Chapter 7

Man-Rating the Machines

(July - December 1959)

SADDLING ballistic missiles for manned space flight was in some respects like trying to ride Sinbad's roc: the bird was not built for a topside burden, and man was not meant for that sort of punishment. Once accepted in theory that this fabulous bird could be domesticated and that some men could tolerate, even enjoy, the strains and stresses of such a ride, practical questions of marrying the separate abilities of man and machine demanded immediate answers. Engineers in the Space Task Group and other NASA researchers at Langley, Lewis, and Ames were providing some of these answers; engineers and technicians in industry and in quasi-military organizations contributed equally important answers. The primary task of the Task Group managing Mercury was to ask the right questions and to insist on better answers from the industrial producers of the parts and from the academic, industrial, and military suppliers of services.

In the latter half of 1959, as STG monitored the gathering momentum of the various manufacturers, the urgent search for ways to reduce the ultimate risk of sending a man for a ride in an artificial moon lifted by a missile gradually became more systematic and better organized. The theme of this chapter is the quest for reliability in the automatic machinery developed for the Mercury mission. Making these devices safe enough for man took longer and exposed more doubts than STG had expected originally. During the curiously quiet first half of 1960, the flexibility of the Mercury astronaut complemented and speeded the symbiosis of man and missile, of astronaut and capsule. Technology, or hardware, and techniques, or procedures - sometimes called "software" by hardware engineers - both had to be developed. But because they were equally novel, reliability had to be built into the new tools before dexterity could be acquired in their use.1

At the beginning of 1959 NASA Headquarters had worried about three scientific unknowns needing resolution before actual attempts to conduct manned orbital flights. In their contribution to a House Committee Staff Report prognosticating for Congress on The Next Ten Years in Space, 1959-1969, Administrator T. Keith Glennan and the chief scientists at the helm of NASA in Washington listed these imperatives that must be investigated before man could go into space:

The problems known to exist include (1) high-energy radiation, both primary and cosmic ray and the newer plasma type discovered in the IGY satellite series; (2) man's ability to withstand long periods of loneliness and strain while subjected to the strange environment of which weightlessness is the factor least evaluated; and (3) reentry into the atmosphere and safe landing. The reliability of the launching rocket must be increased before a manned capsule is used as a payload. Once these basic questions have been answered, then we can place a manned vehicle in orbit about the earth.2

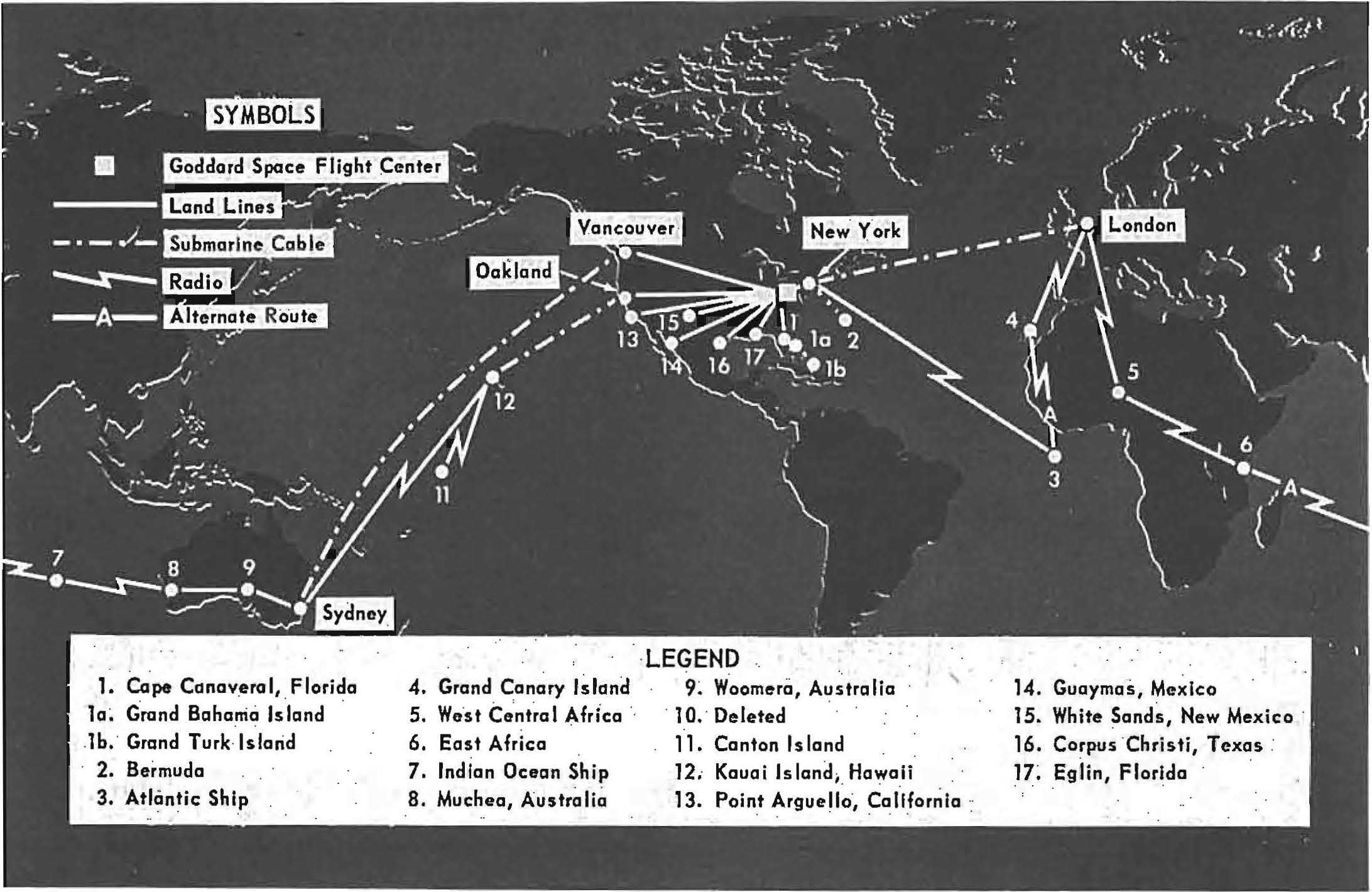

By July 1959 the engineers in the Space Task Group were no longer concerned by the unknowns in each of these problematic areas. They had obviated the need for high-energy radiation shielding by selecting a circular orbit around the equatorial zone at an altitude between 80 and 120 miles, well above the stratosphere and well below the Van Allen belts. Loneliness would be no problem because the communications network would keep the astronaut in almost constant voice contact with ground crews. Weightlessness, to be sure, was the factor least evaluated, but by now this was the prime scientific variable that Project Mercury was designed to answer. The psychological outlook was good anyway, argued STG rhetorically, for does not everyone who has learned to swim enjoy the freedom and relatively "weightless" state when immersed in water? As to reentry, the strain of positive and negative acceleration forces had almost certainly been conquered; only a few questions remained unanswered about actual reentry and recovery stresses. Indeed, what Headquarters had left unnumbered in its presentation and therefore seemed to have regarded almost as an afterthought, the Task Group considered the paramount problem: the reliability of the rocket boosters must be increased before manned capsules could be attached to them.

The first major proof test of a critical part of the Mercury spacecraft design occurred on April 12, 1959. After a dismal failure a month before, the escape-tower rocket attached to a full-scale boilerplate model demonstrated it ability to lift both man and capsule away from a dangerous booster still on the ground. Giving first priority to providing an escape system in case of failure at launch was evidence of a pervading lack of confidence in the reliability of the big rockets. The men of the Space Task Group were not liquid-fuel propulsion experts; they had to rely on missile technicians and managers to convert weapon systems into launch vehicles for spacecraft. Since no one was expert in spacecraft engineering, STG had to rely on itself and on McDonnell Aircraft Corporation to gain as much experience as rapidly as possible with the capsule and its systems. This high adventure of learning how, specifically, to orbit a man safely was shared by a growing number of people supporting Project Mercury.

Mercury Team Takes Shape

Although Robert R. Gilruth's Space Task Group was growing rapidly, it remained small enough and intimate enough throughout 1959 to make everyone feel his worth. The creative engineering challenge of the project inspired an esprit that could be measured by the amount of voluntary overtime and vacation time relinquished by the members of STG. Gilruth's administrative assistant for staff services, 46-year-old Paul D. Taylor, died of a heart attack in May and was mourned by his colleagues as a martyr who overworked himself in the cause.3

According to its own estimates of present and future manpower requirements, the Task Group was hard pressed to meet all its commitments in mid-1959. At the beginning of the new fiscal year on July 1, NASA authorized the Task Group to hire another 100 persons, mostly recent college graduates. A total of 488 authorized positions was to be filled by the end of the calendar year. But STG argued that only one of its three major divisions at work on Mercury - Operations, under Charles W. Mathews - was fairly equal in numbers to the tasks at hand so far. The Flight Systems Division, under Maxime A. Faget, was called "greatly understaffed," and the Engineering and Contract Administration Division, now under the acting leadership of the Canadian James A. Chamberlin, was in "such urgent need" of more technical and administrative help that the Space Task Group requested 200 additional positions, to be filled within the next three months. Estimates of increased Langley and Lewis support activities for Project Mercury almost doubled this personnel request. The sheer size and immense scope of industrial and military personnel required to support Mercury stirred STG to a premonition of precarious control:

In summary, a detailed study of staffing requirements for Project Mercury shows that the presently authorized complement of 388 should be increased by 330 positions during fiscal year 1960 in order to maintain the project schedules. This staff of 718 should be available by September of 1959, but orderly recruitment and integration of the additional staff would defer the filling of the complement until April of 1960. It is believed that everything practicable in the line of contracting on Project Mercury has been done without going to the extreme of effectively relinquishing control of the project. Failure to obtain the additional personnel shown must result in either major slippage of the schedule or in NASA effectively losing control of the project to the military or to industry.4

Because there was still no official commitment to manned space flight programs beyond Mercury and because hope was still high that manned orbital flight could be accomplished by the end of 1960, the Task Group accepted its temporary status and planned to phase out the people working on Project Mercury beginning in June 1961. Such plans were tentative, of course, and did not reckon with the technical and organizational problems that were to stretch out the program, nor with the astronautical and political events that were to change the course and expand the role of NASA's manned space flight efforts in 1961.

Nevertheless, by early August 1959, Gilruth was able to put his own field element of the Goddard Space Flight Center in much better order through a major reorganization.5 His new title, Director of Project Mercury, was indicative of the expanded size and activity of the Task Group. The functions of "project manager" for engineering administration devolved upon Chamberlin, who also headed the new Capsule Coordination Committee. Addition of staff services and elaboration of branch and section working group leaders after August 3 made STG's organization charts much more detailed. But the block diagrams, while helpful to new recruits and to industrial visitors at the crowded old brick administration building at the eastern entrance to Langley Field, showed rather artificial separations of activity and authority within STG. The intimacy of the original group had suffered inevitable attrition as the result of an eightfold increase in size in less than a year, but the "inner circle" still operated personally rather than formally. Outside relationships, even those with Langley Research Center, on the other side of the airbase, were rapidly demanding more formality.

A partial solution to these problems, which in time grew to be one of the most important organizational decisions ever made for Project Mercury, was the informal agreement made in August 1959 between the Defense Department and NASA to select two men to act as "single points-of-contact." DOD appointed Major General Donald N. Yates, Commander of the Air Force Missile Test Center, to become in October its representative for military support activities for Project Mercury. The job of mobilizing and coordinating such diverse activities as Air Force prelaunch and launch support, Navy search and recovery operations, Army tracking and communications facilities, and joint service and bioastronautics resources demanded systematic, formal organization.6 In turn, Hugh L. Dryden for NASA asked the chief of the High Speed Flight Station, Walter C. Williams, to join Gilruth to act as the contact point with Yates. Effective September 1, 1959, Williams and his colleagues Kenneth S. Kleinknecht and Martin A. Byrnes accepted transfers from NASA's High Speed Flight Station - shortly to be renamed the NASA Flight Research Center - to the Space Task Group. Having pioneered since 1945 in airborne launches of rocket research aircraft, Williams was a senior convert to the vertical ground launch cause of Mercury. Faget especially welcomed him. A personable and forceful leader, Williams took a position on a level with Charles J. Donlan. Each was an associate director for Project Mercury, Williams specializing in operations and Donlan in development. Williams had guided the NACA-NASA role in the flight operations of the X-15 rocket plane to a point just two days short of its first powered flight, on September 17, with North American Aviation's test pilot A. Scott Crossfield at the controls. When Williams, Kleinknecht, and Byrnes took up the higher national priority and professional challenge of working with spacecraft rather than aircraft, they brought to STG valuable operational and development experience with the highest-performance manned flight vehicles then in existence.7

Although there was pressure to get on with operations planning, engineering the Mercury capsule was still the primary task during these days. McDonnell and STG had swapped permanent field representatives during the spring in the persons of Frank G. Morgan and Wilbur H. Gray. Morgan came to live in a motel at Langley. Gray found a residence in St. Louis near the north side of Lambert Field, where the McDonnell plant was spread around the perimeter of the municipal airport. Though their technical liaison work was heavy, Morgan and Gray acted as hosts and guides as much as consultants, because visits by exchange delegations of engineers were so frequent. Just as the coordination of these meetings and trips for the development of the capsule became imperative among the aircraft and spacecraft designers and developers, so were closer, more orderly relations required with the developers of the ballistic missile boosters. Aerospace engineers often used one word to express the adaptation of systems, modules, organizations, and even technologies to one another: that word was "interface"; it connoted problems of integration, convergence, and synthesis of indeterminate magnitude.

Converging Technologies

The problem of man-rating the Redstone rocket was tackled with characteristic gusto by Joachim P. Kuettner, the man Wernher von Braun had called in 1958 to lead the Army's effort if Project Adam had been authorized. Kuettner had earned doctorates in law, physics, and meteorology before he became a flight engineer and test pilot for Messerschmitt during the Third Reich. Having been one of the first to test a manned version of the V-1 in 1944, Kuettner had made further use of his avocation as a jet aircraft and sailplane pilot for the U.S. Air Force Cambridge Research Center before joining the Army Ballistic Missile Agency (ABMA) at Huntsville.

In retrospect Kuettner has generalized about the problem of "Man-Rating Space Carrier Vehicles" in terms relating his experience with both aviation and missile technologies:

While it is admittedly an oversimplification, the difference between the two technologies may be stated in the following general terms. From an aviation standpoint, man is not only the subject of transportation, and as such in need of protection as a passenger; but he is also a most important integral part of the machine over which he truly has control. His decisions in expected and unexpected situations are probably the greatest contributions to his own safety. Aviation, to the best of our knowledge, has never seen the necessity for a fully automatic initiation of emergency escape.

In contrast, rocket technology has been for 20 years a missile technology governed by the requirements of target accuracy and maximum range. As such, it had to develop automatic controls. Unlike a human payload, a warhead has no use except on the target. Once the missile fails, it may as well destroy itself during flight. (For this reason, missilery has accepted aerodynamically unstable vehicles which, in case of loss of thrust, flip over and break apart, destroying themselves in the air.) There has been no need to save the payload after a successful flight or in case of a catastrophe.

The development of manned space flight is not just a matter of replacing a warhead by a manned cabin. Suddenly, a switch is thrown between two parallel tracks, those of missile technology and those of aviation technology, and an attempt is made to move the precious human payload from one track to the other. As in all last-minute switchings, one has to be careful to assure that no derailment takes place.8

In the spring of 1959, while Kuettner was still signing himself the "Adam-NASA Project Engineer," he and his deputy, Earl M. Butler, began a series of triangular conferences, with Kurt H. Debus and Emil P. Bertram of ABMA's Missile Firing Laboratory at the Cape, in one corner, and Charles Mathews and Jerome B. Hammack, the Mercury-Redstone project engineer for STG, in the Langley corner. Between these informal discussions and six formal study panels inaugurated by von Braun, a consensus was supposed to arise on, among other things, the sort of emergency detection system necessary to warn of impending cataclysms in the booster and to trigger some sort of automatic ejection. Preliminary agreements on a design for an abort or safety system began early in good accord. But the uncertain reliability program, booster recovery proposal, capsule design changes, and electrical interface problems fouled the subsequent development of the Redstone abort-sensing system.9 In this respect the Atlas was more nearly ready than the Redstone by the end of the year.

Many factors contributed to the slippage in the Mercury-Redstone schedule, but one significant cause for delay grew out of a subtle difference between ABMA and STG in their approach to pilot safety and reliability. The role of the astronaut was clearly at issue here longer than anywhere else. Conditioned by their designs for Project Adam, the Huntsville rocketmen thought of the astronaut throughout 1959 as merely an "occupant" or "passenger." The Adam proposal for an escape system during off-the-pad aborts would have ejected a biopack capsule laterally into a tank of water alongside the launch pad. Having less trust than STG in the reliability of "Old Reliable," the Redstone engineers insisted on putting safety first and making it fully automatic wherever possible. Reliability, they insisted, is only a concept and should be secondary to safety. This attitude was illustrated in the introductory paragraphs of the ABMA proposal for the Redstone emergency detection system. The author, Fred W. Brandner, began by saying that the use of missiles for transporting man would demand an automatic escape system to assure pilot safety:

This system has to rely on emergency sensors. There are an enormous number of missile components which may conceivably fail. Obviously, it would be impractical and actually unsafe to clutter up the missile with emergency sensors. However, many malfunctions will lead to identical results, and, in sensing these results and selecting the proper quantities, one can reduce the number of sensors to a few basic types.10

The Mercury astronauts received their first detailed briefing on the Redstone booster at the Army Ballistic Missile Agency, Huntsville, Ala., in June 1959. Facing the briefer, Joachim P. Kuettner, the Mercury-Redstone project engineer under von Braun, are: left to right, Glenn, Shepard, Schirra, Carpenter, Slayton, Grissom, and Cooper. Kuettner touches the fin-stabilized Redstone model, explaining the purpose and construction of the carbon jet vanes barely visible below the single engine nozzle.

Brandner proposed to measure only three basic quantities: the control system attitude and angular velocity, the 60-volt control and 28-volt general electrical power supplies, and the chamber pressure of the propulsion system. To ensure "a high degree of passenger (pilot) safety" on the Mercury-Redstone rocket, if operational limits set on these sensors should ever be exceeded the capsule would eject from the booster and be lowered by parachute.

Brandner's modest proposal stated the issue but not the solution to the general question of man-machine relationships in Project Mercury. In 1959 the technical debate was still inextricably mixed up with previous attitudes toward the precise role of man in a manned satellite. Could the pilot test the vehicle or should the vehicle test the pilot? Mercury was NASA's program and STG's responsibility, but at this stage of development the military establishment and missile industries still knew, or thought they knew, more about the technological path for man's first climb into space than NASA-STG did.11

From the Pentagon, for example, Brigadier General Homer A. Boushey, Director of Advanced Technology for the Air Force, had predicted in January that the most important key to space flight in the next decade would be not simply manned but rather piloted spacecraft:

By piloted spacecraft, I refer to a vehicle wherein the pilot operates controls and directs the vehicle. This is quite a different concept from the so-called man-in-space proposal which merely takes a human "along for the ride" to permit observation of his reactions and assess his capabilities. The high-speed flight experience of the NACA and the Air Force has shown that piloted craft return research data more effectively and more economically than do unmanned vehicles. While there is a place, certainly, for automatic, instrumented vehicles, I believe man himself will prove "the essential payload" to the full utilization of space. Orbital rendezvous, controlled landing after reentry, and space missions other than the simplest sensing and reporting type, will require man. If for no other reason than that of reliability, man will more than pay his way.12

Boushey's percipient remarks illustrated the persistent residue of misunderstanding remaining from interagency competition for the manned satellite project in the pre-NASA, pre-Mercury period. Task Group officials felt compelled to defend the distinctive nature of Mercury and to emphasize that NASA astronauts were never intended to be passive passengers. Rather, they were to prove their full potential as pilots, within limits prescribed by the mission requirements programmed into the automatic systems. Although there were long and hard arguments within STG as to whether man should be considered "in the loop" or "out of the loop" in performing various tasks, the preponderance of NACA-bred aeronautical engineers in STG usually voted for as active an astronaut as possible.

Outside pressures from scientists and missile engineers also helped unify and consolidate opinion within STG. The distinguished research chief of Bell Telephone Laboratories and one of the fathers of communication satellites, John R. Pierce, summed up the argument for automation: "All we need to louse things up completely is a skilled space pilot with his hands itching for the controls."13

The problem of man-rating the Atlas was preoccupying another task force of still larger proportions than the one concerned with the Redstone. The industrial and military engineers in southern California and at the Cape who were trying to make the Atlas meet its design specifications could and did mobilize more resources than either STG or ABMA could command. A few individuals stood out as leaders in the vast effort. Kuettner's counterpart for the AirForce was Bernhard A. Hohmann, another former test pilot at Peenemünde West, who had been project engineer on the first two models of the Messerschmitt-163, one of the first rocket-powered aircraft. In August 1959, Major General Osmond J. Ritland of the Air Force Ballistic Missile Division (BMD) assigned him the job of supervising the systems engineering at Space Technology Laboratories (STL) for a pilot safety and reliability program on the Mercury-Atlas series. As Brandner did for the Redstone, D. Richard White, an STL electronics engineer, made the preliminary designs for the Atlas emergency detection system. White was inspired, he said, "one Sunday in May when I imagined myself sitting atop that bird." Edward B. Doll, STL's Atlas project manager, could never imagine anyone foolish enough to sit on an Atlas, but he allowed Hohmann and White to proceed with their commitments.14 STL performed an overall technical direction over the associate contractors for the Atlas similar to that performed by STG for NASA, but with significant differences. STL had not been involved in the original MX-774 design behind the Atlas, and although it became closely associated with conceptual development of Atlas as a weapon, ultimate responsibility remained with the Air Force Ballistic Missile Division. Both STL and STG were systems engineering organizations, but STG had a deeper background in research and was directly responsible for the development of the project it managed; STL had broader experience in systems engineering, missile development, and business management.

Hohmann and his assistant, Ernst R. Letsch, huddled closely with the reliability statisticians at STL, led by Harry R. Powell, and with BMD's Mercury project liaison officer, Lieutenant Colonel Robert H. Brundin, also appointed by Ritland in August 1959. But the main responsibility for detail design, development, and production work fell on the shoulders of the manufacturers, General Dynamics (formerly Convair)/Astronautics (GD/A or CV/A) of San Diego. The details, tooling, and implementation of the emergency detection or abort sensing system for the Atlas were guided by Charles E. Wilson, Tom E. Heinsheimer, and Frank Wendzel. Their boss, Philip E. Culbertson, the Mercury project manager for General Dynamics/Astronautics, conferred repeatedly and sometimes heatedly with Hohmann, Brundin, Doll, and his own factory production engineers, John Hopman, Gus Grossaint, Frank B. Kemper, and R. W. Keehn.15

Here, too, a triangular dialogue was going on during initial considerations for man-rating the Atlas. But STG engineers were far away, busy with other matters, and knew well how little they knew about the Atlas. NASA and the Air Force, like STG and the Army, informally had agreed to divide developmental responsibility and labor at the capsule-separation point in the trajectory. So STG was not directly involved in the tripartite workings of the so-called "BMD-STL-GD/A complex" in southern California.

Looking at Project Mercury from the West Coast in 1959 gave a set of very different perspectives on the prospects for accomplishing the program on time and in style. South of Los Angeles International Airport there was no consensus and precious little communication of the confidence felt across the continent on the coast of Virginia. But STL, Convair, and Air Force representatives at the Cape gradually diffused some of the contagious enthusiasm of STG while commuting between home and field operations. More important still, the sense of desperate military urgency to develop an operational ICBM still pervaded the factories and offices devoted to the Atlas in southern California. Motivation already mobilized might easily be transferred if only the Atlas could be proved by the end of the year. STG was more sanguine about this forthcoming proof than the Atlas people, and NASA Headquarters seemed even more optimistic.

Perhaps symbolic of the profound Air Force distrust of the "bare Atlas" approach and indicative of lingering doubts about the competence of the STG neophytes who had stolen the march on man in space was the acronymic name imposed by Air Force officers on the abort sensing system. White and Wilson wanted to call it simply the Atlas "abort sensing system." No, someone in authority insisted, let's make the name more appropriate to STG's plans to use the Atlas "as is."16 So this play on words, "Abort Sensing and Implementation System," became the designator for the only part of the Atlas created solely for the purpose of man-rating that missile. Reliability was truly designed into the "ASIS"; once this component was proven and installed, the Atlas ICBM should, it was hoped, be electromechanically transformed into the Mercury-Atlas launch vehicle.

H. Julian Allen, Ames Research Center aerodynamicist who pioneered in hypersonic wind tunnel development and provided the concept of blunt reentry bodies, which was a major contribution to ballistic missile nose-cone technology and to the Mercury capsule, briefs a delegation from the National Aeronautics and Space Council visiting Ames on August 3, 1959. Visitors are, left to right, John T. Rettaliata, Alan T. Waterman, Executive Secretary Franklyn W. Phillips, William A. M. Burden, NASA Administrator T. Keith Glennan, and Center Director Smith DeFrance.

Astronaut Donald K. Slayton defended his prospective role and STG's stance on the issue of automation when he addressed his brethren in the Society of Experimental Test Pilots on October 9. By his own admission, these were some "stubborn, frank" words:

First, I would like to establish the requirement for the pilot.... Objections to the pilot range from the engineer, who semi-seriously notes that all problems of Mercury would be tremendously simplified if we didn't have to worry about the bloody astronaut, to the military man who wonders whether a college-trained chimpanzee or the village idiot might not do as well in space as an experienced test pilot. The latter is associating Mercury with the Air Force MISS or Army Adam programs which were essentially man in a barrel approaches. The answer to the engineer is obvious and simple. If you eliminate the astronaut, you can see man has no place in space. This answer doesn't satisfy the military skeptic, however, since he is not questioning the concept of a man in space but rather what type man. I hate to hear anyone contend that present day pilots have no place in the space age and that non-pilots can perform the space mission effectively. If this were true, the aircraft driver could count himself among the dinosaurs not too many years hence.

* * *

Not only a pilot, but a highly trained experimental test pilot is desirable … as in any scientific endeavor the individual who can collect maximum valid data in minimum time under adverse circumstances is highly desirable. The one group of men highly trained and experienced in operating, observing, and analyzing airborne vehicles is the body of experimental test pilots represented here today. Selection of any one for initial space flights who is not qualified to be a member of this organization would be equivalent to selecting a new flying school graduate for the first flight on the B-70, as an example. Too much is involved and the expense is too great.17

Slayton's defense of Mercury before his professional colleagues outside NASA was echoed time and again in the next two years by NASA spokesmen. But many critics remained skeptical because it was obvious that Mercury was being designed to fly first without man. Flight controllers and electronics engineers who had specialized in ground control of supersonic interceptors and who had confidence in the reliability of remote control of automatic weapon systems were the least enthusiastic about allowing the pilots to have manual overrides. Christopher C. Kraft, Jr., the chief flight director for STG, preceded Slayton on the same program at the meeting of the experimental test pilots. He reviewed the range network to be provided and the operational plan to be used for the Mercury orbital mission. At that time, Kraft circumspectly avoided any public indication of his personal views on the role the astronaut would play, but years later he confessed his bias:

The real knowledge of Mercury lies in the change of the basic philosophy of the program. At the beginning, the capabilities of Man were not known, so the systems had to be designed to function automatically. But with the addition of Man to the loop, this philosophy changed 180 degrees since primary success of the mission depended on man backing up automatic equipment that could fail.18

In public, the managers of NASA and of Mercury, who had to request funds and justify their actions before Congress and the people, appeared as optimistic as possible and pointed out what could be achieved with successful missions. Privately, they not only had doubts, they cultivated a group of professional pessimists whose job it was to consider every conceivable malevolent contingency. John P. Mayer, Carl R. Huss, and Howard W. Tindall, Jr., first led STG's Mission Analysis Branch and set a precedent for spending ten times as much effort on planning for abnormal missions as for normal ones.19

Although not always obvious to STG, there also were differences in attitudes within the space medicine fraternity. Since mid-1958, men like Siegfried J. Gerathewohl and George R. Steinkamp had led the school of thought that believed that man was more nearly machine-rated than machines were man-rated. Conversely, the chief of the space medicine division of the Air Force's School of Aviation Medicine, Colonel Paul A. Campbell, influentially asserted his belief that "in these past two or three years the situation has suddenly changed, and the machine capability has advanced far beyond man's capability."20 Other biologists and medical college specialists also had doubts about the peculiar combination of stresses - from high to zero to high g loads - that the man in Mercury must endure. Whatever the majority medical opinion might have been, the Task Group felt itself beleaguered by bioastronautical specialists who wanted to "animal-rate" the spaceflight machines all the way from amoebas through primates before risking a man's life in orbit.

Approaches to Reliability

"Reliability" was a slippery word, connoting more than it denoted. Yet as an engineering concept it had basic utility and a recognized place in both aviation and missile technology. The quest for some means of predicting failures and thereby raising the odds toward success began modestly as a conscious effort among STG and McDonnell engineers only in mid-1959, after design and development work on major systems was well under way. Other engineering groups working in support of Project Mercury also began rather late to take special care to stimulate quality control and formal reliability programs for booster and capsule systems. Mercury would never have been undertaken in the first place if the general "state-of-the-art" had not been considered ready, but mathematical analyses of the word "reliability" both clarified its operational meaning and stirred resistance to the statistical approach to quality control.

The fifties had witnessed a remarkable growth in the application of statistical quality control to ensure the reliability of weapon systems and automatic machinery. The science of operations analysis and the art of quality management had emerged by the end of the decade as special vocations. Administrator Glennan himself, as president of Case Institute of Technology, had encouraged the development over the decade of one of the nation's foremost centers for operations research at Case.21 STG executive engineers studied an almost pedestrian example of these new methods for more scientific management of efficiency; it was one given by an automobile executive who compared the reliability of his corporation's product over 32 years before 1959:

If the parts going into the 1959 car were of the same quality level as those that went into the 1927 car, chances would be even that the current model would not run.

This does not mean that the 1927 car was no good. On the contrary, its quality was excellent for that time. But it was a relatively simple product, containing only 232 critical parts. The 1959 car has 688 such parts. The more the critical parts, the higher the quality level of each individual part must be if the end product is to be reliable.22

In view of the fact that estimates showed over 40,000 critical parts in the Atlas and 40,000 more in the capsule, the awesome scale and scope of a reliability program for Mercury made it difficult to decide where to begin.

To organize engineering design information and data on component performance, someone had first to classify, name, or define the "critical parts." To create interrelated systems and to analyze them as separate entities at the same time was difficult. The Space Task Group and McDonnell worked on creation at the expense of analysis through 1959. Gradually NASA Headquarters and Air Force systems engineers steered attention to certain "semantic" problems in the primitive concepts being used for reliability analyses. For instance, what constitutes a "system"? How should one define "failure"? What indices or coefficients best "measure" overall system performance from subsystem data?23

These and other features of reliability prediction were so distasteful to creative engineers that many seriously questioned the validity and even the reliability of reliability predictions. "Reliability engineering," admitted one apologist in this field, "may seem to be more mysticism and black art than it is down-to-earth engineering. In particular, many engineers look on reliability prediction as a kind of space-age astrology in which failure rate tables have been substituted for the zodiac."24 Around STG this skeptical attitude was fairly representative. But at NASA Headquarters, Richard E. Horner, newly arrived in June 1959 as Associate Administrator and third man in command, had brought in a small staff of mathematicians and statisticians. It was led by Nicholas E. Golovin, who transferred from the Air Force to NASA some of the mathematical techniques lending quantitative support to demands for qualitative assurance. Theory-in-Washington versus practice-at-Langley were in conflict for a year until the nature of "reliability" for pilot safety on the one hand and for mission success on the other became more clearly understood by both parties. The pressure exerted by Golovin and NASA Headquarters to get the Task Group and McDonnell to change its approach to raising reliability levels became a significant feature in redesign and reliability testing during 1960.25

Scientists, statisticians, and actuaries, working with large populations of entities or events, had long been able to achieve excellent predicitions by defining reliability as probability, but in so doing they sacrificed any claim to know what would happen in a unique instance. Engineers and managers responsible for a specific mission or project tended to ridicule probability theory and to call it invidiously "the numbers game." Being limited to a small set of events and forced by time to overlap design, development, test, and operations phases, they could not accept the statistical viewpoint. They demanded that reliability be redefined as an ability. The senior statistician at Space Technology Laboratories for the Atlas weapon system, Harry Powell, recognized and elaborated on this distinction while his colleagues became involved with man-rating the Atlas. His remarks indicated the STL and Convair/Astronautics faced the same divergence of opinion that NASA Headquarters and STG confronted:

If reliability is to be truly understood and controlled, then it must be thought of as a device a physical property which behaves in accordance with certain physical laws. In order to insure that a device will have these physical properties it is necessary to consider it first as a design parameter. In other words, reliability is a property of the equipment which must be designed into the equipment by the engineers. Reliability cannot be tested into a device and it cannot be inspected into a device; it can only be achieved if it is first designed into a device. Most design engineers are acutely aware that they are under several obligations - to meet schedules, to design their equipment with certain space and weight limitations, and to create a black box (a subsystem) which will give certain outputs when certain inputs are fed into it. It is imperative that they also be aware of their obligation to design a device which will in fact perform its required function under operation conditions whenever it is called upon to do so.26

There is a rule in probability theory that the reliability of a system is exactly equal to the product of the reliability of each of its subsystems in series. The obvious way to obviate untrustworthy black boxes was to connect two black boxes in parallel to perform the same function. In other words, redundancy was the technique most often used to ensure reliability.

After the cancellation of Mercury-Jupiter, Kuettner and others at ABMA set about a serious effort to develop a parachute system to recover the Redstone booster. They also began to concentrate on the simplifications necessary for the sake of reliability to custom-build a man-rated Redstone. Starting with the advanced, elongated version of the rocket, which had been renamed the "Jupiter-C" in 1956 for the Army's ablation research on reentry test vehicles, Kuettner called upon the expertise of all who could spare time from the Saturn program to help decide how to man-rate their stock. The fundamental change made to the Jupiter-C airframe was the elimination of its staging capability. Other modifications stripped it of its more sophisticated components while permitting it to retain greater performance characteristics than the original single-stage Redstone.27

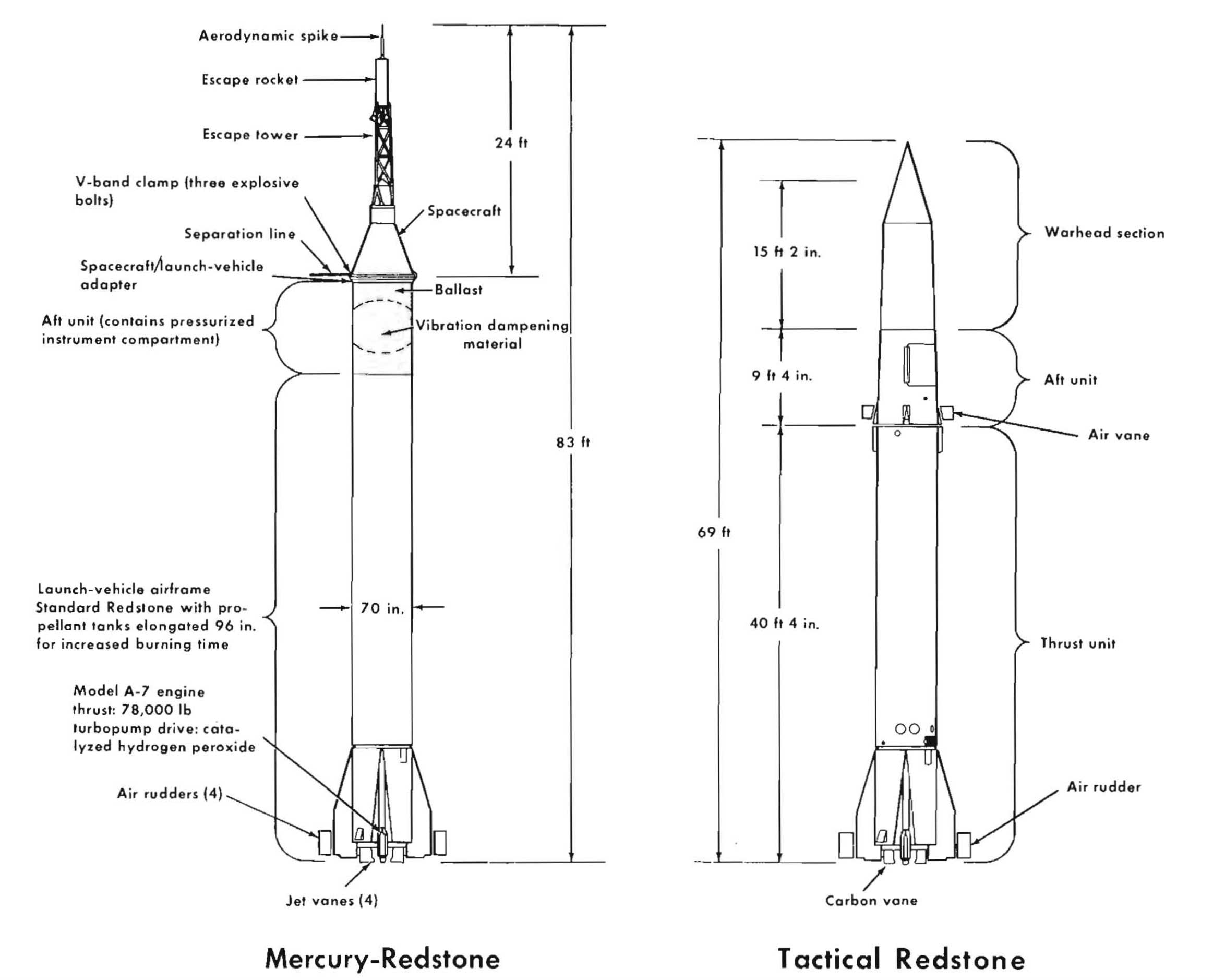

The designers of the Redstone and Jupiter missile systems proposed an extensive list of basic modifications to adapt the vehicle to the Mercury capsule. The elongated fuel tanks of the Jupiter-C had to be retained for 20 extra seconds of engine burning time, especially since they decided to revert to alcohol for fuel rather than use the more powerful but more toxic hydyne that fueled the Jupiter-C. Another high-pressure nitrogen tank to pressurize the larger fuel tank and an auxiliary hydrogen peroxide fuel tank to power the engine turbopump also had to be added. To increase the reliability of the advanced Redstone, they had to simplify other parts of the Jupiter-C system. Instead of the sophisticated autopilot called ST-80, one of the first inertial guidance systems (the LEV-3 ) was reinstalled as the guidance mechanism. The after unit of the payload on the old Redstone, which had contained a pressurized instrument compartment, became the permanent forebody of the main tank assembly, there being no need to provide terminal guidance for the new payload. A spacecraft adapter ring likewise had to be designed to simplify interface coordination and to ensure clean separation between capsule and booster. At the other end of the launch vehicle it was necessary to use the most recent engine model, the A-7, to avoid a possible shortage of spare parts. Hans G. Paul and William E. Davidson, ABMA propulsion engineers, took the basic responsibility for "manrating" this engine.28

Although STG engineers bought the Redstone in the first place because it was considered an "off-the-shelf" rocket, they gradually learned through Hammack's liaison with Butler that the Mercury-Redstone was in danger of being modified in about 800 particulars, enough to vitiate the record of reliability established by the earlier Redstones and Jupiter-Cs. Too much redesign also meant reopening the Pandora's box of engineering "trade-offs," the compromises between overdesign and underdesign. Von Braun's team tended in the former direction; Gilruth's in the latter. To use Kuettner's distinction, ABMA wanted "positive redundancy" to ensure aborts whenever required, whereas STG wanted more "negative redundancy" to avoid aborts unless absolutely essential.29 This distinction was the crux of the dispute and the essence of the distinction between "pilot safety" and "mission success."

On July 22, 1959, STG engineers received a group of reliability experts from von Braun's Development Operations Division at Huntsville. Three decades of rocket experience had ingrained strongly held views among the 100 or so leaders of this organization about how to ensure successful missions. The ABMA representatives told STG that they did not play the "numbers game" but attacked reliability from an exhaustive engineering test viewpoint. Their experience had proved the adequacy of their own reliability program, carried out by a separate working group on a level with other engineering groups and staffed by persons from all departments in the Development Operations Division of ABMA. In conference with design engineers, ABMA reliability experts normally set up test specifications and environmental requirements for proving equipment compliance. STG felt sympathetic to this approach to reliability, but systems analysts at NASA Headquarters did not.

As for the prime contractor's reliability program, in the first major textbook studied by the astronauts, McDonnell's "Project Mercury Indoctrination" manual, distributed in May 1959, the pilots read these reassuring words:

The problem of attaining a high degree of reliability for Project Mercury has received more attention than has any other previous missile or aircraft system. Reliability has been a primary design parameter since the inception of the project.30

Accompanying reliability diagrams showed over 60 separate redundancies designed into the various capsule systems, allowing alternate pilot actions in the event of equipment malfunctions during an orbital mission.

McDonnell specified three salient features of its reliability program in this preliminary indoctrination manual. First, by making reliability a design requirement and by allowing no more than a permissible number of failures before redesign and retesting were required, reliability was made a conscious goal from the beginning of manufacture. Second, five separate procedures were to implement the development program: evaluations, stress analyses, design reviews, failure reporting, and failure analysis. Third, reliability would be demonstrated finally by both qualification and reliability testing.

These assurances did not seem adequate; STG, as well as NASA-Washington, requested McDonnell to clarify its reliability policy in more detail and to hold a new symposium in mid-August to prove the claim that "reliability is everybody's business at McDonnell." McDonnell responded by changing its "design objective" approach to what may be called a "development objective" approach. The new program, drawn by Walter A. Harman and Eugene A. Kunznick, explicitly set forth mean times to failure and added more exhaustive demonstrations, or "life tests," for certain critical components. More fundamental assumptions were made explicit, such as: "the reliability of the crew is one (1.0)," and "the probability of a catastrophic explosion of the booster, of any of the rockets, of the reaction control system, or of the environmental control system is negligible."31 McDonnell's presentation at this symposium stressed new quality control procedures and effectively satisfied STG for the moment. Golovin and his NASA Headquarters statisticians were pleased to note refinement in sophistication toward reliability prediction in the capsule contractor's figures for the ultimate 28-hour Mercury mission. At the August 1959 reliability symposium, McDonnell assigned impressively high percentage figures as reliability goals for both mission and safety success:

| Mission | Safety | |

|---|---|---|

| Boost | .7917 | .9963 |

| Orbit | .9890 | .9999 |

| Retrograde | .9946 | .9946 |

| Reentry | .9992 | .9992 |

| Overall | .7781 | .9914 |

To John C. French, who began the first reliability studies for Gilruth's group, this kind of table represented the "numbers game," mere gambling odds that might deceive the naive into believing that if not the fourth, then the third, decimal place was significant. French was an experienced systems engineer who recognized that numbers like these did mean something: obviously the authors felt the weakest link in the chain of events necessary to achieve mission success was the launch vehicle. McDonnell believed the safety of the astronaut would be ensured by the escape system, but the coefficient ".7917" diluted the confidence in overall mission success to ".7781." McDonnell and STG agreed that the onus was on the Atlas to prove its safety and reliability as a booster for the Mercury mission.

That point was not disputed by the men responsible for the Atlas. They professed even less confidence in their product for this purpose than the capsule contractor had. Not until November 13, 1959, did representatives of the Air Force Ballistic Missile Division and Space Technology Laboratories visit Langley to present in detail their case for a thoroughgoing plan to man-rate the Atlas as a Mercury booster. Harry Powell had prepared a carefully qualified chart that estimated that the reliability of the Mercury booster would reach approximately 75 percent only in mid-1961, and the first upbend (at about 86 percent) on that curve was to occur another year later.32 Such pessimism might have been overwhelming to STG except that no abort-sensing system was yet computed as a factor in this extrapolation. Also STG and STL agreed never to entertain the idea of "random failure" as a viable explanation.

Because aircraft designers and missile experts held different opinions about which systems should be duplicated, redundancy itself was often a subject of dispute. Passenger aircraft were provided with many redundant features, including multiple engines and automatic, semi-automatic, and manual control systems, so that commercial flight safety had been made practically perfect. But in the military missile programs of 1959, redundancy to ensure mission success had been relegated to the duplication of the complete missile, "by making and launching enough to be sure that the required number will reach each target."33 In the age of "overkill," one out of four, for instance, might be considered quite sufficient to accomplish the destructive mission of the ICBM. Both McDonnell and the Task Group placed more faith in quality control procedures and in redundant system development than in mathematical models for reliability prediction during design.

In the course of further symposia and conferences during the autumn, the Space Task Group, working with military systems analysts and industrial quality controllers, learned more than it taught about improving reliability programs. Abe Silverstein, whose Headquarters office was retitled Space Flight Programs (instead of Development) at the end of the year, was especially eager to see STG set up its own reliability program, with procedures for closer monitoring of subcontracts.34

But before STG could presume to teach, it had to learn much more about the mechanics of the Redstone and the Atlas. Mathews had his own mathematicians check the case histories for failures of every Redstone, Jupiter, and Atlas that had ever been launched. A statistical population of over 60 Redstone and about 30 Atlas launches yielded clinical diagnoses for generalizing about the most likely ways these boosters might fail. Gerald W. Brewer, Jack Cohen, and Stanley H. Cohn collected much of this work for STG, and then Mathews, Brandner of ABMA, White of STL, and others formulated some ground rules for the development of the two abort-sensing systems.

All the investigators were pleasantly surprised to find relatively few catastrophic conditions among the failures. Their biggest problem was not what to look for or when to allow the escape rocket to blast away but rather how to avoid "nuisance aborts." Such unnecessary or premature escapes would arise from overemphasis on pilot safety or "positive redundancy" at the expense of mission success. Long arguments ensued over several questions: How simple is safe? How redundant can you get and still have simplicity? How do you design a fail-safe abort-sensing system without overdesigning its sensitivity to situations less than catastrophic?35

Without trying to define every term, Mathews and his associates agreed that only imminent catastrophic failures were to be sensed, that reliability should be biased in favor of pilot protection, and that all signals from abort sensing should be displayed in the spacecraft. Application of these ground rules to the Redstone led to development of an automatic abort-sensing system (AASS) that sensed "downstream" or fairly gross parameters, each of which was representative of many different types of failures. Merely "critical," as opposed to "catastrophic," situations were not allowed to trigger the escape system automatically. Such merely "critical" situations as partial loss of thrust, a fire in the capsule, deviation from flight path, or loss of tank pressure might possibly be corrected or tolerated. But catastrophic situations were defined as existing where there were no seconds of time for intelligent decisions, corrective actions, or manual abort. The abort system for the Mercury-Redstone sensed and was activated by such typical catastrophic situations as excessive attitude deviations or turning rates (leading to high angles of attack during high dynamic pressures and resulting in a structural breakup), as sudden loss of tank or bulkhead differential pressure in pressure-stabilized structures, as loss of electrical power in the control and instrument system, and as loss of thrust immediately after liftoff.36

If any of these situations should arise, the automatic abort-sensing system was supposed to initiate an explosively rapid sequence of events. First, the engine of the Redstone would cut off (except during the initial moments over the launch site). Then the capsule would separate from the booster. And this would be followed by the ignition of the escape rocket, with acceleration up and away from the booster, and finally by the normal sequencing of events in the recovery phase of the launch profile.

During August, September, and October, the Task Group improved its understanding of the interrelated parts and procedures being developed for Mercury. New definitions were formulated in hardware and words. Some old worries - the heatshield, for instance - were abandoned as newer concerns replaced them. The success of Big Joe and the promise of Little Joe shots promoted confidence and sustained enthusiasm. At the end of this period optimistic forecasts were the rule, not only for booster readiness but also for firm operational schedules. The first Mercury-Redstone and Mercury-Atlas qualification flight tests were scheduled for launchings in May 1960. Even the final goal of Project Mercury, the achievement of manned orbital flight around Earth, still appeared possible by March 1961.37

But as autumn blended into winter in 1959, optimism cooled along with the weather. The job of keeping snow clear of its own drive was difficult enough, but heavier equipment than that possessed by the Task Group was necessary to plow aside the drifts that sometimes covered the streets of interagency cooperation. In particular, the Mercury-Redstone schedule began to look progressively more snowbound in the early winter of 1959, largely because the capsule and the Atlas commanded primary attention.

At the end of August, Gilruth had proposed to Major General John B. Medaris, commanding ABMA, that the first attempt at a Mercury-Redstone launch from the Cape be set for February 1, 1960. This proposal represented a slippage of about four months since February 1959, when the initial understanding between ABMA and STG had been reached. But the prospects for rapid accomplishments in the next six months were brighter at Langley than at Huntsville, St. Louis, or the Cape. Plans to use eight Mercury-Redstones for ballistic training flights between February and October 1960 were still in effect, and STG also hoped to complete six manned Redstone flights by March 1961 before launching the first of the manned Mercury-Atlas configurations. Such optimism was not entirely the result of youthful naivete or of underestimates of complexity. In large part, target dates were set deliberately at the nearest edge of possible completion periods to combat Parkinson's Law regarding bureaucratic administration, that work expands to fill the time allotted for its completion.38

Much of the fault for Redstone slippages must revert to STG for having canceled the Mercury-Jupiter series rather precipitously, thereby unceremoniously relegating the 4000 members of von Braun's division at Huntsville almost to "task element" status as far as Mercury was concerned. Although the Jupiter program per se was being phased out at ABMA, its sires, who sparked the entire Army Ordnance team, were sensitive to criticism of their strange love for space travel.39 STG engineers should not have been surprised that the cancellation of the Mercury-Jupiter series would cause a reaction in Huntsville that would reverberate to the Cape and through Washington.40

Although NASA Headquarters had carefully coordinated STG's recommendation in this matter, many other factors contributed to the change in the Mercury program management plans that forecast the slip of MR-1 past MA-1 on the flight test schedule. There were at least three technical reasons for the Mercury-Redstone slippages as well as several other, perhaps more important, psychological and policy-planning reasons for this change in the "progressive buildup of tests" principle.

Foremost among all causes of delay was the fact that the pacing item, McDonnell's production model of the Mercury capsule, took longer to build than anyone supposed it would.4l Because systems integration within the spacecraft was lagging by several months, every other area would be delayed also to some degree. Secondly, the design and development of the abort-sensing systems for the Redstone and Atlas were attacked separately and not cross-fertilized. The basic dispute over safety versus success, or positive versus negative redundancy, could be settled only with actual flight test experience.

A third technical reason for the fact that the Redstone team, with its ready and waiting boosters, failed to lead off the series of qualification flight tests was related to the Teutonic approach to reliability. Long years of experience with rockets, together perhaps with some native cultural concern for meticulous craftsmanship, gave the von Braun group high confidence that most so-called "reliability" problems could be obviated by hard work, more flight tests, and intensive engineering attention to every detail. Elaborate operational checkouts were to be made at Huntsville and the Cape. STG agreed to these procedures in August, but by November time was clearly in contention between Huntsville and Langley. The Task Group wanted to launch its first three Redstones for Mercury during May and June 1960, but if this were possible, it was hardly advisable from ABMA's point of view.42

By then, however, this could be considered a family dispute among stepbrothers within NASA. On October 21, 1959, President Eisenhower announced his decision, pending congressional approval, to transfer the von Braun group and the Saturn project from ABMA to NASA. If this decision solved a morale problem among members of the Development Operations Division at ABMA, it undoubtedly complicated certain institutional and political problems. Jockeying for position probably intensified rather than abated, as plans for the future use of the Saturn launch vehicle overshadowed Mercury for the moment. Another five months were required to complete a transfer plan, and eight months would elapse before the official transfer was completed on July 1, 1960.43

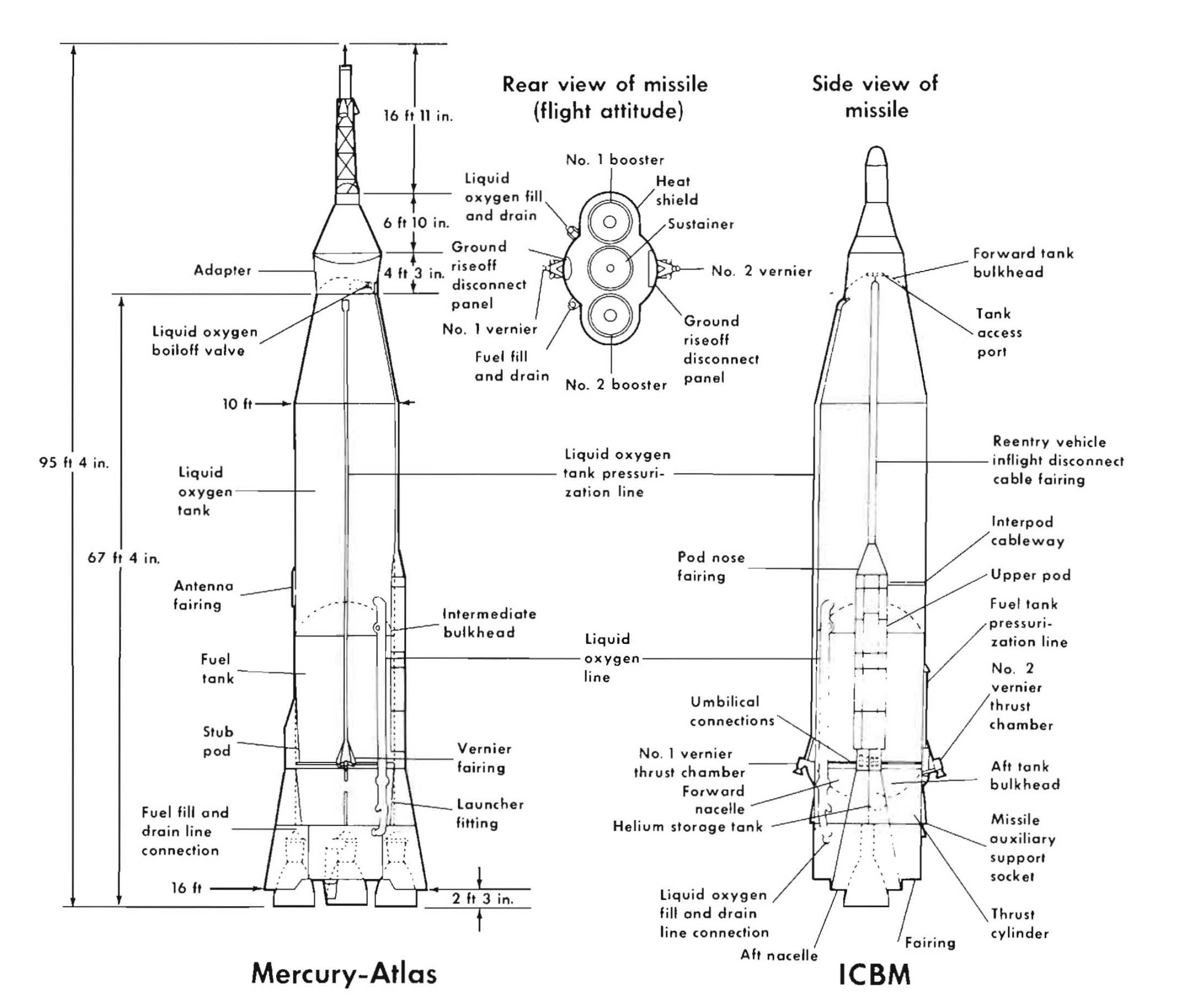

Although the plans for the escape of a pilot from a malfunctioning Redstone were complex, plans for a similar emergency detection system on the Atlas were several times more complicated. Three engines, rather than one, with an overall range and thrust capability well over three times greater, and with guidance, gimbaling, and structural separation mechanisms far more complex than those to be used on the Redstone - these were some of the factors that put the problem of man-rating the Atlas on a higher plane of difficulty. The Mercury capsule escape system was, of course, the same for both boosters, but the emergency detection systems had to be tailored to the differences between the launching vehicles. The single-stage Redstone was a piece of battlefield artillery that could stand on its own four fins, for example, whereas the fragile "gas-bag" Atlas would crumple if not pressurized. And in flight, the Atlas' outboard engines must stage properly and drop away from the central sustainer engine before the escape tower could be jettisoned.

While Charles Wilson and his crew at Convair in San Diego worked out the detailed design and hardware for ASIS, Richard White led Space Technology Laboratories through more detailed analytical studies and simulation tests at El Segundo. Their concurrent efforts ensured that the airborne emergency detection system for the Mercury-Atlas evolved, as Powell insisted it must, with the steadfast goal of reliability. Inspection and test programs were inaugurated separately by Hohmann, beginning in October, but reliability was designed into the ASIS black box from May onward. Wilson and White soon discovered that their biggest problem concerned the prevention of recontact between booster and capsule after separation. Alan B. Kehlet and Bruce G. Jackson of STG had the primary responsibility to determine the proper thrust offset of the escape rocket and to ensure against recontact, but "Monte Carlo" probability analyses were done by both Convair and the Space Task Group.44

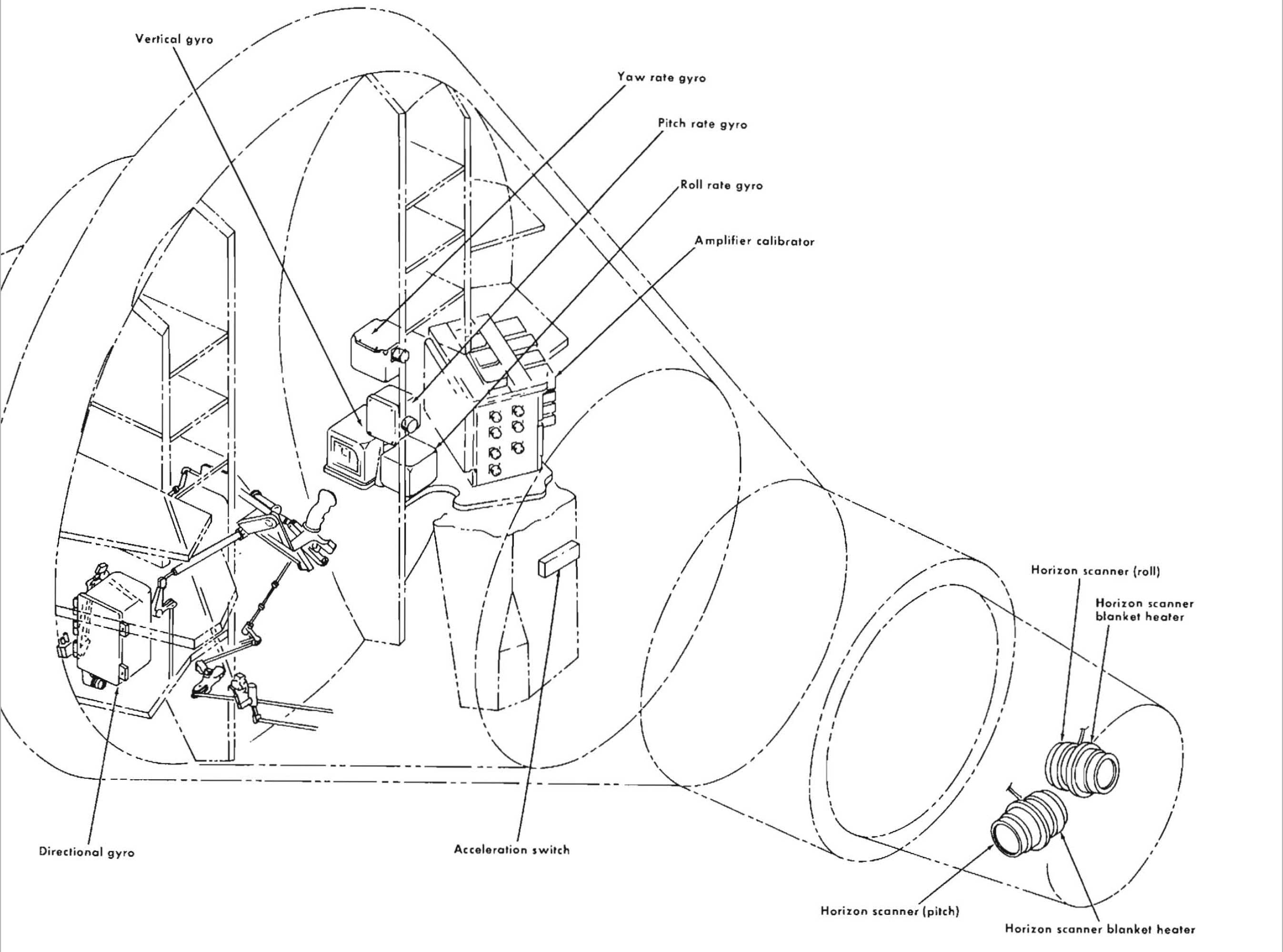

In addition to the ASIS, the Atlas D had to be modified in a number of other ways before it could carry a man. Because the Mercury-Atlas configuration was taller by approximately 20 feet than the Atlas D weapon system, the rate gyro package for the autopilot had to be installed 20 feet higher on the airframe, so it would sense more precisely the rate of change of booster attitude during launch. The Atlas would not need posigrade rockets to assist separation because the Mercury capsule would embody its own posigrade rockets inside its retrorocket package. Because the capsule's posigrade rockets could conceivably burn through the thin skin of the liquid-oxygen dome, a fiber-glass shield covering the entire dome was attached to the mating ring. The two small vernier rocket engines, which on the ICBM had thrust on after sustainer engine cutoff, or "SECO," for last-minute trajectory corrections, were regoverned to delete the "vernier solo" phase of operation, thus saving more weight and complexity. In addition to the use of older, more reliable types of valves and special lightweight telemetry, only one other major booster modification was considered at first. The man-rated Atlas D would use the so-called "wet start" instead of the newer, faster "dry start" method of ignition. A water pulse sent ahead of the fuel into the combustion chambers would effect slower and smoother initial thrust buildup, minimizing structural stress on the engine before liftoff. This change saved approximately 60 pounds, by enabling the use of a thinner skin gauge in the Atlas airframe. But the "thin-skinned" Atlas soon proved to be too thin-skinned, and the weight saved was lost again in 1961, when a thicker skin was found to be essential in the conical tank section just under the capsule. The longer, lighter spacecraft payload proved a cause of additional dynamic loads and buffeting problems, calling for more strength in the Atlas forebody.45

After additional study of the idiosyncracies of the Atlas missile, Mathews, Wilson of Convair, and White decided on the parameters most in need of monitoring for abort indications:

- the liquid oxygen tank pressure,

- the differential pressure across the intermediate bulkhead,

- the booster attitude rates about all three axes,

- rocket engine injector manifold pressures,

- sustainer hydraulic pressure, and

- primary electrical power.

Dual sensors gauging each of these catastrophic possibilities were fairly easily developed. If any one of these conditions should arise or any system should fail, the ASIS would by itself initiate the explosive escape sequence. But any one of four men with their fingers poised over pushbuttons also could abort the mission: the test conductor, the flight director in the control center, the range safety officer, or the astronaut with his left thumb would be able to decide if and when the escape rocket should be ignited. But these manual abort capabilities were only supplements, with built-in time delays, to the automatic abort sensing and implementation system. During the portion of the flight powered by the Atlas, human judgment was to be secondary to a transistorized watchdog autopilot. Their moral obligation to pilot safety made the Atlas redesigners reduce man-control to this minimum. Culbertson later explained, "While it was true that mission success provided pilot safety, provision for pilot safety did not always improve the probability of mission success"46

One of the most important analytical tasks in man-rating the Atlas was the careful and continuous study of the mathematical guidance equations for the launch phase of all the missions. Three men at Space Technology Laboratories shared this responsibility, C. L. Pittman, Robert M. Page, and Duncan McPherson. While Convair was learning that it cost approximately 40 percent more to build a man-rated Mercury-Atlas than a missile system, STL's mathematicians and systems engineers, like Hohmann and Letsch, were working out their differences on how to control quality and augment reliability. By the end of 1959, Hohmann had sold his plans for pilot safety. They were based on applying supercharged aircraft production techniques to industrial practices for military missile production. To live with the Atlas required no less and eventually much more.47

Critical Components of the Capsule

Basic as the boosters were for successful manned space flight, they were not the only machines that had to be certified for safety before a man's life could be entrusted to them. The capsule with all its systems and subsystems, designed to operate automatically on unmanned test flights at first, would also have to have reliable provisions for operation with a normal, or even with an incapacitated or unconscious, man aboard. Man-rating the spacecraft, therefore, involved the paradoxical process of dehumanizing it first for rehumanizing later.

When the seven Mercury astronauts first visited the McDonnell Aircraft Corporation laboratories and factory, for three days in May 1959, each was handed an indoctrination manual and given opportunities to inspect the mockup capsule and to review the requests for alterations made by the Mockup Review Board in March. Immediately they expressed some uneasiness about the poor visibility afforded by the two remotely placed portholes and about the difficulty of climbing out the bottleneck top of the capsule.48 So, based on these and numerous other criticisms expressed by the men for whom these machines were being built, redesign studies were begun.

Just as Maxime Faget was the chief NACA-NASA designer of the capsule configuration and mission concept, so John F. Yardley, his closest counterpart in the McDonnell organization, was the chief developer of the Mercury capsule. Neither Faget nor Yardley was the nominal leader of the vast team within which each worked, but both animated the technical talents of their colleagues, from design through the final development stages of the Mercury hardware. John Yardley held a master's degree in applied mechanics, had worked for McDonnell since 1946 as a stress analyst, strength engineer, and project leader, and he was exceptionally talented in his capacity for work and for synthesizing technical knowledge. By telephone, teletype, and face to face, Faget and Yardley consulted each other about the multitude of detailed design and development decisions involved in production throughout 1959. But their bilateral agreements were restricted to details. Larger decisions regarding the development of systems or interaction between subsystems were reserved for the 17 different working groups in STG and the 10 or so at McDonnell. James Chamberlin instigated this capsule coordination system and gradually replaced Faget in relations with Yardley during the next year.49

In 1959 the McDonnell Aircraft Corporation became the 100th-largest industrial company in the United States, employing approximately 24,000 people to produce goods (primarily the F4H-1 Phantom twin-jet fighter for the Navy) and services (mainly computer time, electronic equipment, and systems engineering) valued at $436 million. Within this corporate context, the contract with NASA for about $20 million to manufacture 12 or more spacecraft, requiring only 300 or 400 workers and representing less than five percent of McDonnell's annual sales volume, appeared rather minuscule. The president of the corporation, J. S. McDonnell, in September 1959 wrote for his twentieth annual report to stockholders that "there is no need to stampede away from the aircraft business."50

When the prime contract for Mercury was awarded to McDonnell, the Corporation's vice-president for project management, David S. Lewis, assigned Logan T. MacMillan, a tall, tactful test pilot and mechanical engineer with a winning manner, to be companywide project manager with authority to mobilize the resources of the Corporation for the new venture. MacMillan, of the same age and rank as Faget, soon found it difficult to reconcile McDonnell's development and production phases with NASA's concurrent research and test phases. Time, cost, and quality control were interdependent, and now the astronauts and STG had called for major design changes in the window size and placement, the side entrance-exit hatch, the instrument panel, and switch accessibility. To his top management, MacMillan reported on July 18, 1959:

The Space Task Group is a rather loosely knit organization of former Research Engineers. The Coordination Office is an attempt to channel and control information and requirements against MAC more closely and is a good move. It is clear, however, regardless of whether or not it succeeds, the NASA philosophy of investigation and approval of the smallest technical details will continue, and request for changes will also continue. We will continue to handle this by being responsive to requests for studies and recommendations and to be as flexible as we possibly can to incorporate changes. It is imperative that we continue to improve our capability to make these studies promptly, submit change proposals to cover the increased work as soon as possible, and evaluate the effect of changes on delivery schedules rapidly.51

A month later MacMillan complained by teletype message directly to Paul E. Purser that coordination meetings were being held too frequently for effective action on items from preceding meetings. He suggested that later meetings be scheduled "for one month from time minutes are received at MAC." But the pace did not slow significantly; the finish line simply moved farther away.

MacMillan and Yardley, together with Edward M. Flesh and William Dubusker, two older, more experienced production engineers, supervised the bulk of the load for McDonnell in tooling up, making jigs and fixtures, and organizing their craftsmen and procedures for production. Kendall Perkins, McDonnell's vice-president for engineering, had deliberately assigned Yardley and Flesh, combining youthful enthusiasm and experienced caution, to start the manufacture - literally the handmaking - of the first spaceframe. The subsequent design and technical development at McDonnell was carried out under their direction.52

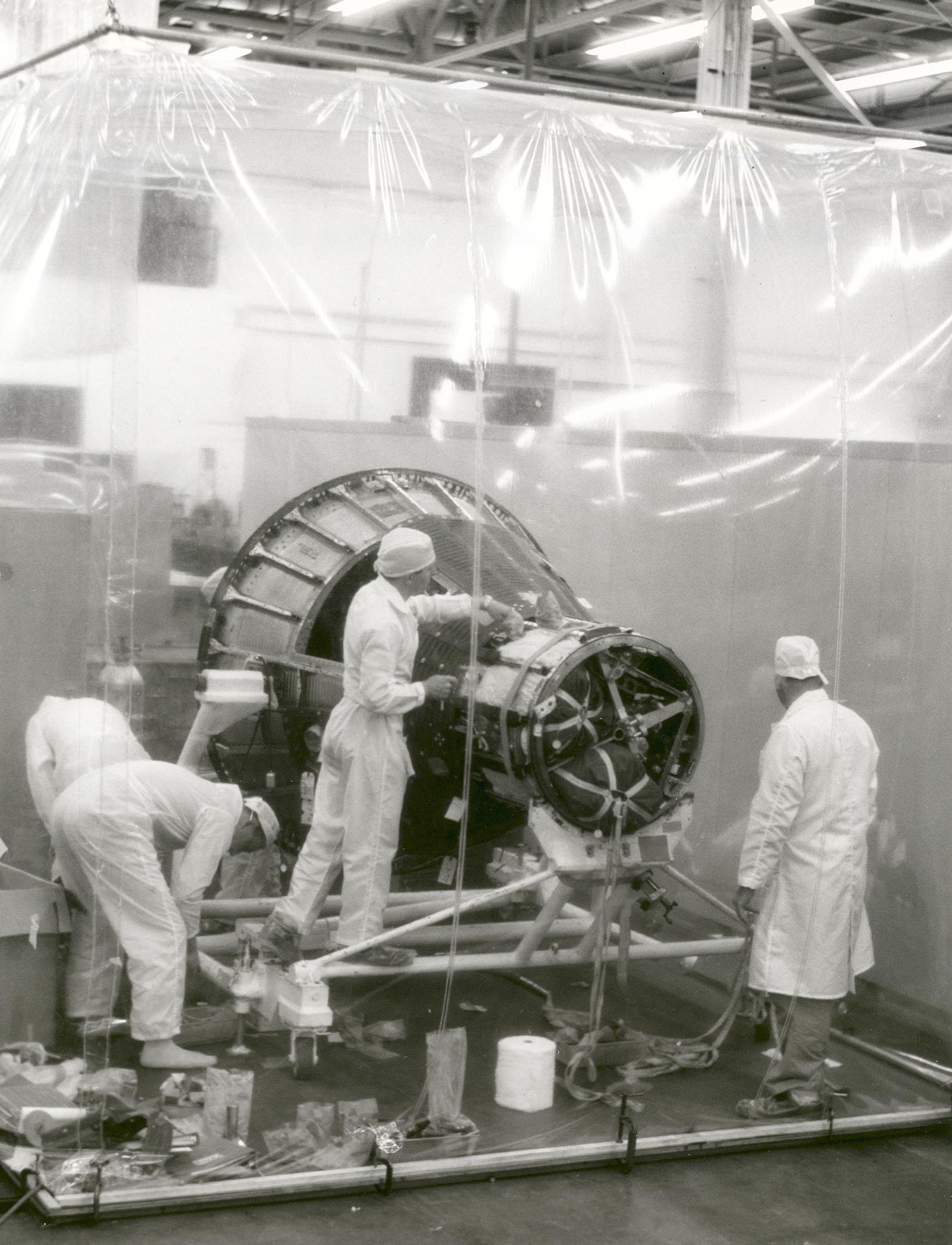

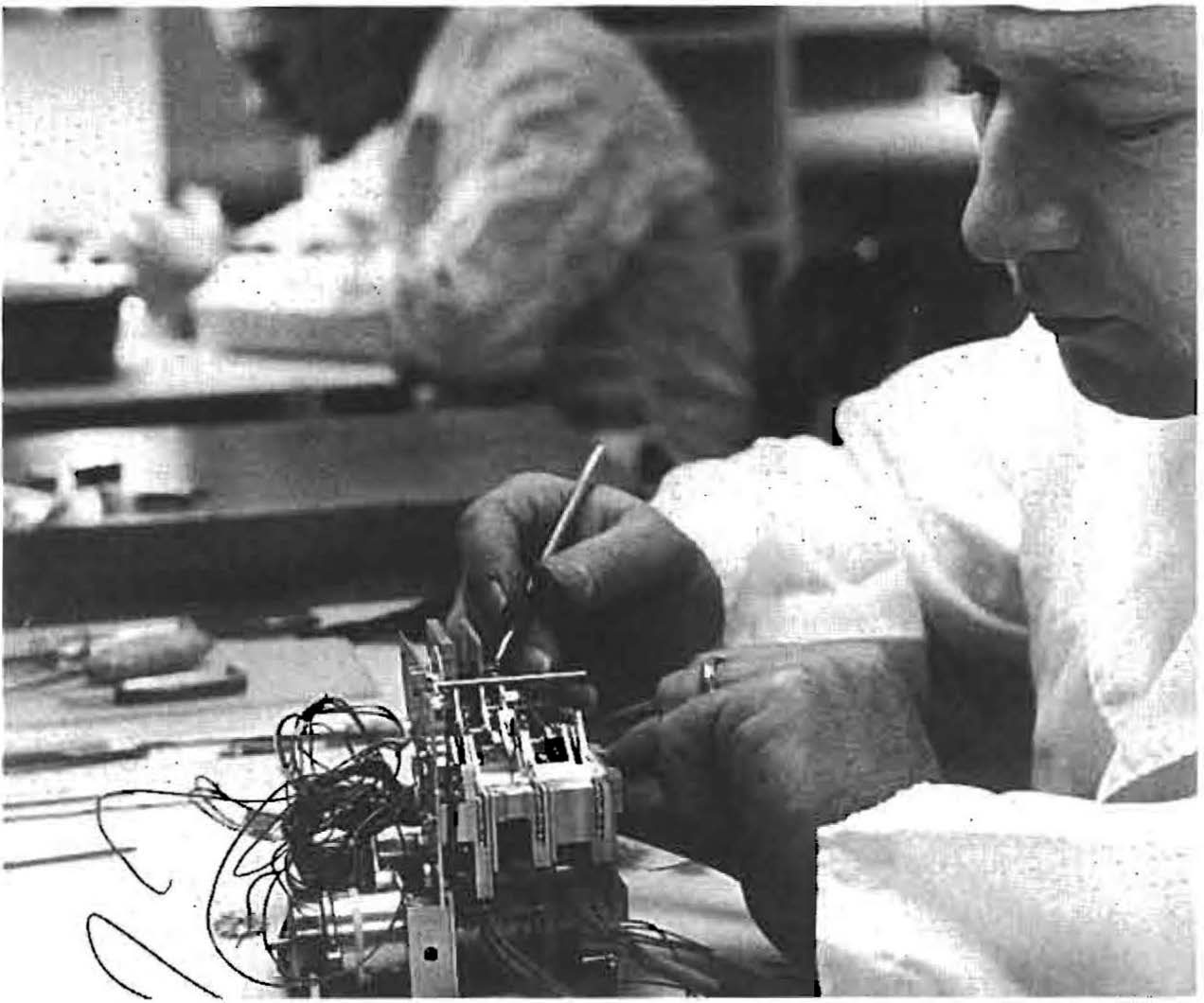

White-room manufacturing stand ards typified the revolution in upgrading of precision and reliability in manufacturing and checkout techniques. At the McDonnell plant,white-room conditions prevail as fabrication proceeds on a spacecraft.

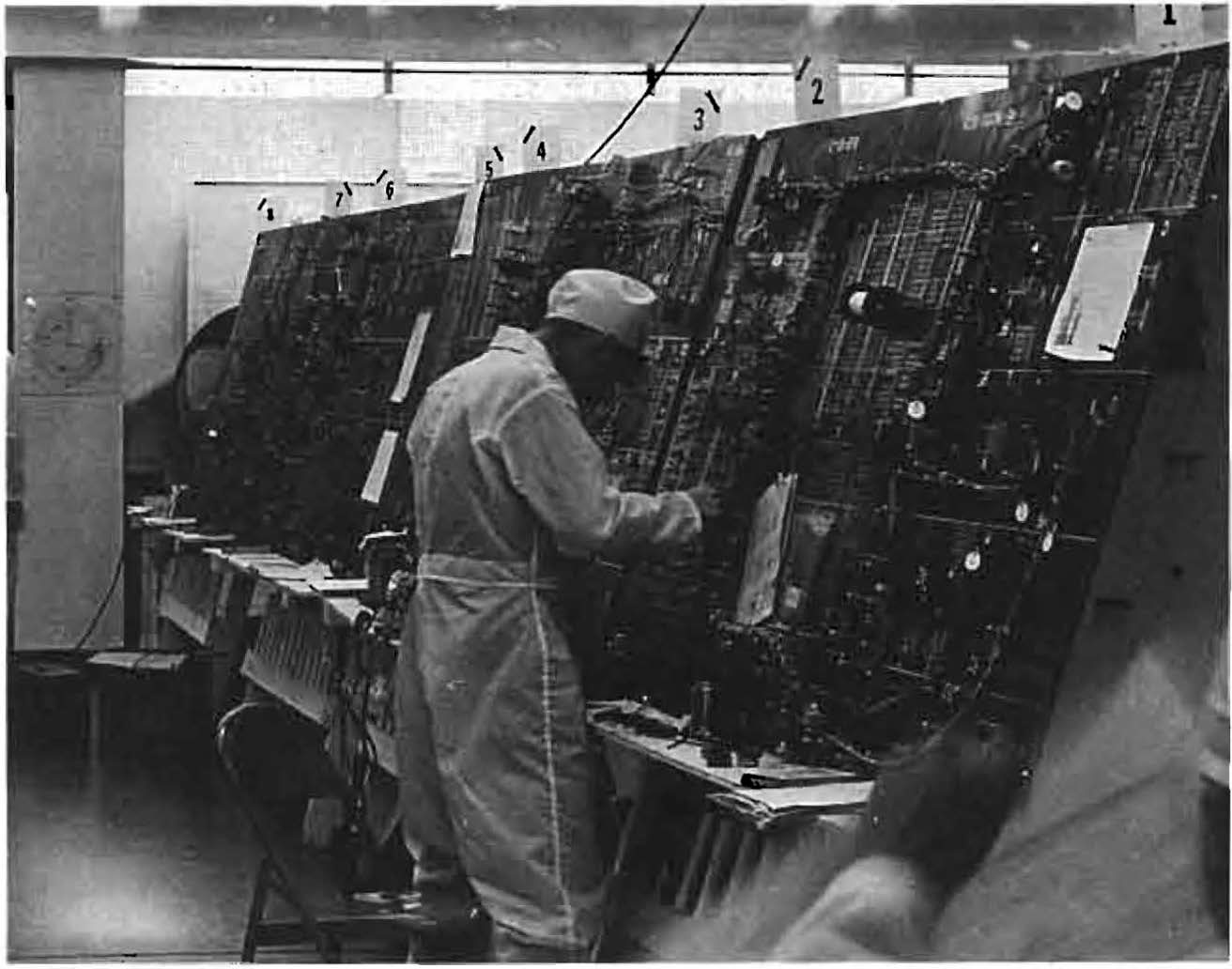

Part of a spacecraft's seven miles of wire is installed on a breadboard.

A technician assembles a compact spacecraft clock.

By July 1959, Dubusker, the tooling superintendent, had completed McDonnell's first surgically clean "white room" for the later manufacturing phases, had taken on the job of manufacturing manager for Mercury, and had moved some 200 workmen onto the new production lines. Learning to fusion-weld titanium .010-inch thin in an encapsulated argon atmosphere was his first challenge and proudest accomplishment. But before the year was over, Dubusker had to contend with retooling for other unusual materials, with rising requirements for cleanliness, with stricter demands for machined tolerances, and with higher standards for quality control.

Flesh, the engineering manager, and Dubusker drew on all of McDonnell's experience with shingled-skin structures around jet afterburners for heat protection. Their machinists had previously worked with the patented metal, René 41, a nickel-base steel alloy purchasable only from General Electric, but arc-jet tests of the afterbody shingles on the outer shell of the capsule showed a need for some ingenious new fabricating techniques.53

While Yardley and Flesh concentrated on developing the most critical components for the Mercury capsule, two other McDonnell employees began to play significant roles in man-rating this machinery. The company was fortunate to have its own so-called "astronaut" in the person of Gilbert B. North, another test-pilot engineer but one with a unique relationship for the NASA contract. He was always being confused with his identical twin brother, Warren J. North, who served Silverstein and George M. Low in Washington as NASA Headquarters participant and monitor in astronaut training. Gilbert North served McDonnell as chief human guinea pig in the St. Louis ground tests. Warren and "Bert" North actively promoted the incorporation of test-pilot concerns in the Mercury program from two standpoints outside STG.

Most of the astronauts and test pilots, including the North twins, instinctively resented the "interference" of psychologists and psychiatrists in Project Mercury. Willing to wager their careers and perhaps their necks on the automatic systems of the capsule and booster, the pilots preferred to study the reliability of the machines and to assume themselves adaptable and self-reliant in any situation. They were thus unprepared to discover that psychologists would be among their strongest allies in gaining a more active role for man during Mercury missions. Throughout 1959, arguments over the necessity for the three-axis handcontroller, as opposed to the more traditional two-axis stick and one-axis pedal control system, demonstrated these pilots' confidence in themselves. Distrusting what they regarded as tender-minded psychology and psychiatry, the astronauts-in-training studied hard to become more tough-minded electromechanical engineers. And indeed their first complaints regarding spacecraft design resulted in changes adopted formally during September for later models of the capsule.54

John Yardley fortunately was not quite so tough-minded and recognized early an imbalance in detail design considerations. He insisted on having the cross-fertilization of parallel human engineering studies. McDonnell hired in February a "human engineering" expert, Edward R. Jones, to conduct studies of pilot tasks and to analyze the various ways in which the man might fail his machines. Proposing straightaway a thorough training regimen for the astronauts in procedures simulators, Jones went on to program a statistical computation of the human-factors implications of failures in the automatic systems in the Mercury capsule. By November 1959, Yardley and Jones together had convinced a majority of McDonnell engineers that man should more often be in the automatic loop than out of it.55

Part of the problem faced by Jones, Yardley, and the astronauts in regard to human factors and the "inhuman" automatic control systems was the initial position taken by seven members of a study group at the Minneapolis-Honeywell Regulator Company in March 1959. Assigned to recommend approaches to mission analysis and cockpit layout, this group, led by John W. Senders, James Bailey, and Leif Arneson, had reported to McDonnell that since "this vehicle does not behave like an airplane … . There is no apparent need for a complex, highly integrated display configuration at a sacrifice of reliability."56 Jones studied the Minneapolis-Honeywell reports carefully and said they expressed a "wooden man" approach. Assuming pilot safety would be provided for, Jones believed more provisions should be made for the pilot to assure mission success. In August, Jones and a colleague, David T. Grober, wrote for Yardley a description of the quantifiable differences between flying this spacecraft and flying aircraft. They admitted: "Primary control is automatic. For vehicle operation, man has been added to the system as a redundant component who can assume a number of functions at his discretion dependent upon his diagnosis of the state of the system. Thus, manual control is secondary."57 But Jones and Grober pointed to at least eight ways in which automation for reliability could interact with the autonomy of the astronaut to vary the chances both for pilot safety and for mission success. They warned McDonnell's reliability engineers against assuming, as they had in their latest formal reliability program given STG, that the reliability of the astronaut is unity:

It has been assumed naively by those who are not familiar with the capsule that the operation of the systems will not be difficult because of the automatic programming of the normal mission and because of an assumed simplicity of the systems. However, preliminary analysis indicates that the operation of the capsule, considering the stringent mission requirements and the physiological environment, will be as difficult or probably more difficult than high performance aircraft. A vast number of different potential malfunctions may occur in the capsule's systems, and the isolation of these malfunctions can be extremely difficult. Mission reliability determinations assume the astronaut can detect and operate these systems without error.

Only three months later Jones read a paper before the American Rocket Society that, while not a reversal of primary and secondary control modes for the manned satellite, marked a symbolic shift from automation to monitored automatic flight. Man's function in space flight, argued Jones, should now be recognized as something more than secondary, if still less than primary:

Serious discussions have advocated that man should be anesthetized or tranquillized or rendered passive in some other manner in order that he would not interfere with the operation of the vehicle … . As equipment becomes available, a more realistic approach evolves. It is now apparent with the Mercury capsule that man, beyond his scientific role, is an essential component who can add considerably to systems effectiveness when he is given adequate instruments, controls, and is trained. Thus an evolution has occurred … with increased emphasis now on the positive contribution the astronaut can make.58

Jones spoke, presumably, of the general attitudes prevailing around McDonnell. His fellow psychologist in STG, Robert B. Voas, supported his evaluation.

Nevertheless, until some Mercury missions were flown automatically to qualify the integration of all systems, man would not be allowed to fly one. Of all the critical systems in Mercury, therefore, the automatic controls, a part of which was the "autopilot," were most crucial for man-rating the capsule.