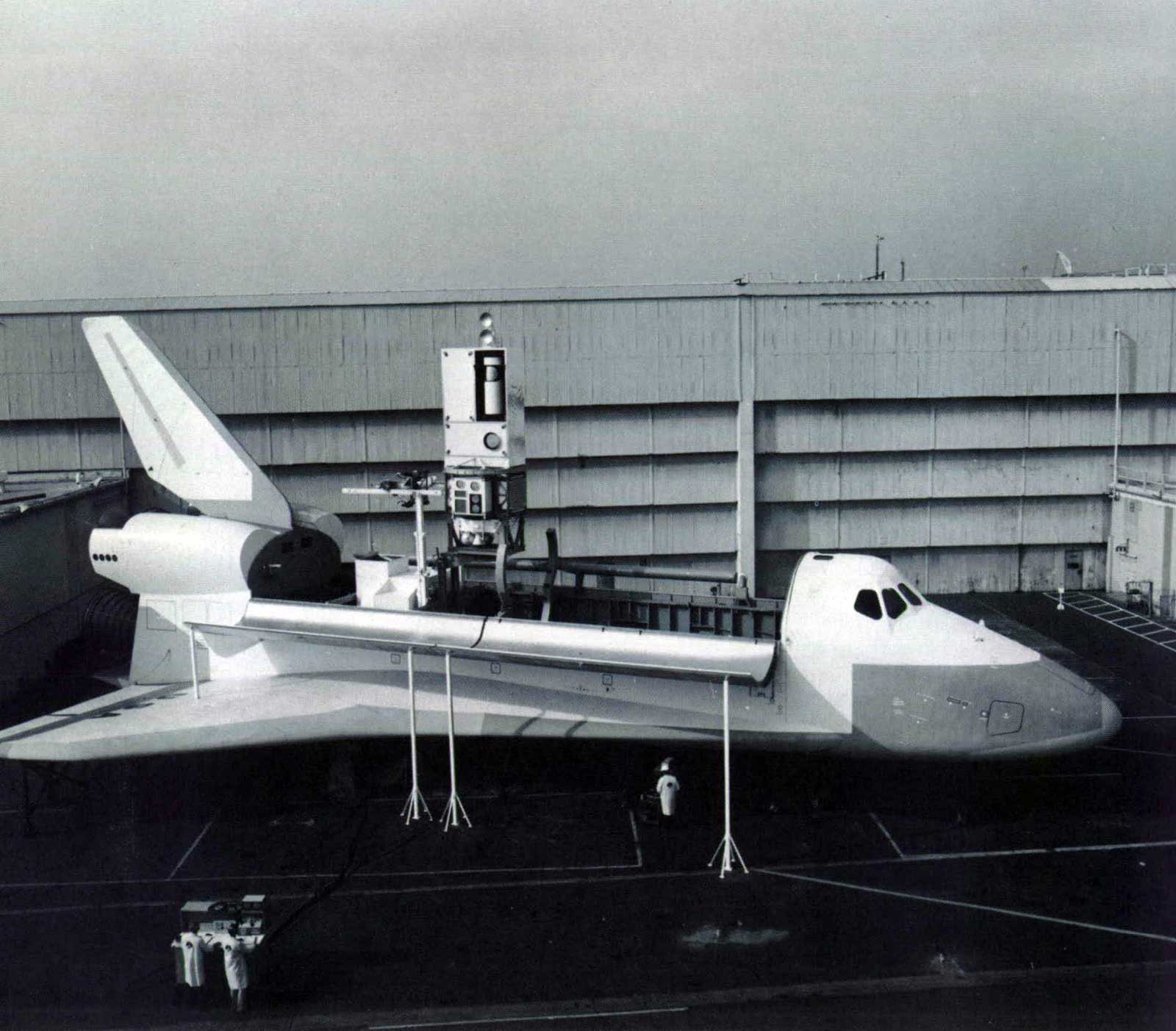

The Space Shuttle mission begins with the installation of the mission payload into the Orbiter payload bay. The payload will be checked and serviced before installation and will be activated on orbit. Flight safety items for some payloads will be monitored by a caution and warning system.

The SRB’s and the Orbiter main engine will fire in parallel at lift-off. The two SRB’s are jettisoned after burnout and are recovered by means of a parachute system. The large external tank is jettisoned before the Space Shuttle Orbiter goes into orbit. The orbital maneuvering system (OMS) of the Orbiter is used to attain the desired orbit and to make any subsequent maneuvers that may be required during the mission. When the payload bay doors in the top of the Orbiter fuselage open to expose the payload, the crewmen are ready to begin payload operations.

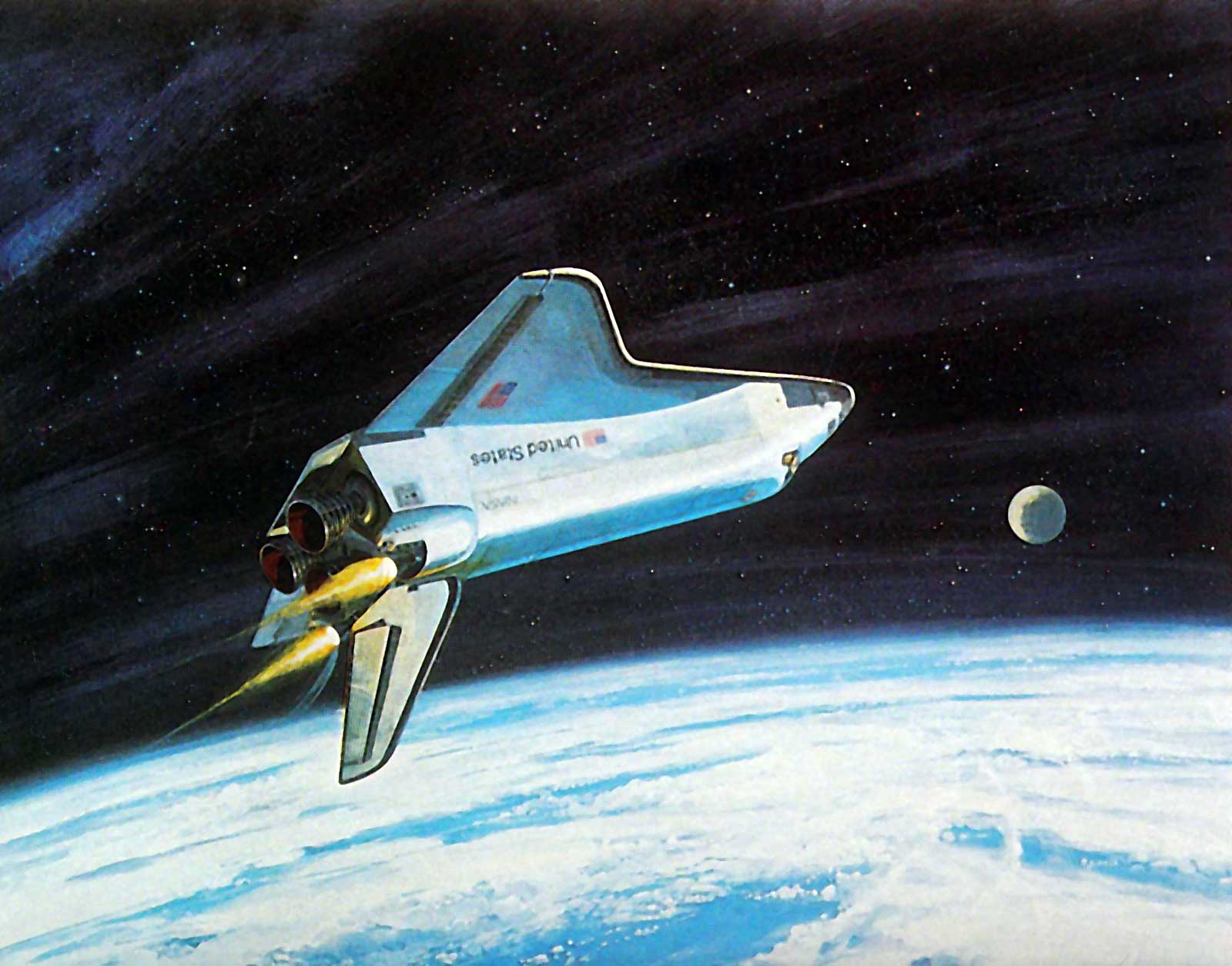

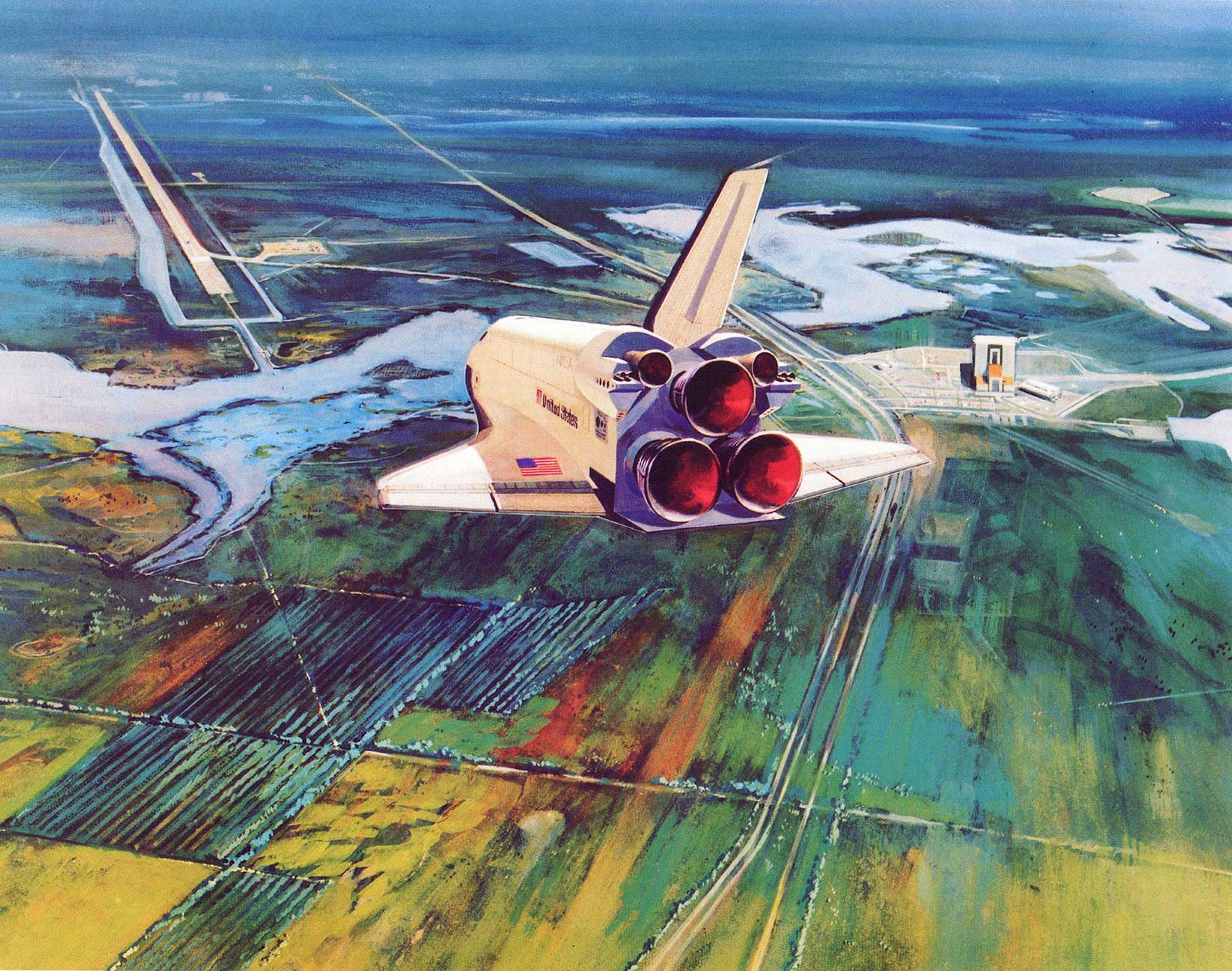

After the orbital operations, deorbiting maneuvers are initiated. Reentry is made into the Earths atmosphere at a high angle of attack At low altitude, the Orbiter goes into horizontal flight for an aircraft-type approach and landing A 2-week ground turnaround is the goal for reuse of the Space Shuttle Orbiter.

The nominal duration of the missions is 7 days. The mission duration can be extended to as long as 30 days if the necessary consumables are added.

Height: 45.6 km (24.6 n mi)

Velocity: 1391 m/sec (2704 kn)

Height: 277.8 km (150 n mi) - typical

Veiocity: 7847 m/sec (15,254 kn)

Height: 185 to 1110 km (100 to 600 n mi)

Duration: Up to 30 days

Height: 1219 km (76 n mi)

Velocity: 7434 m/sec (14,451 kn)

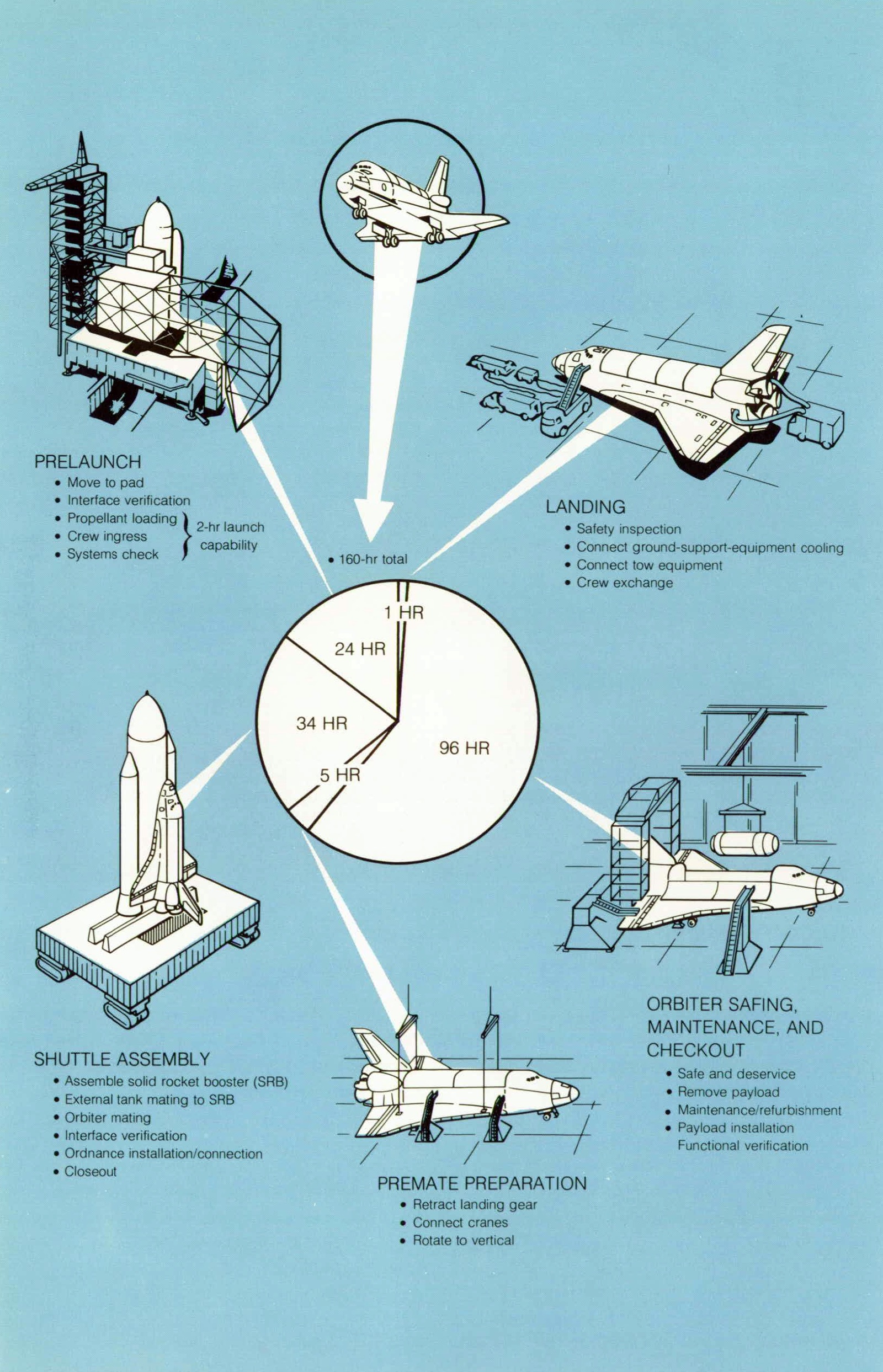

GROUND TURNAROUND

The Space Shuttle Orbiter is designed for a 2-week ground turnaround, from landing to relaunch. About 160 hours of actual work will be required.

As soon as the Orbiter returns from space, it must undergo safing before payloads can be removed and maintenance and refurbishment begun. Safing operations include draining and purging of the propellant feedlines and removal of explosive actuators.

Next, the payload-bay support equipment must be inspected and serviced. New payloads will be installed. The thermal protection system, landing gear system, main and auxiliary propulsion systems, power units, flight instrumentation, and communications systems must also be inspected and, if necessary, repaired.

These functions will take approximately two-thirds of the total processing time before relaunch. From there, the Orbiter will be towed to the assembly building, where it will be lifted to vertical and mated to the solid rocket boosters and external tank, already in place on the mobile launcher platform.

The integrated Space Shuttle will then be moved to the launch pad for another trip into space.

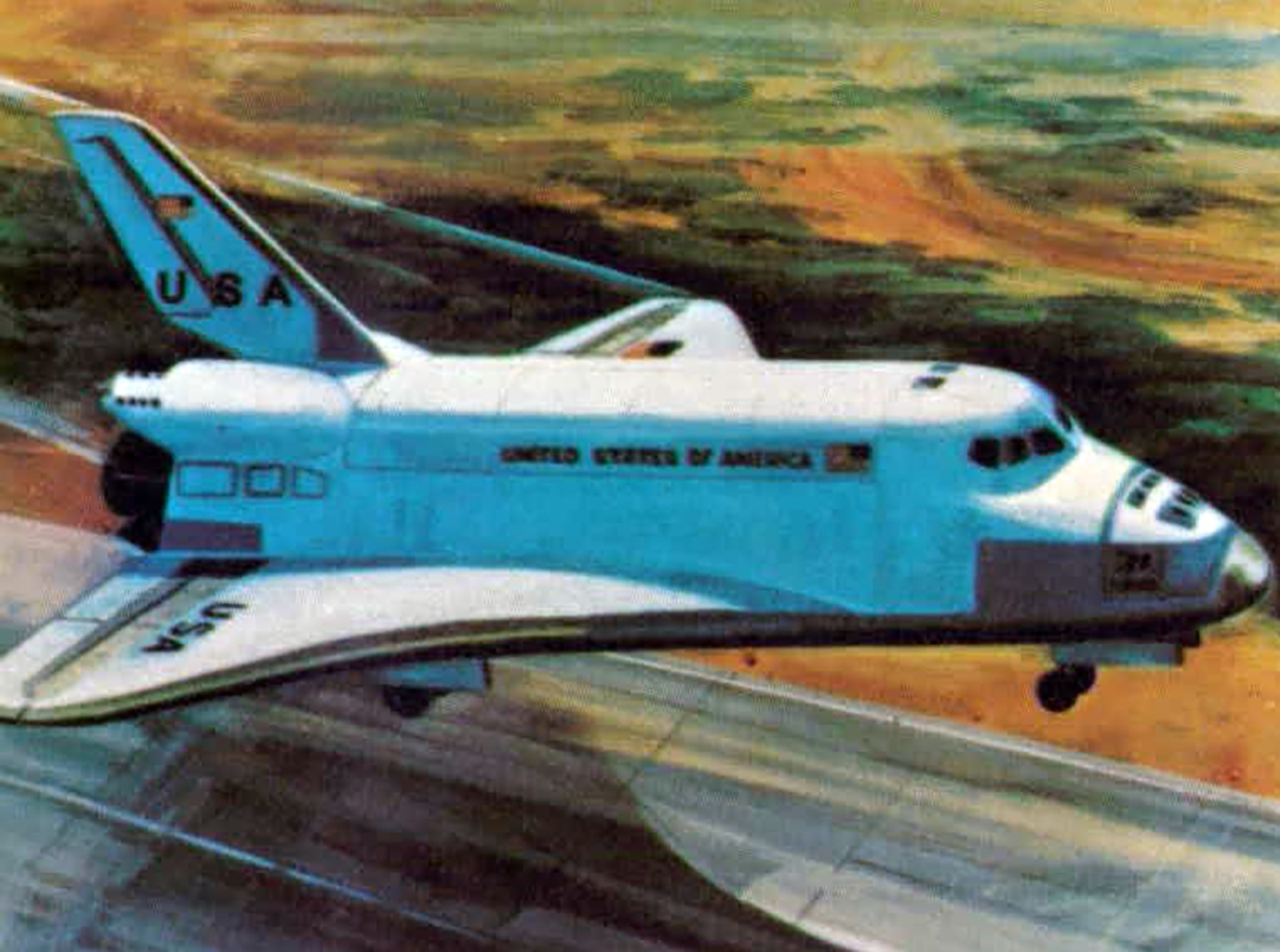

SPACE SHUTTLE VEHICLE

The Orbiter is designed to carry into orbit a crew of up to seven, including scientific and technical personnel, and the payloads. The rest of the Shuttle system (SRB’s and external fuel tank) is required to boost the Orbiter into space. The smaller Orbiter rocket engines of the orbital maneuvering system (OMS) provide maneuvering and control during space flight; during atmospheric flight the Orbiter is controlled by the aerodynamic surfaces on the wings and by the vertical stabilizer.

On a standard mission, the Orbiter can remain in orbit for 7 days, return to Earth with personnel and payload, land like an airplane, and be readied for another flight in 14 days. The Shuttle can be readied for a rescue mission launch from standby status within 24 hours after notification. For emergency rescue, the cabin can accommodate as many as 10 persons; thus, all occupants of a disabled Orbiter could be rescued by another Shuttle.

The SRB’s, which burn in parallel with the Orbiter main propulsion system, are separated from the Orbiter/external tank at an altitude of approximately 45 kilometers (24 nautical miles), descend on parachutes, and land in the ocean approximately 278 kilometers (150 nautical miles) from the launch site. They are recovered by ships, returned to land, refurbished, and then reused.

After SRB separation, the Orbiter main propulsion system continues to burn until the Orbiter achieves a velocity just short of orbital requirements. The external tank then separates and falls into a remote area of the Indian or the South Pacific Ocean, depending on the launch site and mission. The OMS completes insertion of the Orbiter into the desired orbit.

CREW AND PASSENGER ACCOMMODATIONS

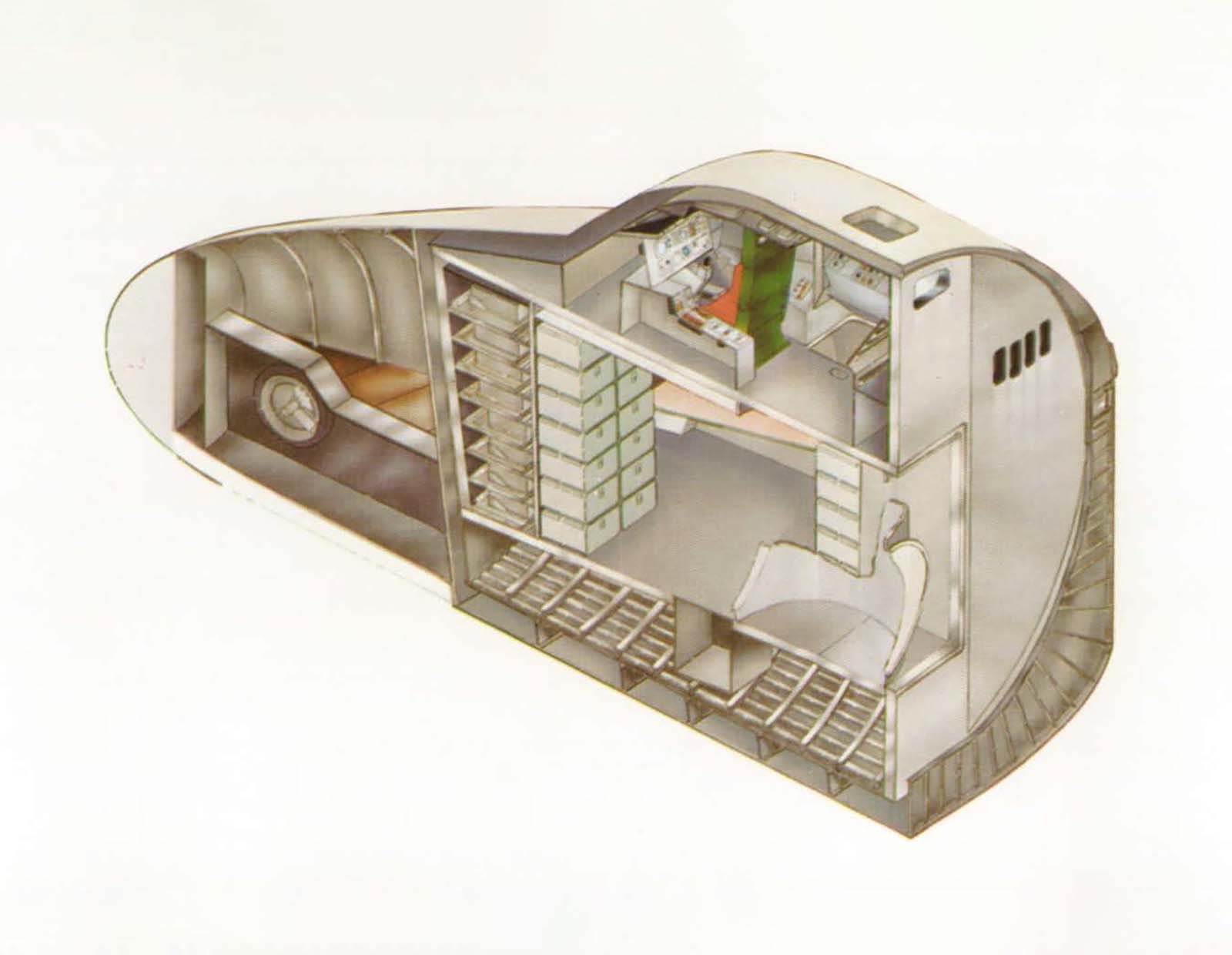

The crew and passengers occupy a two-level cabin at the forward end of the Orbiter. The crew controls the launch, orbital maneuvering, atmospheric entry, and landing phases of the mission from the upper level flight deck Payload handling is accomplished by crewmen at the aft cabin payload station.

Seating for passengers and a living area are provided on the lower deck. The cabin will have a maximum of utility; mission flexibility is achieved with a minimum of volume, complexity, and weight. Space flight will no longer be limited to intensively trained, physically perfect astronauts but will now accommodate experienced scientists and technicians.

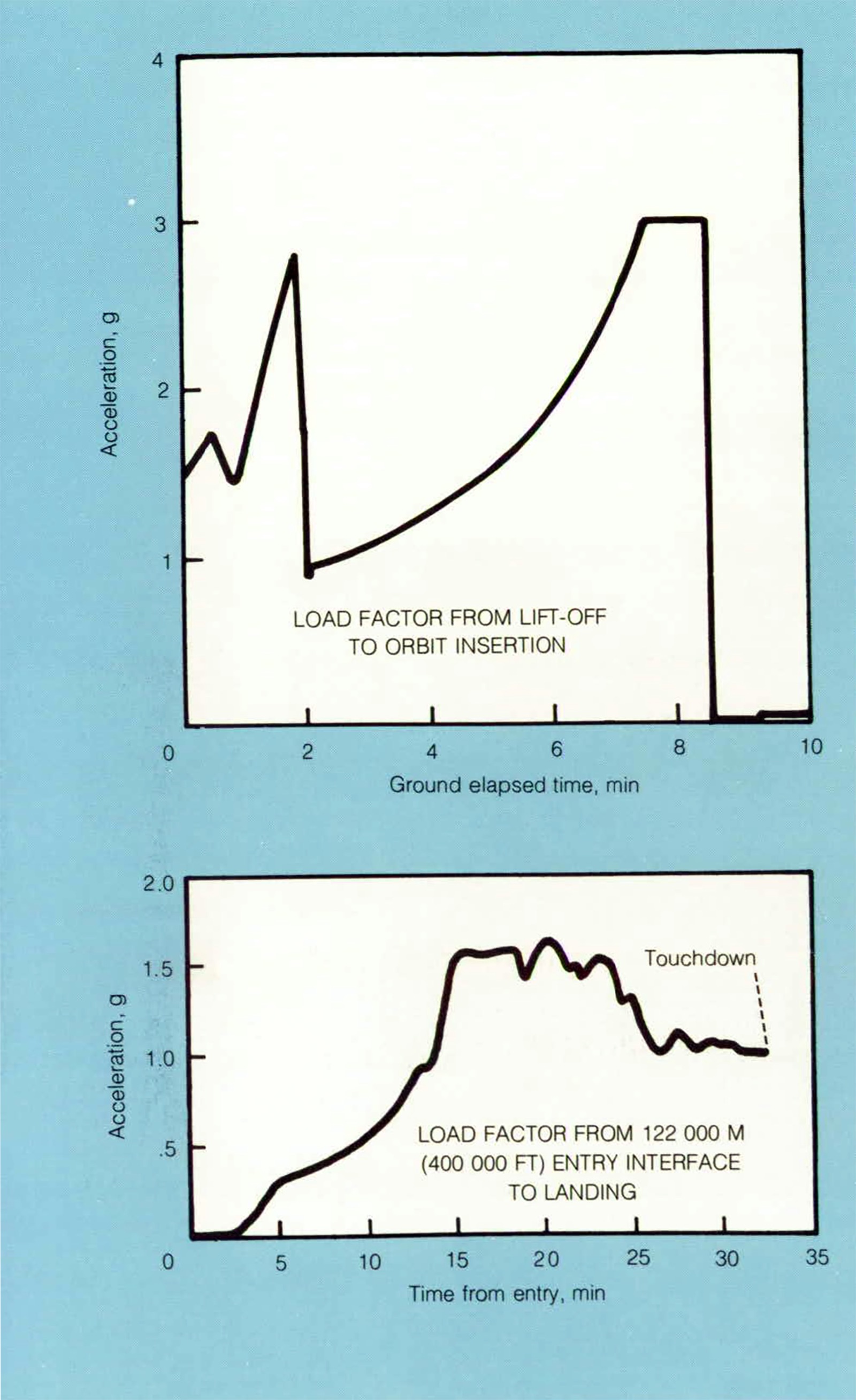

Crew members and passengers will experience a designed maximum gravity load of only 3g during launch and less than 1.5g during a typical reentry. These accelerations are about one-third the levels experienced on previous manned flights. Many other features of the Space Shuttle, such as a standard sea-level atmosphere, will welcome the nonastronaut space worker of the future.

WIDE VARIETY OF MISSIONS

The Space Shuttle has the capability to conduct space missions in response to currently projected national and worldwide needs and the flexibility to respond to policy, discovery, and innovation. The primary mission for the Space Shuttle is the delivery of payloads to Earth orbit. The shuttle system can place payloads of 29500 kilograms (65,000 pounds) into orbit. Payloads with propulsion stages can place satellites into high Earth orbit or into lunar or planetary trajectories.

The Space Shuttle is more than a transport vehicle. The Orbiter has the capability to carry out missions unique to the space program: to retrieve payloads from orbit for reuse; to service or refurbish satellites in space; and to operate space laboratories in orbit. These capabilities result in a net savings in the cost of space operations while greatly enhancing the flexibility and productivity of the missions.

Among the multifaceted uses of Space Shuttle during its operational life, which will extend beyond the 1990’s, will be a wide range of applications of the environment of space and of space platforms. The applications can be achieved through operation of satellites, satellites with propulsion stages, space laboratories,or combinations as appropriate to the specific objectives and requirements. The Shuttle also provides a laboratory capability to do research and to develop techniques and equipment that may evolve into new operational satellites.

The Space Shuttle will not be limited to uses that can be forecast today. The reduction in the cost of Earth-orbital operations and the new operational techniques will enable new and unforeseen solutions of problems.

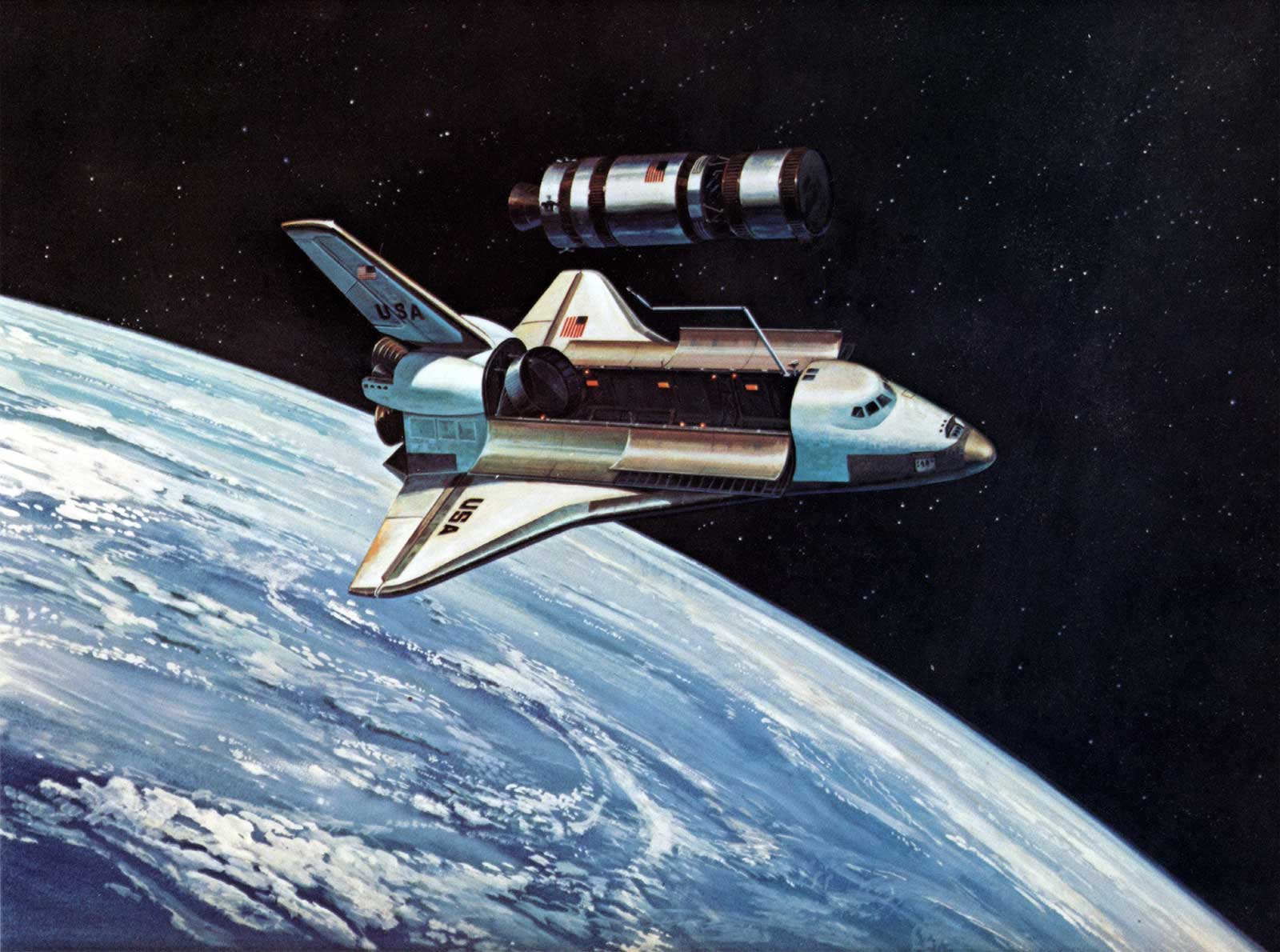

PLACEMENT AND RECOVERY OF SATELLITES

One important Space Shuttle mission will be the placement of satellites in Earth orbit. A satellite launched on a previous mission can be retrieved and returned to Earth for refurbishment and reuse.

As many as five individual satellites may be delivered on a single mission. The satellites are serviced, checked out, and loaded into the Orbiter. The crew will consist of Shuttle pilots and mission and payload specialists. Upon reaching the desired orbit, the mission and payload specialists will conduct predeployment checks and operations. After determining that the satellite is ready, the crew will operate the payload deployment system, which lifts the satellite from the cargo-bay retention structure, extends it away from the Orbiter, and releases it. The final activation of the satellite will be by radio command. The Orbiter will stand by until the satellite is performing satisfactorily before proceeding with the remainder of the mission.

To recover a satellite, the Orbiter will rendezvous with it, maneuver close, and grab it with the remote manipulator arm. After the satellite is deactivated by radio command, it will be lowered into the cargo bay and locked into place. The Orbiter will perform deorbit maneuvers, enter the atmosphere, and land, returning the expensive satellite for reuse.

PLACEMENT OF FREE-FLYING SCIENTIFIC LABORATORIES IN SPACE

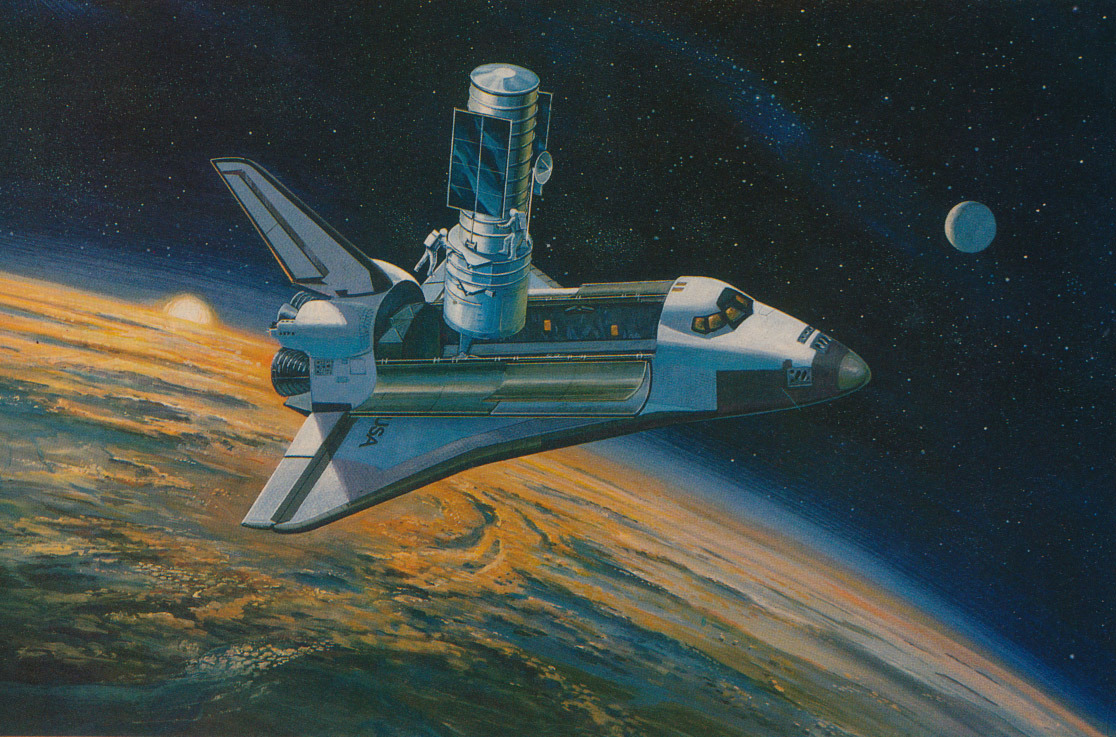

The space telescope represents an international facility for on-orbit space research controlled by the investigating scientists on the ground. Design studies are now being conducted and sponsored by the NASA Marshall Space Flight Center and the Goddard Space Flight Center. The Space Shuttle would deliver the telescope to orbit, and the crewmen assist in preparing the facility for operation. During scheduled revisits to the facility, the Space Shuttle crewmen would service supporting subsystems, exchange scientific hardware, and, several years later, return the facility to Earth at the end of its mission.

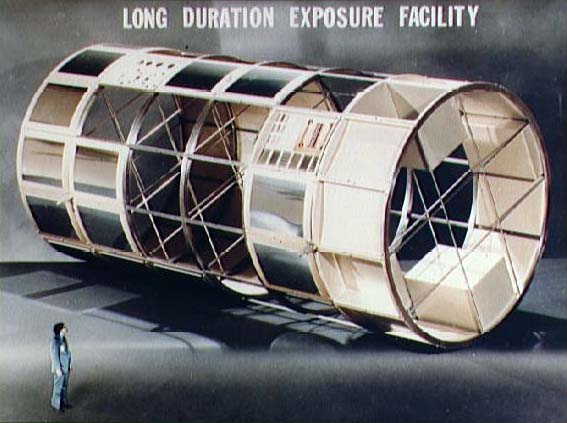

The long duration exposure facility (LDEF) is a basic research project being implemented by the NASA Langley Research Center. The LDEF is a reusable, unmanned, low-cost, free-flying structure on which a variety of passive experiments can be mounted to study the effects of their exposure to space over a relatively long period of time. After an extended period in orbit, the LDEF will be retrieved by an Orbiter and returned to Earth for experiment analysis.

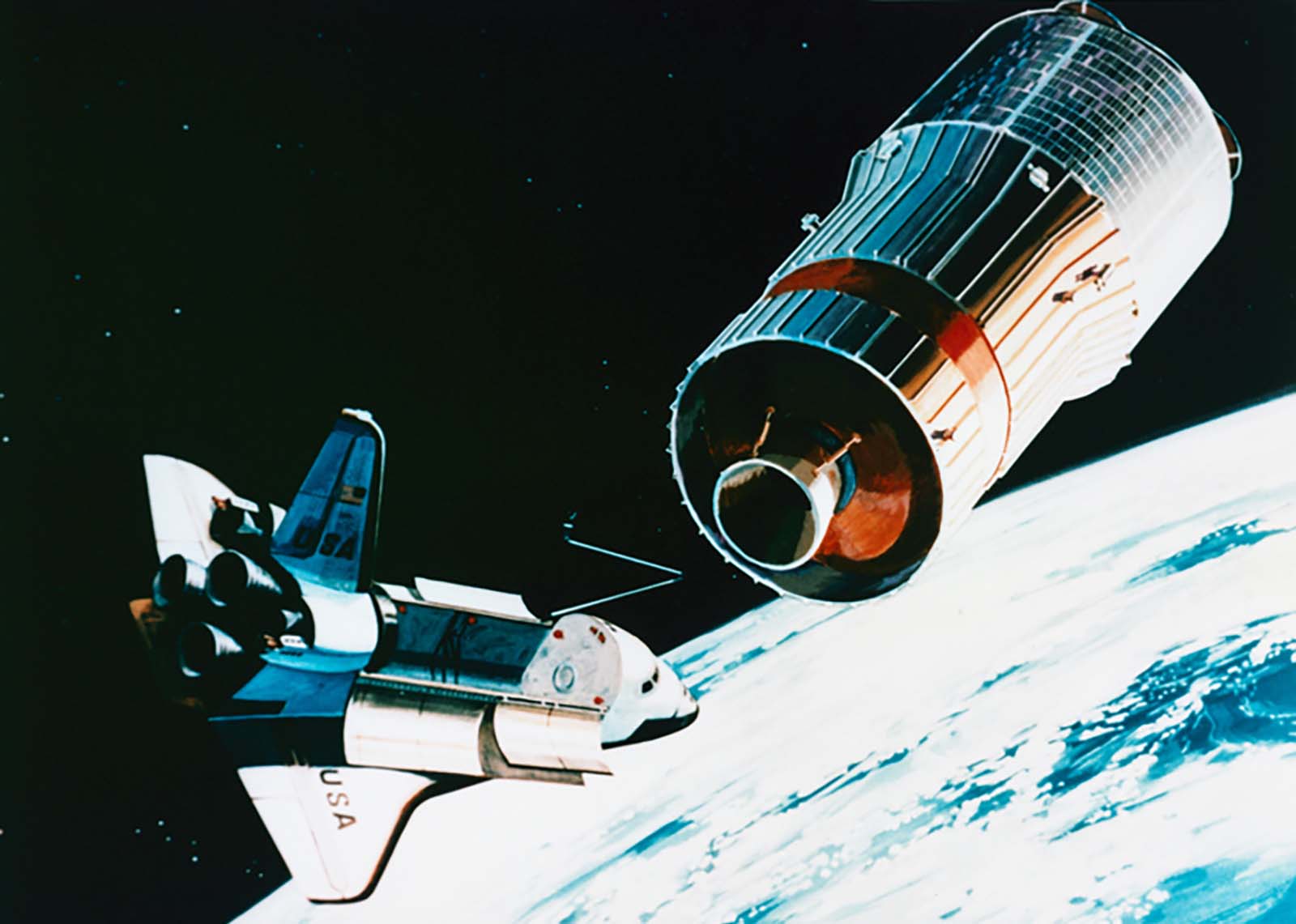

DELIVERY OF PAYLOADS THAT USE PROPULSION STAGES

Major activity is forecast for geosynchronous orbits, deep-space missions, elliptical orbits, and higher circular orbits. Payloads with such destinations will require a propulsion stage in addition to the Shuttle. Both the satellite and the propulsion stage will be delivered to orbit and deployed as illustrated. Before release, the combined propulsion-stage/satellite system will be checked and readied for launch, and guidance information will be updated. The Orbiter will move a safe distance away before ground control gives radio command signals to fire the propulsion stage engines.

The Shuttle payload crew can do both visual and remote monitoring. In the event of a malfunction, the stage and satellite can be retrieved for inspection and possible repair. Should it be determined that repair is beyond the onboard capability, the entire payload (propulsion stage and satellite) would be returned to Earth for refurbishment.

Initially, a solid propulsion stage will be adapted for this on-orbit launch. This first design, referred to as interim upper stage (PUS), is not reusable but could lead to fully reusable propulsion stages in the future.

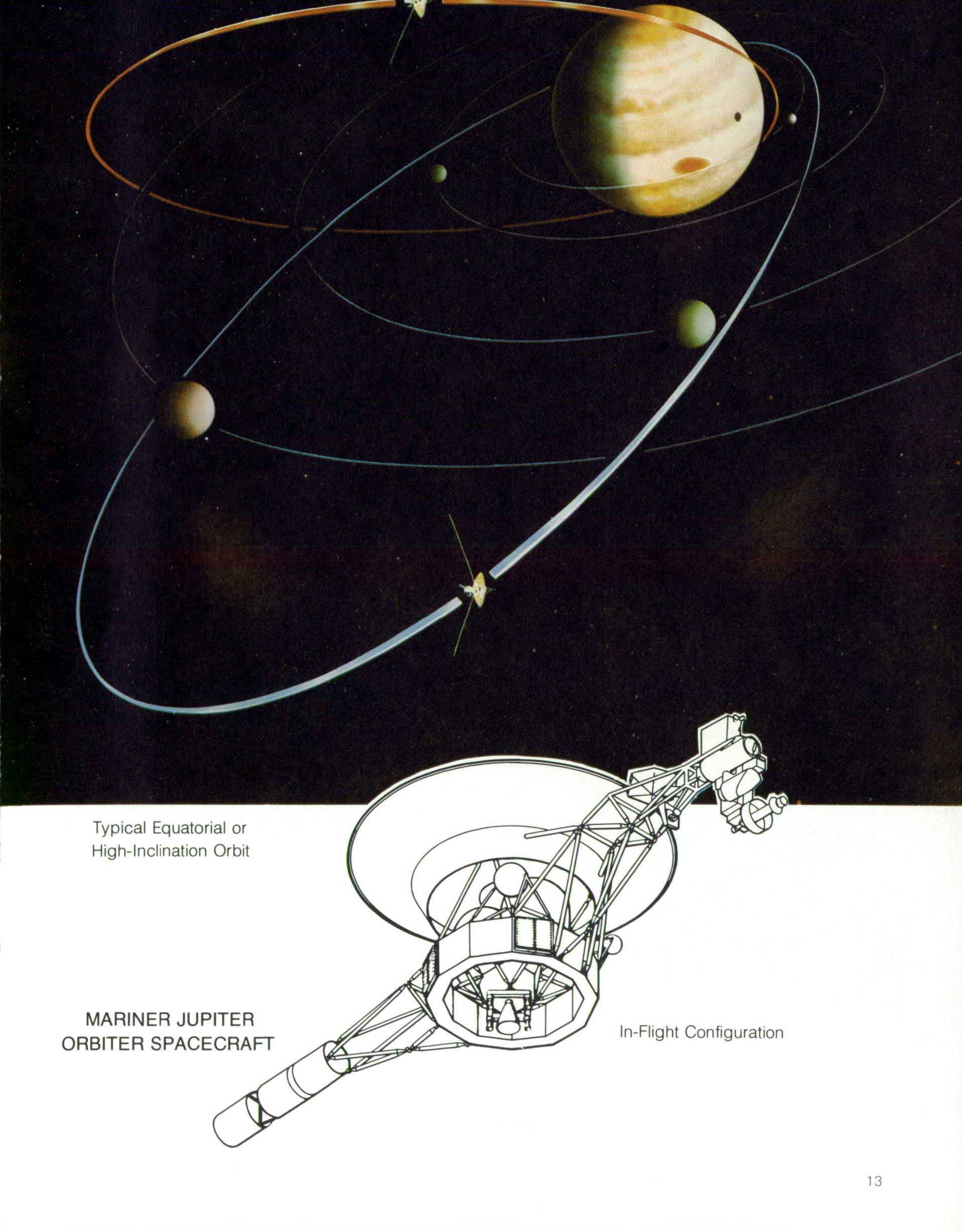

The Mariner Jupiter Orbiter/IUS will be launched by the Shuttle in the mid-1980’s for the purpose of obtaining additional data about the planet Jupiter, its satellites, and the space surrounding it.

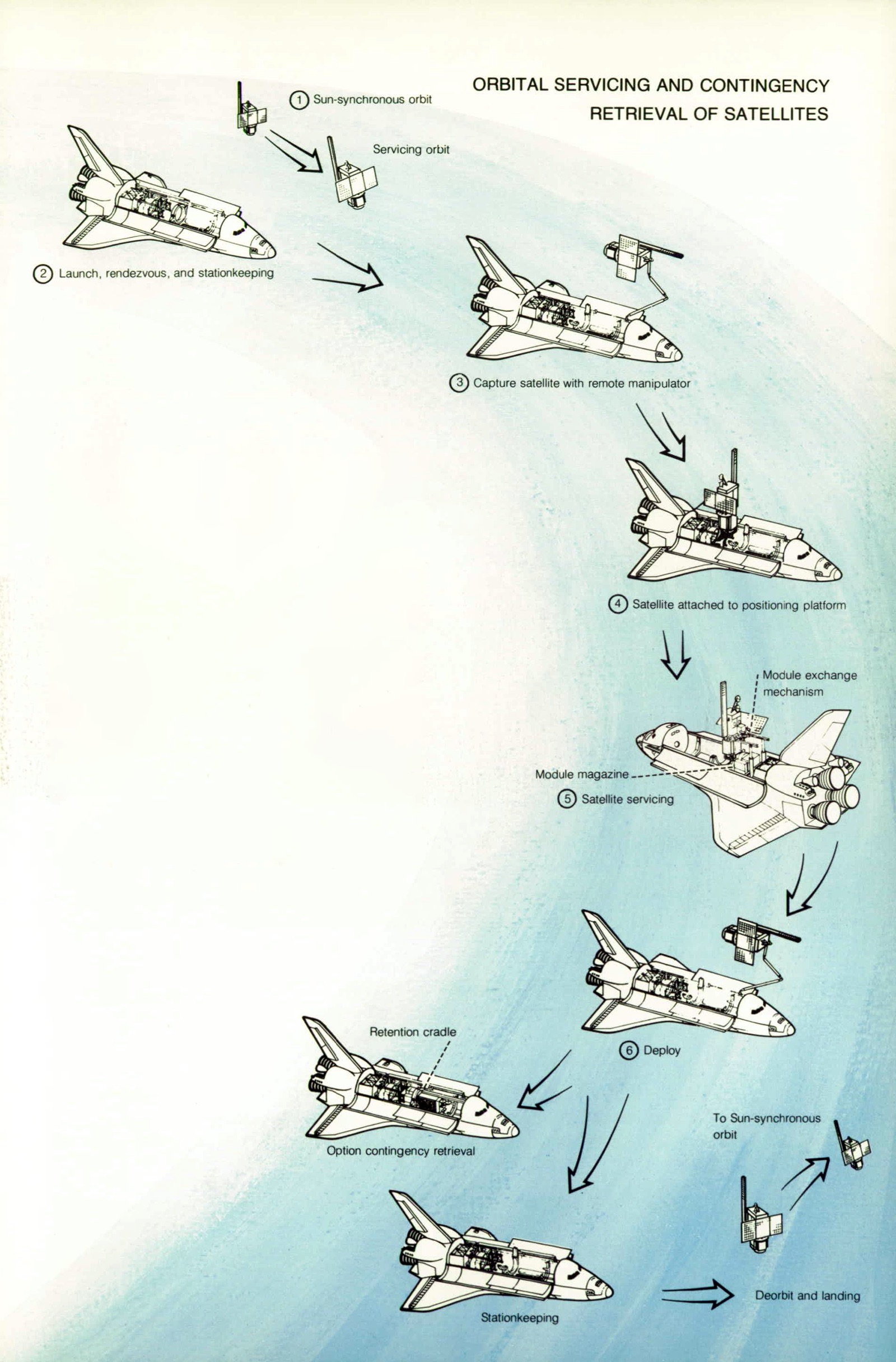

ON-ORBIT SERVICING OF SATELLITES BY THE SPACE SHUTTLE

The NASA Goddard Space Flight Center is studying a family of modular spacecraft satellites to be placed in orbits of various inclinations and altitudes. The low-cost standard hardware is expected to comprise much of each satellite. Among other features, the design of this hardware will provide for on-orbit servicing by changeout of supporting subsystem assemblies and applications sensors. These system features, in association with the Shuttle-based equipment and Shuttle operational techniques, will permit on-orbit maintenance and updating of this family of satellites. Combined with the large weight and volume capacity of the Shuttle, this capability provides the payload designer new freedom in developing and operating satellites that can reduce payload costs as well as improve performance.

Alternative techniques for on-orbit servicing of satellites are under study. The approach illustrated is based on current simulations of prototype hardware with replaceable modules. Low-cost returbishable payloads are carried by a retention system which supports all boost, reentry, and landing loads. This type of payload, a modular satellite designed for Earth observations, is shown in the cargo bay of the Orbiter. The retention system pivots a docking ring to allow rotation of the satellite in and out of the cargo bay. Deployment away from the Orbiter or capture and berthing of a stabilized satellite are accomplished by the manipulator arms attached to the Orbiter. To replace the module, a rotary magazine carrying the replacement modules presents them at the proper time to an exchange mechanism. The exchange mechanism removes the old module from the satellite and stows it temporarily, removes the new module from the magazine and installs it in the satellite, and then stows the old module in the rotary magazine

SPACELAB AND ORBITER INTERNATIONAL COOPERATION IN SPACE

This is an unprecedented cooperative enterprise which represents a most generous contribution by the European nations to the basic space facility of the 1980’s, one which we can use in common on either a cooperative or reimbursable basis as circumstances warrant.

James C. Fletcher NASA Administrator

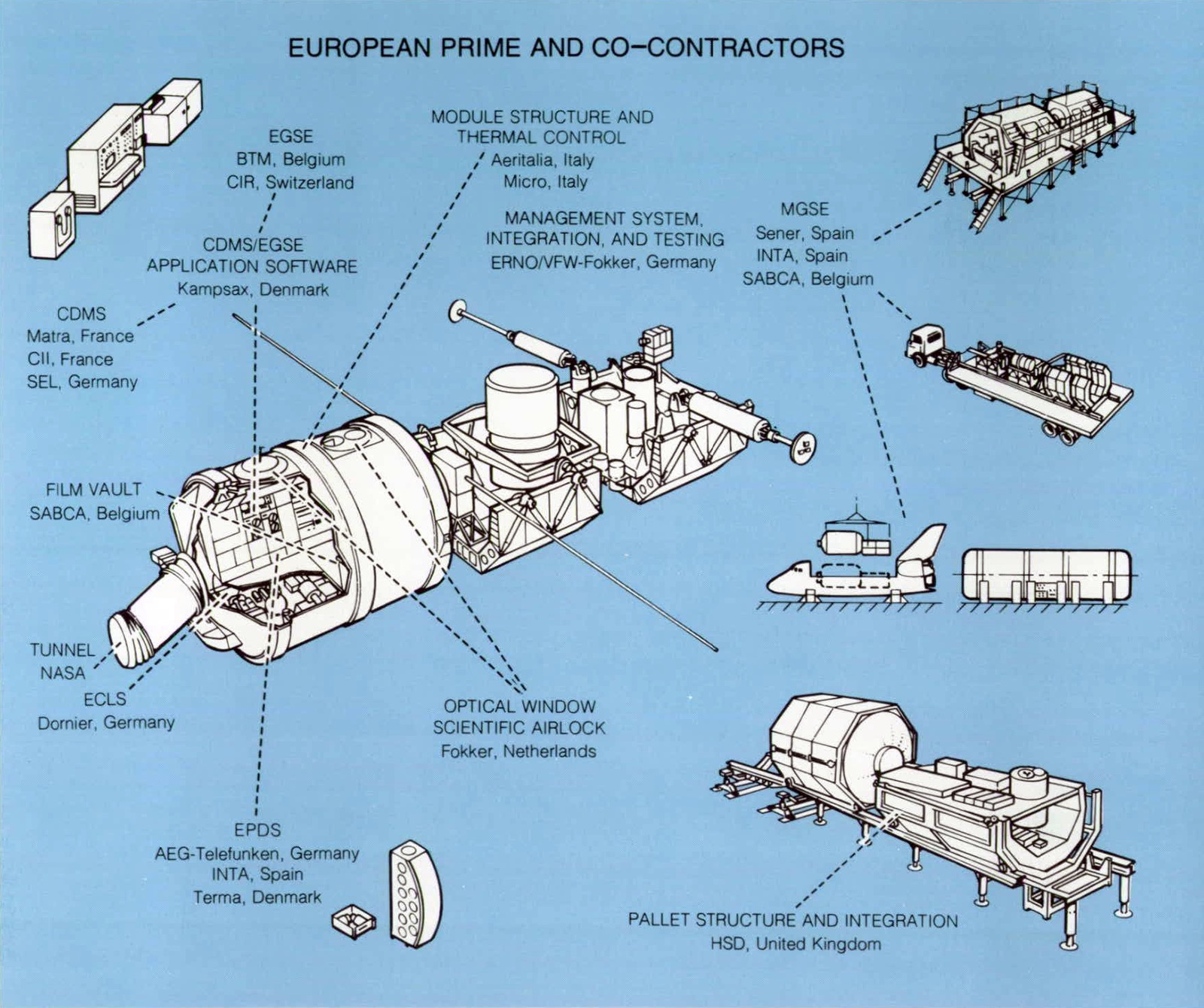

Spacelab is an international program being developed by the European Space Agency (ESA). The large pressurized Spacelab module with an external equipment pallet will be a frequent payload carrier during the Space Shuttle era. Spacelab will provide an extension of the experimenter’s ground-based laboratories with the added qualities which only space flight can provide, such as a long-term gravity-free environment, a location from which Earth can be viewed and examined as an entity, and a place where the celestial sphere can be studied free of atmospheric interference.

Several Spacelab system configurations will be flown. The configuration illustrated includes a pressurized module where experimenters can work in a shirt-sleeve environment. A tunnel connects the Orbiter crew compartment with the Spacelab. Instruments can be mounted on a pallet aft of the pressurized module if they require exposure to the space vacuum or are too bulky to place inside or for convenience in viewing. The Orbiter may be flown in an inverted attitude to orient the instruments toward Earth for surveys of Earth resources and for investigations of geophysical and environmental parameters.

Other Spacelab configurations include those which, in place of a pressurized module, have a large pallet on which numerous instruments are installed and controlled from the payload specialist’s station within the Orbiter. Pressure-suit operations in the payload bay are practical when instrument service is required.

Ten member nations of the European space community have agreed to commit almost $500 million to design and deliver one flight unit to the United States. Agreements provide for purchase of additional units by the United States. Cooperating nations are West Germany, Italy, France, United Kingdom, Belgium, Spain, the Netherlands, Denmark, Switzerland, and Austria. Many types of scientific, technological, medical, and applications investigations can be accomplished with this flight hardware. Each Spacelab is designed to be flown as many as 50 times over a 10-year period. This system will provide an entirely new capability for manned participation, which will increase the effectiveness of space research as well as reduce the cost of the application of space technology.

Some crewmembers and payloads for Spacelab will be international in origin and others will be provided by U.S. Government and industry