Chapter 8

Machine-Rating the Men

(January - June 1960)

JUST as the safety of the pilot flying the Mercury mission depended primarily on the reliability of the boosters, so the overall success of the mission would depend primarily on the adaptability of the man inside the capsule. This proposition, recognizing man and machine as directly interdependent, had been far from evident at the beginning of the project. But by the middle of 1960 the developers of Mercury had encountered enough troubles with various automatic systems to dissipate much of their faith in automata. They began to believe that it might be simpler to train toward human perfection and safer to teach the operations team to act automatically than to try to make electromechanical systems operate faultlessly. If the gaps left after technologically man-rating the machines could be filled with techniques learned by machine-rating the men, then lack of experience need not jeopardize either the man or the mission.

Early in 1960 two peerless feats in hydronautics complemented mankind's first infantile steps toward astronautics. Two uncommon vessels named Trieste and Triton, sponsored by the United States Navy, made voyages probing the plenum of the seas only a year before men became able to venture upward into the near vacuum. While "space" was being defined popularly as the region above the atmosphere and below the ionosphere, man also conquered the aqueous seven-tenths of Earth's surface space between the atmosphere and the lithosphere for the first time in history. Demonstrating remarkable closed ecological systems and significant integrations of men and machines, the Trieste descended to the bottom of the deepest known point in the oceans and the Triton "orbited" the Earth underwater.1

The Trieste and Triton voyages symbolized an accelerating translation of science fiction into fact at the beginning of the sixth decade of the 20th century. These voyages not only dramatically demonstrated man's ability to explore and pioneer new frontiers but they also symbolized some complex interrelationships in the sociology of science, invention, innovation, and discovery. Project Mercury likewise promised to exhibit the social energy of a civilization intimately interlocked with industrial technology, governmental organization of manpower, and an accumulation of usable knowledge. Motivationally, too, Mercury grew out of the curiosity, courage, and creativity of individual men who wanted to do "unnatural" deeds. An age-old question of humanistic inquiry - what is human nature? - seemed to become rhetorical, and, as preparations for manned space flight neared completion, inverted: what is not natural to man?

No one doubted at the beginning of 1960 that someone was going upward into space shortly, but precisely who, when, where, and even why were highly controversial questions. NASA Administrator T. Keith Glennan predicted the first Mercury suborbital flight within the year. Soviet spokesmen previewed their mid-January rocket tests over the Pacific as a preparation for placing man in space. Winds from conflicting opinions expressed by political, military, scientific, and industrial critics of American policy regarding space technology began to brew some squalls when NASA asked that almost $108 million of its total budget request of $802 million be appropriated for manned space flight development in fiscal 1961. Whether Mercury would finally cost $250 or $350 million, as was now variously estimated, it would still be a small fraction of the cost of the great Saturn rocket, not to mention other NASA projects.2

While the Eisenhower administration rejected the "space race" image attached to Mercury, Congress pressed for a greater sense of urgency, NASA Headquarters sought supplemental funds, and the Space Task Group concentrated on reconciling schedules with quality control. There was a detente in the cold war until the controversial U-2 incident in May 1960. But even during this thaw STG, as the technical coaching staff for the prime American contestant, became steadily more enmeshed in the confused competition between the United States and the Soviet Union to be first with its man in space. While Maxime A. Faget was being honored as one of the top 10 young men in government service for his designs of the Mercury capsule, couch, and escape concepts, Abe Silverstein stated publicly, "We feel no urgency to move the program unsafely." But the political pressure to produce would increase rapidly as 1960 wore on.3

At the end of January, Little Joe 1-B finally, with a boilerplate capsule, proved the basic aerodynamic viability of the Mercury abort concept. McDonnell Aircraft corporation's first production hardware, which happened to be capsule No. 4, was delivered on demand only half-finished to Langley, where it was fitted with instruments like Big Joe's for the first flight to mate the Atlas booster with the "real McDonnell" head. As it turned out, the only other flight test for Mercury during this half year occurred at Wallops Island on May 9. There and then, McDonnell's Mercury capsule No. 1, so named because it had been first on the assembly line, was yanked by its escape rocket from the beach abort position to begin successfully the qualifying flights for the McDonnell capsule. It took only 14 months to build and deliver this first capsule with its most critical systems ready to be qualified for basic technical performance. Meanwhile qualification tests in laboratories began in earnest. No mechanisms were more difficult to qualify than those most intimately related to the human system.

Controlling the Hostile Environment

To replace the old warhead payloads with inhabitable cockpits on the missiles used to transport man into space required reliable, lightweight means of sustaining life beyond the atmosphere. When man ascends from the bottom of the ocean of air where life as we know it has evolved, he must stay inside a pressurized cell of air or die in the vacuum of space. Engineering the environmental cocoon to provide the basic metabolic needs of man became, through 1959 and 1960, one of the most complex and critical aspects in Mercury's development. Aristotle's classical anthropocentric elements - earth, water, air, and fire - correspond roughly to man's need for the gravisphere and atmospheric pressure, for hydration and waste disposal, for oxygen to breathe through lungs and skin, and for temperature and humidity control. Safety required that these life systems be redundant wherever feasible. The oxygen envelope, for instance, should be contained within the welded walls of the pressure vessel, but in case of leak, puncture, or blowout, the astronaut would wear a suit that was a second inner casing, fully capable of life support in a decompressed capsule.4

The environmental control system for Mercury, logically divided into the cabin and suit subsystems, grew directly out of previous aviation experience in maintaining men and machines at high altitudes. McDonnell had to seal hermetically the pressure vessel within prescribed limits; a subcontractor developed the dual air-conditioning system. Because the clothing needed for space travel turned out to be unavailable from the shelves of government issue, another subcontractor was called upon to make a full-pressure suit that would in effect be a secondary cabin.

When McDonnell and STG engineers first considered the problems of the pressurized cabin, they sought the experience of the foremost company of industrial specialists on the subject. AiResearch had grown since the 1930s into the Manufacturing Division of the Garrett Corporation, the Nation's primary supplier of the needs of the pressurized flight industry.5 In January 1959 the three groups began to discuss the most realistic design criteria for ambient and partial gas pressures, air and water regeneration methods, thermostats, and heat exchangers. R. A. Fischer, Edward H. Olling, and Richard C. Nelson of Garrett, Herbert R. Greider, John R. Barton, and Earl A. Reed of McDonnell, and Stanley C. White and Richard S. Johnston of STG were the principal designers of this system.

While the process of fabricating the pressure-vessel shell by the fusion-welding techniques of William Dubusker and his production engineers was cut and tried on the factory floor, the important question of cabin atmosphere gas composition was being debated by physicians and physicists. Should the cabin air and pressure imitate "sea level" air mixtures of nitrogen and oxygen, or should the space cabin endorse the experience of aviation and use at highest altitude whatever would guarantee oxygenation?6 Stanley White championed the latter position forcefully, in response to rather late outside criticism that "shirtsleeve" environmental air might be preferable. John F. Yardley and Barton, Faget and Johnston agreed emphatically that a five-pound-per-square-inch pressure of pure oxygen would be far more practical for saving weight, controlling leakage, and avoiding the extremely difficult problem of providing reliable oxygen partial-pressure sensors. Faget explained STG's choice:

The most important consideration in choice of a single gas atmosphere is reliability of operation. If a mixed gas atmosphere were used, a major increase in complexity in the atmospheric control system and in monitoring and display instrumentation would have resulted. Furthermore, the use of a mixed gas system would have precluded the use of simple mechanical systems for a great number of these functions which in itself would have decreased the reliability of performance.7

Reduced to practice, these designs had evolved into hardware for three spherical oxygen bottles, tested at 7500 pounds per square inch, with simple regulator valves, a lithium hydroxide canister to remove carbon dioxide and odors, an evaporator heat exchanger (its water would boil around 35 degrees F at a 100-mile altitude), and a simple pulsating-sponge water removal system, all to be located beneath the astronaut's legs. Blowers, a fan, snorkels, and plumbing were also included to make the capsule livable under the extremely diverse conditions existing before, during, and after an orbital mission. The most novel parts of this system were the high-pressure oxygen bottles, the use of lithium hydroxide, and the "sponge squeezer" to collect perspiration and respiration water vapor from the cabin atmosphere. Cleanliness in the manufacture of these components was so important that AiResearch built the first "surgery," or "white room," for Mercury fabrication in the summer of 1959.8

McDonnell and AiResearch engineers consulted the voluminous literature on aeromedicine before imposing STG's specific requirements on top of the state of their art. One of the best independent guides to that state was a report prepared in mid-1959 by A. B. Thompson of Chance Vought Astronautics, entitled "Physiological and Psychological Considerations for Manned Space Flight." Thompson compiled a consensus on environmental parameters derived from a wide number of sources; then he presented these factors systematically in the order of their occurrence on a typical orbital mission. Concerning the internal atmospheric environment, he drew heavily from submarine, as well as aviation, practice and expressed particular concern over abnormal toxicities peculiar to space conditions. Regarding temperature tolerance, Thompson wrote:

Man can exist and carry out simple tasks in environmental temperatures from - 40° to 140° if suitable clothing is worn for the low, if humidity is kept at 30-50% for the high. Time of exposure to high temperatures should be well below man's tolerance limits. Up to 160°F can b withstood for 20 minutes. Such temperature highs are possible at reentry into atmosphere. Insulation, double walls, cabin temperature and atmosphere cooling should limit the heat of cabin to less than 140°F even when skin temperatur of the vehicle is much higher.9

Between John Barton of McDonnell and Edward Olling of AiResearch, the system specifications for environmental control began to emerge in mid-1959, subject to continuous reappraisal as other systems also took shape. Their original set of design parameters rather arbitrarily selected 400 British thermal units per hour for one man's average heat production rate over 28 hours, and an ambient pressure of 5 pounds per square inch circulating through the cabin, with a breathable supply of oxygen at the partial pressure of 3.8 pounds. An assumed oxygen consumption rate of 500 cubic centimeters per minute allowed a slight margin for suit leakage. Setting the average rate of perspiratory and respiratory water production at 6 pounds per day dictated the weight and size of their system's hardware.

Particularly knotty for the development of the active air-conditioning system and the passive insulation to control the cabin temperature was a problem that Barton described in terms of applied thermodynamics:

Studies of launch, orbit and reentry heating effects disclosed that the insulation requirements for the cabin side-walls for the orbit and reentry phases were diametrically opposed. In orbit it is desirable to lose heat from the side-walls and during reentry it is necessary to prevent the entry of heat. The reentry phase, being more critical, dictated the side-wall insulation. In orbit, the insulation becomes an almost perfect heat barrier and dictates that the cabin cooling be primarily accomplished by the cabin heat exchanger.10

At the end of July 1959, Barton and Frank G. Morgan, Jr., met with 18 STG engineers, including all the astronauts, to describe the basic designs and developmental problems, especially leaky instrumentation fittings, for the system now known as "the ECS." Faget, White, William K. Douglas, William S. Augerson, and Robert B. Voas, and the ECS systems engineers, Richard Johnston, Frank H. Samonski, and Morton Schler, all warned that the design parameters were set too low. They demanded larger margins of at least 1000 British thermal units per hour for astronaut heat generation, at least 7 pounds per day assumed water production, and certainly no less oxygen pressure in the suit than in the cabin.11 Greider and Barton warned the astronauts to learn early and thoroughly the symptoms of hypoxia in themselves so they could take action soon enough to ensure an emergency oxygen supply. Otherwise probe sensors of some sort in the nostrils or the lungs might be necessary.

McDonnell hurried the building of a "man-rating" environmental system test chamber through September 1959, so that a reliability test program for each subsystem could be conducted, complete systems tests could be scheduled, and astronaut familiarization training could begin as soon as possible. By the end of the month, Gilbert B. North, as McDonnell's test astronaut, had endured so many failures or inadequacies in the bench testing that STG sought the aid of physiologists from Duke University School of Medicine and from the Navy Air Crew Equipment Laboratory in Philadelphia to help speed the man-rating of the environmental control system. At the end of January 1960, neither the cabin nor the suit environmental control system had passed its test to operate as designed for 28 hours. Richard Johnston reported that experience with the system was still "rather meager." He urged aeromedical investigators to provide more "realistic metabolic data" for his engineers to use in system redesign.12

Difficulties with the body ventilation and post-landing snorkel ventilation subsystems continued troublesome through 1960. Extensive testing at AiResearch and intensive manned tests at McDonnell beginning in June slowly eradicated most of the "bugs" plaguing the reliability of the environmental control system. A robot "crewman simulator," designed primarily by Charles F. Jahn and Eugene Wulfkehler at McDonnell, served to calibrate the physical parameters for average human inputs and outputs to this closed ecological system. Then, too, Gilbert North and Herbert Greider learned to outwit the peculiarities of the mechanisms to avoid hypoxia, dysbarism, and hyperventilation. The initial manned tests of the ECS hardware were endured by McDonnell volunteers; occasionally the Mercury astronauts would observe. Gas analysis problems delayed the accumulation of reliability records and the verification of certain operational procedures, such as ground purge and ground cooling, until early 1961.13

Suiting up for Space

The pressure suit for Project Mercury was designed and first developed during 1959 as a compromise between the requirements for flexibility and adaptability. Learning to live and move within aluminum-coated nylon and rubber garments, pressurized at five pounds per square inch, was like trying to adapt to life within a pneumatic tire. Led by Walter M. Schirra, Jr., whose specialty assignment this was, the astronauts literally wrestled with the most elementary problem in becoming machine-rated - wearing the suit.

Back in February 1959, Maxime Faget and Stanley White became convinced that the so-called "pressure" suits being used by Air Force and Navy test pilots were rather "high-pressure" and partially anti-g flying suits. Ever since 1947 the Air Force and the Navy, by mutual agreement, had specialized in developing partial-pressure and full-pressure flying suits, respectively, but a decade later neither type was quite satisfactory for the newest definition of extreme altitude protection. Such suits would require extensive modifications, particularly in their air circulation systems, to meet the needs of the Mercury space pilots. The first suit conference on January 29, 1959, attended by more than 40 experts in the art of tailoring for men engaged in high-altitude flying, had recommended an extensive evaluation program.14 Through the spring three primary competitors - the David Clark Company of Worcester, Massachusetts (a prime supplier for Air Force pressure suits), the International Latex Corporation of Dover, Delaware (a bidder on a number of government contracts involving rubberized material), and the B. F. Goodrich Company of Akron, Ohio (suppliers of most of the pressure suits used by the Navy) - competed to provide by the first of June their best products for a series of evaluation tests.

Few systems in the Mercury program were modified as frequently or as drastically as the space suit. Shown here are an early model worn by Slayton in 1960.

The end-of-Mercury model.

NASA had requested the Air Force Aeromedical Laboratory at Wright Air Development Center and the Navy Air Crew Equipment Laboratory in Philadelphia to plan and perform evaluations of the different test suits before mid-July. The Clark and Goodrich suits ranked highest in both evaluation programs, but predictably the Air Force favored the Clark suit and the Navy the Goodrich suit. After an evaluation conference on July 15 at Langley, the chairman, Richard Johnston, informed all parties of STG's decision to work with both the Clark and the Goodrich companies for several more months to allow further concurrent development and evaluation of various combinations of suits and ventilation systems.15 By the end of August, William Augerson and Lee N. McMillion of STG recommended that "the suit should not be expected to cope with all the deficiencies of the Mercury capsule." The close interface between pressure suit and environmental control system caused enough problems to delay the formulation of suit specifications until October, but Goodrich was awarded the prime contract for the Mercury space suit on July 22, 1959.16

One of the most senior employees of the Goodrich Company was Russell M. Colley. In 1933, Wiley Post returned from the first solo flight around the world and wanted some kind of rubber suit that would enable him to fly his famous aircraft Winnie Mae above the record 47,000-foot altitude. Colley had designed an aluminum helmet resembling those used by marine divers and had stitched together on his wife's sewing machine the first crude space suit. The next year Colley and his company had designed and developed a more flexible flying suit for Wiley Post, with an off-center face plate to accommodate Post's one-eyed vision. In 1952, Colley had designed and helped develop swivel joints of air-tight bearings and fluted fittings for pressure suits fabricated by Goodrich for the Naval Bureau of Aeronautics. In 1959, Colley, along with Carl F. Effler, D. Ewing, and other Goodrich employees, was instrumental in modifying the famous Navy Mark IV pressure suit for NASA's needs in orbital flight.

Although the decision to let the capsule itself provide primary protection minimized the difference between corseted, pressurized g suits and a "space suit" for Project Mercury, the redundant suit environmental control system required complicated modifications and continual refittings.

The Task Group had discovered during 1959 that each Mercury capsule would have to be specially tailored to its own mission objectives. Pressure suits also were designed individually according to use - some for training, others for evaluation and development. Thirteen operational research suits first were ordered to fit astronauts Schirra and Glenn, their flight surgeon Douglas, the twins Gilbert and Warren J. North, at McDonnell and NASA Headquarters, respectively, and other astronauts and engineers to be specified later. A second order of eight suits supposedly would represent the final configuration and provide adequate protection for all flight conditions in the Mercury program.

The three major parts of the space suit - the torso coveralls, the helmet, and the gloves - were fabricated by techniques and procedures similar to those already in use in the manufacture of full-pressure flying suits. But the air system operation was unusual:

The Mercury headpiece is a single cavity design with suit ventilation air exiting through the exhaust valve located in the right cheek area. This system is known as the "closed" or "single gas" system and utilized one air source for ventilation as well as breathing. This concept, which is desirable in space missions, permits simplicity of design and minimum weight of the ventilation and respiration equipment.17

According to Lee McMillion of STG's Life Systems Branch, the Big Joe reentry heating test in September 1959 allowed the developers of the pressure suit to remove much of the insulation previously thought necessary. This improved somewhat the mobility of the astronaut under full pressurization. By the end of the year McMillion, Colley, Schirra, and Glenn A. Shewmake, STG's "tailor," chose to modify the suit to facilitate mobility in the capsule rather than repattern for a more generally mobile suit. Schirra had felt many pressure points and was severely constricted in recent tests. His discomfort was traced to the design conservatism that had accepted the g suit and oxygen mask concepts used for the Navy Mark IV and Air Force X-15 flying suits. Furthermore, each time these prototype space suits were pressurized and worn, they stretched out of shape.18

Throughout the spring of 1960, fittings and tests with new textiles, different materials, and other human models continued until they finally solved the stretching problem. In mid-March a committee of eight members from STG, McDonnell, the Navy, and Goodrich decided on the final design features for the Mercury space suits. All kinds of minor troubles with zippers, the visor, the segmented shoulder, lacings, straps, snaps, seams, valves, underwear, gloves, microphones, and neck dams continued. But after a "gripe session" in mid-May 1960, the astronauts and their tailors essentially agreed on what the well-dressed man should wear into space.19

During an orbital flight, certain physiological limitations were expected to establish the requirements for matching man and machine in one smoothly functioning system.20 In the area of noise and vibration, for example, research during the 1950s had led to the conclusion that 140 decibels, in the broad spectrum between 100 and 12,000 cycles per second, was the most that man could stand for durations of four or five seconds. Acceleration tolerances were rising, thanks to knowledge gained by centrifuge and rocket sled tests, but above 6 g pilots could breathe only by forcing abdominal constriction and could move effectively only their hands and fingers. An oxygen pressure inside the lungs corresponding to that of 100 millimeters of fluid mercury was judged necessary to preclude any symptom of hypoxia. To guard against the danger of "bends" (caisson disease or dysbarism), the cabin pressure should not be more than twice the suit emergency pressure of 180 millimeters of mercury. No more than two percent of carbon dioxide by volume at sea level should be permitted.21 Other limitations, including extremes of temperature, humidity, radiation, and accumulating toxic gases from carbon monoxide, ozone, metal, and plastic fumes, also became "human parameters." Warning instruments in the capsule relied primarily on stimulating the astronaut's senses of sight and sound; psychologists also studied the feasibility of using his senses of touch and smell to aid him in diagnosing malfunctions.22

During the fifties academic and medical studies in sensory deprivation made an important, if indirect, contribution to the building of the spacecraft and the training of the astronauts. Made notorious by the experience of American prisoners of war who had been isolated and "brainwashed" in North Korean prison cells, the effects of isolation were attacked on many fronts. At McGill University, in Canada, at the University of Rochester in New York, and at the National Institute of Mental Health in Bethesda, Maryland, famous sensory deprivation experiments reduced all physical stimuli to near zero. Suspending people in water of body temperature in blacked-out, soundproof rooms at Bethesda revealed that normal men, regardless of their motivations, could hardly stay both conscious and sane if deprived of all sensory stimuli beyond three hours. Physicians and psychiatrists were warning in 1956 and 1957 that

if one is alone enough and at levels of human and physical stimulation low enough, the human mind turns inward and projects outward its own contents and processes… . Man's mental state is dependent on adequate perceptual contact with the outside world… . Isolation produces an intense desire for extrinsic sensory stimuli and bodily motion, increased suggestibility, impairment of organized thinking, oppression and depression, and in extreme cases, hallucinations, delusions, and confusion.23

Such background studies strengthened aeromedical demands, originating outside NASA and STG, for continuous communications between the ground and an orbiting man, for increasing the number of meaningful cues to be given the man in space, and for accenting significant tasks to be performed by the man inside the capsule. There was room for controversy here, but STG and NASA believed the hypothetical risks did not justify the very large outlay of money, men, and time that a continuous communication network would have required.

If outside advice of this type was not always taken, there was still a conscious effort to solicit it. One of the most useful means of dialogue was the presenting of papers at meetings of professional societies. The size, lead time, and innovating nature of Project Mercury, together with the impetus from NASA's open information policy, all reinforced the normal professional obligation to inform and meet the judgment of one's colleagues. Thus it was that, on January 25, 1960, several leading engineers from the Space Task Group were in New York for the annual meeting of the Institute of Aeronautical Sciences and presented papers reviewing the scope and recent results of their research and development program.24 In one of these, Charles W. Mathews set forth the operational plans for the orbital mission. He did not mention the role of the pilot until the end of his remarks. He then offered a summary list of eight activities to illustrate what the astronaut must be prepared to do: the Mercury pilot should communicate with ground stations, make scientific observations, monitor onboard equipment, control capsule attitude, navigate and fire retrorockets, initiate emergency procedures, activate escape system if necessary, and deploy landing parachute if required. Any one of these activities could conceivably save the mission.25

The degree of control over his own destiny that the astronaut might have during the first orbital flights steadily increased throughout 1959 by virtue of the development of two new semi-automatic control systems: fly-by-wire, interposed in the automatic stabilization and control system (ASCS), and the rate command system (rate stabilization control system, or RSCS), superimposed on the manual proportional control system. Further elaboration and sophistication of the hardware took account of man's flexibility by providing for the use of more than one system at a time. In addition to the "last resort," or manual-proportional, method of attitude control, other uses of the astronaut as a source of mechanical power were being incorporated to the mutual advantage of reliability and flexibility. Turnkey handles and pull rings were added to duplicate virtually every automatic function of the mission sequence.

In April 1960, Edward R. Jones, the chief psychologist at McDonnell, feeling that a vigorous defense is the best defense, argued in public that man in the Mercury capsule not only could act as an observer as well as the observed but should be considered an integral part of the system to increase the probability of mission success. Having just completed extensive studies of man's vision from the new centerline window, Jones supervised studies of other expected sensations during the Mercury orbital flight.26 As the hardware and manned capsule systems tests progressed, Jones had more reason for his optimism about man's ability to perform effectively in space, once his life-support requirements were met. Concerning higher mental processes, Jones, speaking in a symposium at the Iowa Academy of Science, where James A. Van Allen represented the instrumentalists and John Paul Stapp represented the experimental physicians, maintained his positive approach:

Most of the astronaut's tasks will involve complex mental activity even though some may be on a near reflex level as a result of constant practice. It is not expected that impairment of these functions will occur under normal vehicle operation. Stress and an abnormal atmospheric composition, if present, could cause some impairment of the higher mental functions.

It should be apparent that the training of the astronaut in the operation of the space vehicle will be critical. Much of the physiological training and conditioning will be given on a part task basis in human centrifuges, and pressure and heat chambers. The operation of the vehicle can be practiced over and over again in a capsule simulator … built for Mercury. Overlearning far beyond the point that apparent progress stops seems to be the best guarantee that the astronaut will have developed response patterns that are least apt to deteriorate under the stresses of orbital flight.27

Seven Astronauts-In-Training

When the astronauts first had reported to the Task Group at the end of April 1959, they had been oriented with a series of lectures covering every aspect of STG's progress. After a welcoming general briefing by Paul E. Purser, Alan B. Kehlet delivered their first lecture on April 29, explaining the configuration and the escape system. Following two weeks of such lectures, the group began to visit contractor facilities for familiarization with mockups, hardware, and manufacturing processes. They went to the launch site at Cape Canaveral. At various military and medical centers, each man learned to know himself still better through training sessions in the pressure suit, in heat chambers, in heavy concentrations of carbon dioxide, and in parabolic flying. By July, Robert Voas, the astronauts' training officer, had prepared tentative curricula and schedules; during unscheduled times, each man was expected each week to fly for three hours, to spend six hours on his specialty area, and to exercise at least four hours in athletics. The primitive jury-rigged air-bearing platform trainer also was ridden by each astronaut for two hours per week at first.

During August 1959, each man spent approximately two weeks at Johnsville riding the centrifuge in "closeloop" (i.e., with man in the control circuit) simulation of the exit and reentry profiles. In September each man spent a week at McDonnell, another at the Cape for the Big Joe shot, and another at the Goodrich plant in Akron being fitted for his pressure suit. And in October 1959, the seven pilots, by now reluctant celebrities, traveled to Edwards and Vandenberg Air Force Bases, to the AiResearch and Convair factories, and to the Naval School of Aviation Medicine at Pensacola for different kinds of centrifuge runs and for training in survival, disorientation, and communications.28

Although everyone who read the news or looked at Life magazine knew that the Mercury astronauts had been assigned specialty areas befitting their profession as engineering test pilots, few could see the logic of those assignments.29 M. Scott Carpenter accepted responsibility for communications and navigation because as a Navy lieutenant he had had special training in airborne electronics and celestial pathfinding. Virgil I. Grissom, who had earned a degree in mechanical engineering from Purdue University in 1950, became the expert for the group on the complicated electromechanical, automatic, and manual attitude-control systems. The senior man in age and date of rank, John H. Glenn, Jr., had the most experience in flying varieties of aircraft and could therefore make the best contribution to cockpit layout. Walter M. Schirra, Jr., born to a flying family and a graduate of the Naval Academy, took a special interest in life-support systems and the pressure suits. Alan B. Shepard, Jr., like Carpenter and Schirra, had the background training of the naval flier for specializing in tracking and recovery operations. L. Gordon Cooper, Jr., and Donald K. Slayton, both Air Force captains, accepted the jobs of astronaut liaison with the developers of the Redstone and the Atlas boosters, respectively. Cooper, the youngest of the group, had been dedicated to flying since childhood and had worked with performance engineering similar to what he would encounter at Redstone Arsenal. And Slayton, with a degree in aeronautical engineering from the University of Minnesota and having worked for two years with the Boeing Company in Seattle, was best fitted to report on the progress of the Atlas booster at Convair/Astronautics.

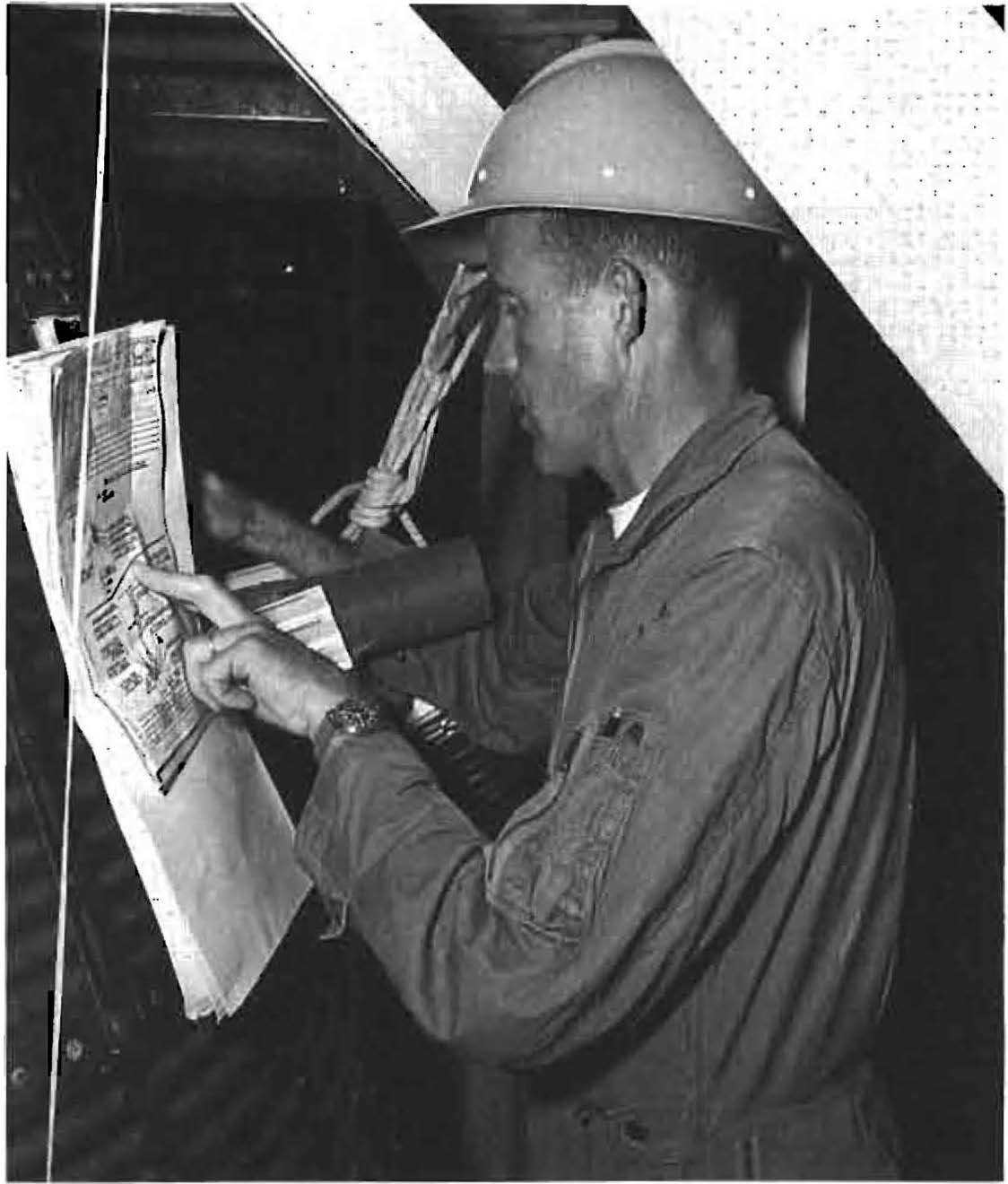

Just as they did as military test pilots before they joined the Mercury program ,each astronaut felt his first responsibility to be that of the engineer-test pilot responsible for knowing his spacecraft and its equipment so well that he could quickly and with certainty evalu ate its performance. In these photos, Cooper performsan engineering check on a spacecraft.

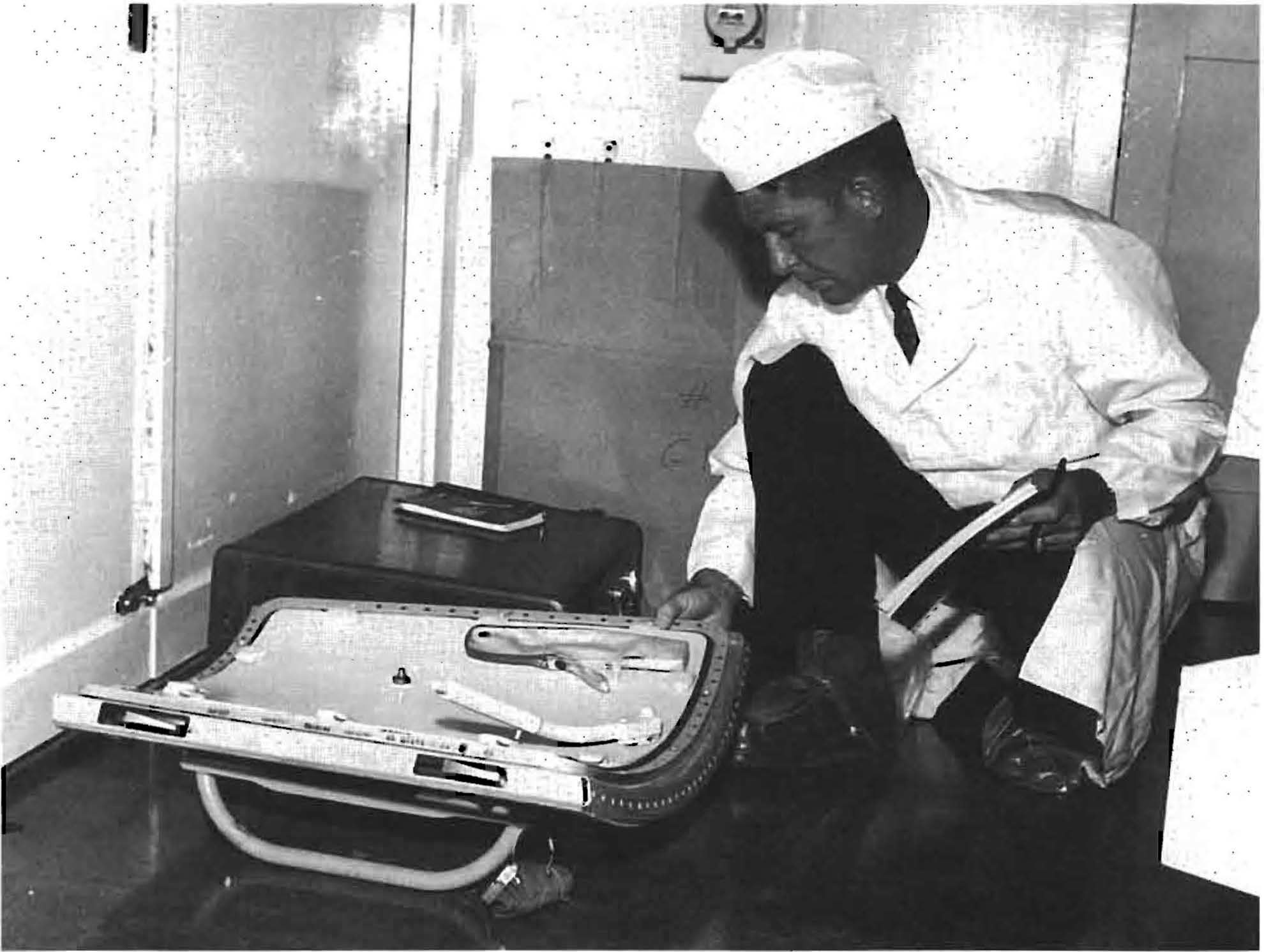

Schirra inspects a hatch in white room at the McDonnell Aircraft Corp. plant.

The astronauts' specialty assignments had some direct effect on the redesign of the Mercury suit, cockpit layout, and capsule hatch and window systems. More importantly, the assignments kept the crew informed in depth on the problems and progress in major areas of concern to all members. Carpenter and Shepard kept tabs on the progress of the Tracking Unit at Langley and of the Goddard Space Flight Center in preparing to operate the network. While Carpenter monitored the development of onboard navigation equipment, such as the Earth-path indicator and starfinder charts, Shepard paid special attention to recovery at sea and to problems of egress from the capsule and survival on Earth in inhospitable environments. Grissom studied the electromechanical worries of Robert G. Chilton, Thomas V. Chambers, and other controls engineers. Schirra worked closely with Richard Johnston and John Barton on the environmental system, and with Lee McMillion, Gilbert North, and the Goodrich people in preliminary fittings of the pressure suit. Cooper and Slayton spent much of their time traveling to Huntsville and southern California, respectively, attending meetings and offering suggestions from the pilot's viewpoint on how best to mate a manned capsule with the Redstone and Atlas missiles. Glenn, meanwhile, paid special attention to optimizing the cockpit and improving simulation training.30

Within months after joining the Space Task Group, the more eager than anxious astronauts found themselves barraged by questions regarding their emotional feelings about being catapulted into orbit. In answer to one such set of questions, posed in an author's questionnaire for a high-school textbook, Schirra perfunctorily replied that it was only natural for a test pilot to want to participate in the most advanced form of manned vehicular travel. Schirra's desire to "go higher, farther, and faster" than previously had been possible was to him neither mysterious nor worthy of introspection; it was simply the professional commitment of them all and of STG to want to expand the test pilot's "envelope."31

Partly because of this kind of natural public interest and partly because the civilian space agency had a statutory mandate to conduct educational publicity, NASA Headquarters, after investigation and decision, encouraged the astronauts to stay together and to accept the fringe benefits of a single private-enterprise publishing offer arranged in outline even before their selection. This precluded eventual competitive bidding for individual story rights. On August 5, 1959, the astronauts sold their "personal stories" to the highest bidder, Time-Life, Inc., for $500,000, an amount to be equally divided regardless of who might be chosen first to fly in space. This money was to be paid in installments throughout the program. The astronauts' wives also subscribed to the contract. Defense Department policy had been followed by the NASA decision because the astronauts were active-duty military officers.32 There were similar precedents for test pilots, Presidents, and submarine captains. Many Congressmen approved this form of extra life insurance for the astronauts' wives.

A public furor, nevertheless, arose in the press over these exclusive rights to publish the memoirs of the seven. Few other peripheral policy decisions regarding Project Mercury were to become so controversial in the long run. As the waiting period before an astronaut flew in space stretched on, public interest grew; the competition among newsmen and media increased; the line between personal and public domains blurred. NASA and STG were forced to contend with no small amount of adverse and even spiteful publicity from indignant correspondents who were not of the favored few. Warren North, two days after this contract was signed, advised Silverstein about it and warned of other impending difficulties, including a loss of privacy to a degree the astronauts might not have anticipated.33

The agreement, arranged without fee by C. Leo DeOrsey, a prominent Washington lawyer and sportsman, assigned all magazine and book rights to Time-Life, Inc., for "non-official" feature stories on the astronauts and their families. Since it was cleared by NASA's legal and public relations chiefs, John Johnson and Walter T. Bonney, the astronauts and the Task Group had to adapt themselves to this policy. John A. "Shorty" Powers, at least, was relieved of one headache and was not displeased with the arrangements.34

Although Robert Voas at first had designed an orderly curriculum for the astronauts, their activities soon became so diverse and the group separated on sorties for their specialties so often that the academic approach became impossible. The coordination of astronaut training became his chief duty. Voas gathered and trained a team of training specialists. George C. Guthrie had responsibility for improving training aids, procedures, and simulation devices; Raymond G. Zedekar arranged the lecture series; Stanley Faber conducted the four-phase centrifuge training program on the Johnsville "wheel." By the end of 1959, each of the astronauts had trained for about 10 hours riding the gondola at Johnsville. Voas, meanwhile, turned his attention to an extensive astronaut task analysis, which paralleled the work of Edward Jones at McDonnell.35 Just before Christmas 1959, John Glenn privately described his training experiences in a letter to a friend and fellow pilot:

This past 8 or 9 months has really been a hectic program, to say the least, and by far the most interesting thing in which I have ever taken part, outside of combat.

Following our selection in April, we were assigned to the Space Task Group portion of NASA at Langley Field, and that is where we are based when not traveling. The way it has worked out, we have spent so much time on the road that Langley has amounted to a spot to come back to get clean skivvies and shirts and that's about all. We have had additional sessions at Wright Field in which we did heat chamber, pressure chamber, and centrifuge work and spent a couple of weeks this fall doing additional centrifuge work up at Johnsville. This was some program since we are running it in a laydown position similar to that which we will use in the capsule later on and we got up to as high as 16 g's. That's a batch in any attitude, laydown or not.

With the angles we were using, we found that even lying down at 16 g's it took just about every bit of strength and technique you could muster to retain consciousness. I found there was quite a bit more technique involved in taking this kind of g than we had thought. Our tolerances from beginning to end of runs during the period we worked up there went up considerably as we each developed our own technique for taking this high g. A few runs a day like that can really get to you. Some other stuff we did up there involved what we call tumble runs or going from a plus g in two seconds to a minus g and the most we did on this was in going from a plus 9 g to a minus 9 g. Obviously a delta of 18… . When we first talked about doing this, I didn't think it would be possible but in doing a careful buildup we happily discovered that this was not so horrible. At plus 9 g to minus 9 g we were bouncing around a bit but it was quite tolerable.

* * *

We just finished an interesting activity out at Edwards AFB doing some weightless flying in the F-100. This was in the two-place F-100 so that we could ride in the rear seat and try various things such as eating and drinking and mechanical procedures while going through the approximately 60 second ballistic parabola that you make with a TF-100. That started at about 40,000 feet, 30 degrees dive to 25,000, picking up about 1.3 to 1.4 mach number, pull out and get headed up hill again at 25,000 and about a 50 degree or 60 degree climb angle, at which point they get a zero-g parabola over the top to about 60 degrees downhill.

You can accomplish quite a bit in the full minute in those conditions and contrary to this being a problem, I think I have finally found the element in which I belong. We have done a little previous work floating around in the cabin of the C-131 they used at Wright Field. That is even more fun yet, because you are not strapped down and can float around in the cabin doing flips, walk on the ceiling or just come floating the full length of the cabin while going through the approximately 15 seconds of weightlessness that they can maintain on their shorter parabola. That was a real ball and we get some more sessions with this machine sometime after the first of the year.36

Seasoned rocket experts, especially in Wernher von Braun's group, were worried early in the program over the human tolerance to noise and vibration at the tip of a missile leaving Earth's atmosphere. Biomedical experimentation during the fifties had almost, but not quite, confirmed that a man literally can be shaken to death by sympathetic vibrations induced through various harmonics upon certain organs. No one was yet sure whether the 140-decibel noise limit would be attenuated enough by the double-walled capsule and the astronaut's helmet to keep him comfortable and able to communicate.37 In February 1960, a representative from the Army Ballistic Missile Agency at Huntsville proposed a training project in which astronauts would experience controlled noise and vibration inside a simulated Mercury capsule mounted above a Jupiter engine being static-fired. The astronauts' personal physician, William Douglas, objected vehemently and saved the astronauts from this ordeal. Internal acoustic measurements in the capsules riding Big Joe and Little Joe 2, however, gave concern that aerodynamic noise at max q might blot out communications if it approached the 140-decibel limit. The astronauts decided to condition themselves to loud noises in other ways by occasionally stationing themselves near the blow-down exhausts of the wind tunnels around Langley. Carpenter, supported by the environmental control system in capsule No. 3, sat through these static noise tests and proved that communications remained satisfactory in spite of extremely loud outside noises.38

Other carefully controlled trials by ordeal were arranged to teach the astronauts how best to survive for a time anywhere on Earth beneath their planned orbital track. During the spring and summer of 1960, capsule egress training, and water, desert, and jungle survival courses were instituted for their benefit. So exotic and picturesque were these excursions that publicity photographs flooded the news media.39

Serious consideration was not given to the use of a personal parachute, with which the astronaut might bail out from his explosive side hatch, until May 1960, when Lee McMillion and Alan Shepard suggested the idea for the Mercury-Redstone flights at least. The exploits of the Air Force balloonist, Captain Joseph W. Kittinger, Jr., who had been making solo stratospheric ascents for the Air Force since 1957, were a significant factor in this reevaluation of the personal parachute. In Project Excelsior, Kittinger began a series of record-breaking sky dives. On November 16, 1959, he jumped from an open gondola at an altitude of 76,400 feet. Three weeks later, from Excelsior II, he bailed out at an altitude of 74,700 feet to establish a free-fall record of 55,000 feet before pulling his ripcord. STG knew of Kittinger's plans for Excelsior III, which he fulfilled on August 16, 1960, by diving from his balloon at 103,000 feet and falling 17 miles before opening his chute at 17,500 feet. If Kittinger could do it, so might the Mercury astronaut in case the escape tower would not jettison or both main parachutes failed on a Mercury-Redstone flight.40

Although supposedly the first phase of astronaut training through 1959 was to concentrate on academic studies in the eclectic new field of "space science," the astronauts did not relish book-learning at the expense of field trips, specialty assignments, and familiarization with the developing hardware. As soon as new training aids and partial simulators became available, they would make full use of them. Late in 1959, however, the only operable flight simulator was a crude "lash-up" of analog computers driving a cockpit panel display above a couch on an air-bearing floating platform at Langley. Gradually STG engineers Harold I. Johnson, Rodney F. Higgins, and George Guthrie built more sophistication into this special kind of Link trainer. By January 1960 they were calling it the Air Bearing Orbital Attitude Simulator. In use and development simultaneously through 1960, this machine slowly evolved into a major training aid called the ALFA (for "air lubricated free attitude" [or axis] ) trainer. McDonnell provided a capsule shell as an egress trainer in mid-February 1960. But the most valuable and elaborate training aids were the two McDonnell-built simulators called "procedures trainers." One for team training at the Cape and another at Langley were installed and in use by April 1960. Through long hours of practice in these procedures trainers, the astronauts "overlearned" their tasks, as Jones had recommended, so that they would act almost reflexively during their mission sequence.

During the first year of the astronaut training program, the seven pilots heard approximately 50 hours of space science lectures given primarily by senior members of the Langley Research Center. Elementary mechanics and aerodynamics made up 10 hours of this time. Formal presentations in space physics took up 12 hours. Other courses included principles of guidance and control (4 hours), navigation in space (6 hours), elements of communications (2 hours), and basic physiology (8 hours). Each astronaut spent approximately 8 hours at Morehead Planetarium at the University of North Carolina on star recognition and practicing celestial navigation.41

"Phase Two" of the training program, based on simulation training and engineering involvement, was to begin with the new year. But concurrent developments, individual study, and personal practice in various areas complicated the astronauts' training calendar. At the end of one full year of assignment to STG, each of the seven had spent approximately 10 days in St. Louis at the McDonnell plant; five days in San Diego at the Convair/Astronautics factory; and two days each at the Cape, at Huntsville, at Edwards Air Force Base, in El Segundo at Space Technology Laboratories and the Air Force Ballistic Missile Division, and at the Goodrich plant in Akron. Each also spent one day at the Rocketdyne factory of North American Aviation to see the engines being produced for the Atlas, another day at the AiResearch shops to meet the makers of their environmental control systems, and yet another at the Los Angeles plant of a subcontractor, Protection, Incorporated, where individual headgear was being molded.42 These visits by the astronauts to the various industrial production lines were found to be so valuable in inspiring craftsmen and technicians at all levels to higher standards of workmanship that these personal contacts between producers and the astronaut-consumers became a regular feature of quality control programs. Grissom's simple remark on a visitation to Convair, "Do good work!" became a motto of incalculable value to every worker who heard it or shook his hand.

Mercury Training Devices

Johnsville centrifuge

Procedures trainer

ALFA trainer

MASTIF trainer

Weightlessness in C-131

Weightlessness in F-100F

Trainers and simulators have for some years been part of all flight training. In the Mercury program the normal training requirement was intensified by the new areas of sensation and orientation that man had never before experienced. Hence the astronauts underwent centrifuge runs at Johnsville, Pa., for g-force training; procedures training at Langley; ALFA training at Langley for pilotage; MASTIF training at Lewis for acquaintance with space disorientation; movement training in weightless condition in C-131 flights at Wright Air Development Center; and piloting experience with weightlessness in supersonic flights at Edwards Air Force Base.

The astronauts also made many field trips to Government installations for familiarization with specific conditions of space flight. In addition to the training for high accelerations on the centrifuges at Johnsville, Dayton, and Pensacola, training for zero acceleration - weightlessness - was distilled from the short parabolic hops that were flown in C-131s at Wright-Patterson Air Force Base and in F-100 aircraft at the School of Aviation Medicine in San Antonio. Closer to their Langley home, the astronauts mastered scuba diving at the Naval Amphibious Base near Norfolk; at their home base swimming pool they practiced floating fully suited. Also immersions in a Langley test tank gave them the sensation of neutral buoyancy. Both at Dayton and Philadelphia the astronauts borrowed military facilities to experience reduced ambient pressures in decompression chambers. For conditioning to withstand high heating rates, the astronauts were toasted in the Air Crew Equipment Laboratory ovens and in a "human calorimeter" at the National Institute of Mental Health at Bethesda. Two facilities at Pensacola, the "rotating room" and the "human disorientation device," provided some experience with induced vertigo. But for complex tumbling experiences, each astronaut spent some time at NASA's Lewis Center in Cleveland, in the curious test device called the "MASTIF." Finally, each man learned to know his own idiosyncrasy to high concentrations of carbon dioxide by experiments also done at Bethesda.

None of the mechanical aids for astronaut training could simulate more than a few of the conditions of space flight at a time. Even the seven Redstone ballistic flights, one planned for each astronaut, would be only partial simulations. Harold Johnson commented in February 1960 that the Redstone flights "may or may not be classified as training missions, depending on how sporting you may be." The astronauts were not only sporting in this regard, they were also chafing at delays. They suggested to Robert Gilruth that a rhesus monkey ride MR-1 so the schedule might be compressed enough to put the first chimp in orbit by the end of November.43

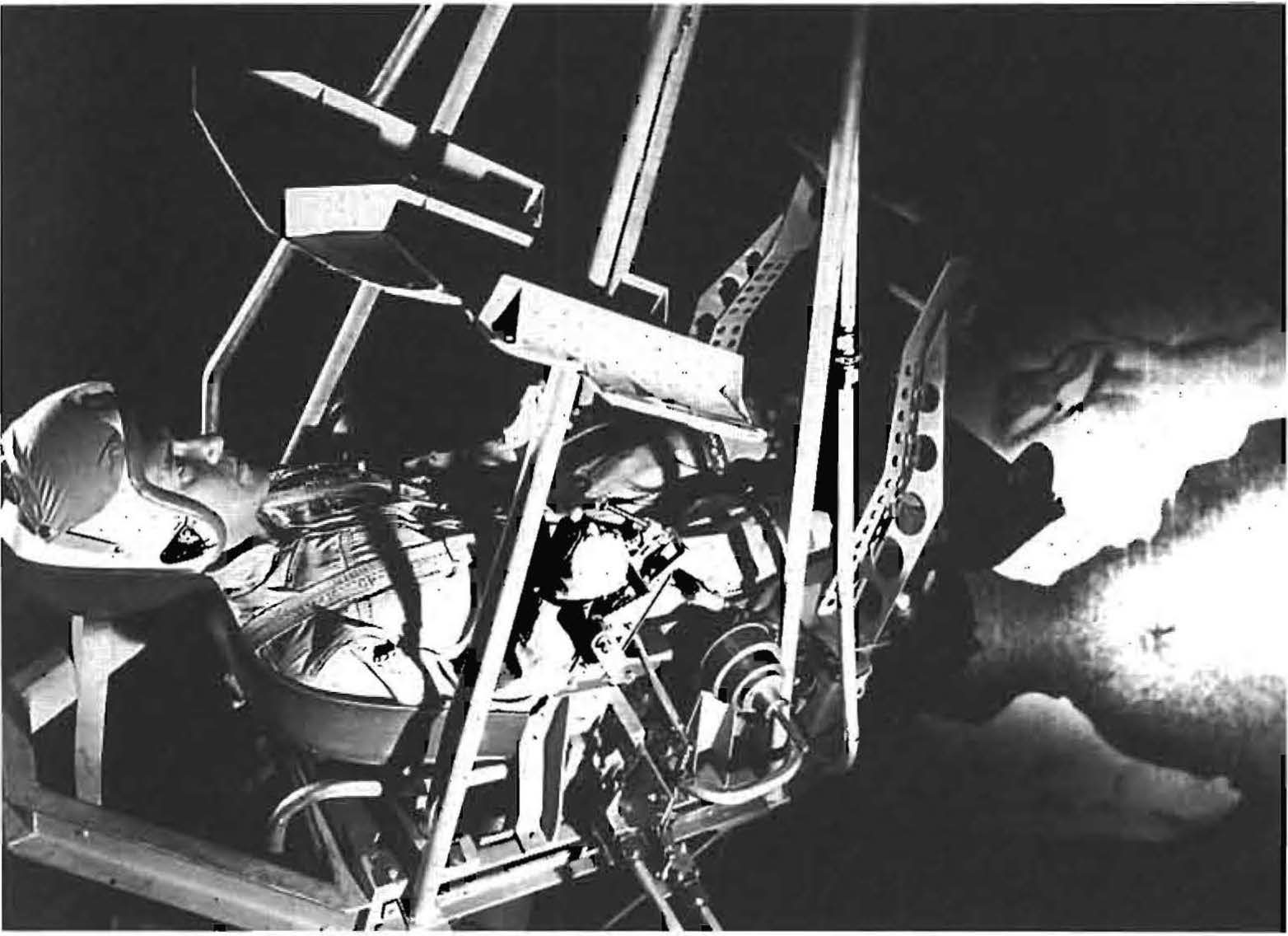

Perhaps the most impressive simulator, the whirligig called MASTIF (for Multiple Axis Space Test Inertia Facility), located at Lewis' cavernous altitude wind tunnel, was publicized far beyond its value as a training aid. Conceived in 1959 by David S. Gabriel of Lewis as a rig to test space equipment in three degrees of rotational and two degrees of linear freedom, the idea of concentric gimbaled cages was translated into hardware in the altitude wind tunnel early in 1959, when Lewis was assigned the job of testing Big Joe's attitude control system. Robert R. Miller directed the MASTIF project; Louis L. Corpas did the detail design work; and Frank Stenger developed the air-jet propulsion arrangement. Soon they had erected a tinker-toy-like rig 21 feet in diameter at its supporting yoke, capable of mounting a 3,000-pound space capsule inside its three sets of gimbals, and able to turn and tumble the whole combination in three axes simultaneously at 60 noisy revolutions per minute. An early trial revved the outer cage from zero to 50 revolutions per minute in half a turn.44

James W. Useller, another mechanical engineer at Lewis, was first to see the potential in the MASTIF, if adapted, for astronaut training. Useller and a Lewis test pilot, Joseph S. Algranti, began taking cautious rides inside the MASTIF as soon as the controls engineers could spare it in mid-1959. They set up a formal test program for about 10 pilots and physiologists who wanted to see what rolling, pitching, and yawing at different speeds and for different lengths of time would do to a man. A thorough literature search revealed some similar late-19th-century German experiments, but Useller and Algranti proceeded to confirm a condition known as ocular nystagmus, an automatic flutter of the eyeballs induced by the acceleration of angular rotation. After extensive tests, they verified a rough limit of tolerance at about 30 revolutions per minute in three axes; beyond this limit, even the most experienced pilots could expect to get sick.45

Thus, in February 1960, when the first pair of astronauts, Grissom and Shepard, arrived in Cleveland for a week's stay to test the MASTIF and their reactions to it, extensive experience had already been accumulated by other pilots. After a hard night and a frustrating morning strapped in the seat while the MASTIF was being adjusted, Shepard again stepped inside the three large gimbal cages for his second sitting but first real ride in this machine. When MASTIF finally started to spin, Shepard turned green and pressed the red "chicken switch," sounding a claxon horn as a signal to stop. To control the nausea and vertigo induced by this maniacal carousel required dogged determination. The next day Shepard - and before the end of March all the astronauts - took examination runs at 30 revolutions per minute in all three axes and quickly learned, by using the hand controller, to activate nitrogen reaction motor brakes, to halt their rotation and bring themselves to a stop while the cages continued to spin. The confidence gained from this experience was invaluable, but one series on the MASTIF was enough. Reporters who watched a demonstration by Carpenter were vivid in their descriptions of the piercing scream, multicolored cages, and extraordinary contortions of MASTIF, billing it the ultimate in wild carnival rides.46

Far more important and critical was the second phase of the Johnsville centrifuge program, which began in mid-April to test much of the McDonnell hardware, including the couch and hand controller, instrument panel and full pressure suit, and the astronauts' responses to the dynamic simulation of the g profiles. An STG status report for April listed eight multiplex objectives of the ongoing centrifuge training program: (1) to test the retention by the astronaut of the straining technique and other skills developed in the August program; (2) to familiarize the astronauts with straining under reduced pressure; (3) to familiarize the astronauts with performing at high g levels in an inflated pressure suit; (4) to evaluate the couch manufactured by McDonnell Aircraft; (5) to evaluate the handcontroller developed by McDonnell; (6) to test proposed voice procedures under acceleration and reduced pressure; (7) to rehearse and evaluate the feasibility of a two-hour countdown period following astronaut insertion; and (8) to provide initial experience with Redstone acceleration patterns.47

With over 120 controls at his glove tips, including about 55 electrical switches, 30 fuses, and 35 mechanical levers, the astronaut had to learn a great deal regarding the monitoring and operation of these points of contact with his machine. From the prime contractor came a series of operating and maintenance manuals entitled "Service Engineering Department Reports," or "SEDRs" (pronounced "cedars"). The indoctrination manual had been replaced by a familiarization manual in the fall of 1959, and this in turn was replaced at the beginning of 1960 by SEDR No. 109, called the "Astronauts' Handbook." Although the first capsule maintenance manual, SEDR No. 108, was not available until mid-year, it was not badly needed until the mass move to the Cape at that time.

The "Astronauts' Handbook" set forth operating procedures in three sections: normal, emergency, and trouble-shooting activities. The checklist for procedures envisioned in a normal orbital mission at that time included 130 items expected of the astronaut, 69 of which were part of an extensive preflight interior inspection. Under emergency operations procedures, 156 items were listed as possible pilot actions in case of equipment malfunctions. The five phases of the mission - launch, orbit, reentry, descent, and landing - each required special responses to emergencies arising during that portion of the mission. Finally, the mechanics of five major subsystems of the capsule were outlined in the trouble-shooting section and then condensed into checklists for the reaction and environmental control systems and for the electrical and communication systems. The attitude stabilization and control system checklist was promised but was not yet available.48

As McDonnell technical writers prepared and revised the "Astronauts' Handbook," STG's operational plans were becoming systematized through concurrent revisions of its "General Systems Information Document." Lewis R. Fisher, Donald D. Arabian, William M. Bland, Jr., and Sigurd A. Sjoberg first published this basic guide as "Project Mercury Working Paper No. 118" in March 1960 and revised it twice within the next year. They outlined the general plans for the Mercury-Atlas and Mercury-Redstone missions, including overall test objectives, flight plans, capsule design criteria, description of the capsule and systems, and the general operational plan from prelaunch phase through recovery. Specific mission directives were based on this format, and the authors of most later working papers presupposed a familiarity with "Working Paper No. 118."49

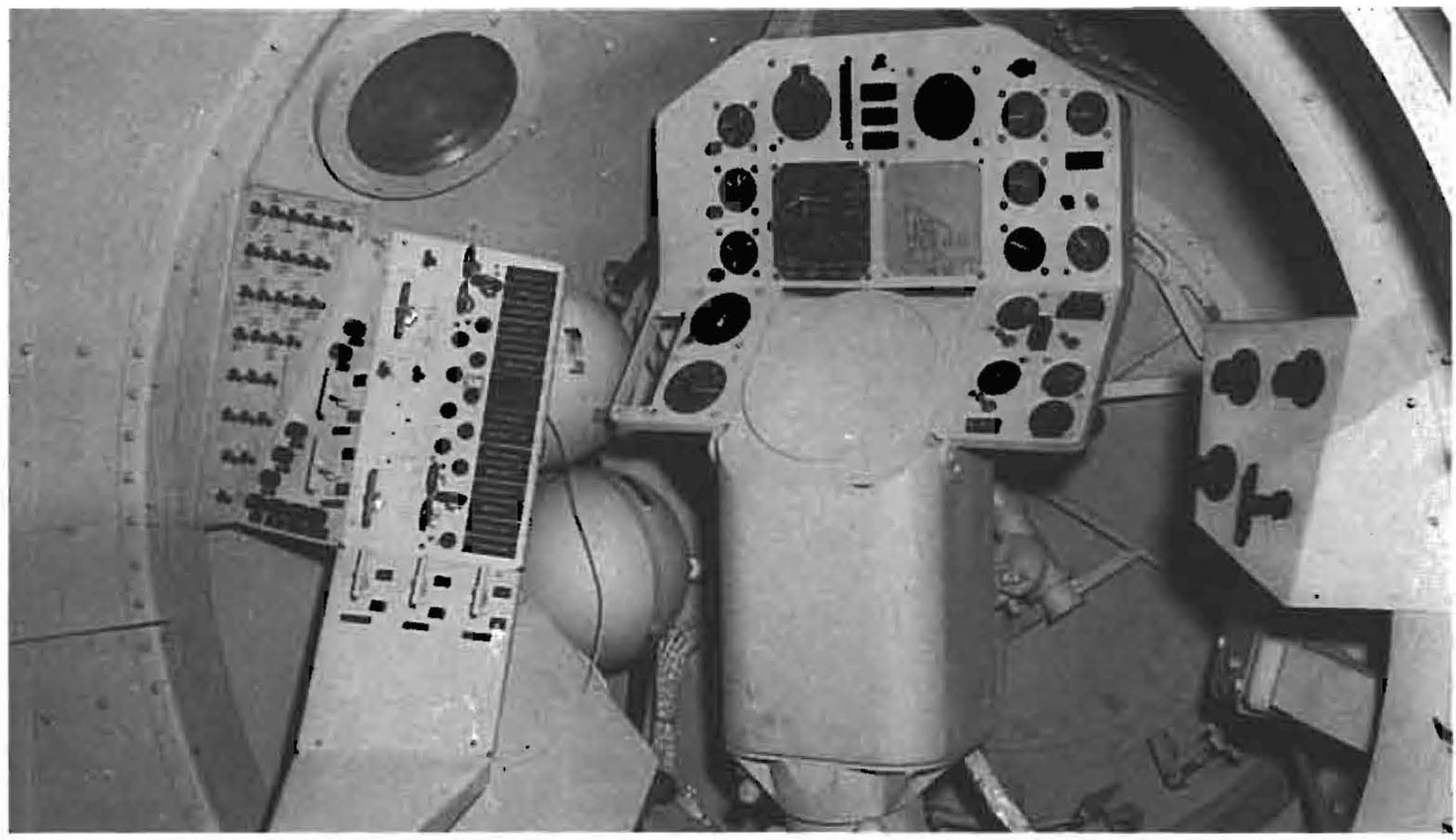

While John Glenn and Walter Schirra studied the interrelations of the pressurized suit and the cockpit layout,McDonnell design engineers rearranged the Mercury control panel to place all controls in a U-shaped pattern around either side and below the instruments. When an astronaut's suit was inflated, he could reach the right side and bottom of the panel with his right hand, and his left hand could reach the left side and bottom, but the center and top of the panel were inaccessible. Since Mercury gloves were thicker and heavier than those on flying suits, all controls had to be positive in operation, including guards for pushbuttons and with key handles and pull rings designed for a good grip and the application of considerable force, up to 50 pounds in some cases.

In their efforts to integrate man and-machine, psychologists Jones and Voas, among others, had shown by late spring 1960 how the reliability of Mercury could be increased by the use of man's flexibility. Using the pilot as a trouble-shooter engineer in many cases could make the difference between mission failure and success. Conversely, as man's limitations became more precisely known in relation to the equipment to be used, correspondingly higher standards for the automatic systems, particularly the attitude stabilization controls, were introduced. Voas later expressed a new consensus when he said:

The astronaut's primary job is to control the vehicle. The astronaut is not a mere passenger, but an active controller of the vehicle who performs an important and complex task which is basic to the total reliability of the mission.

System flexibility is increased by provision for the use of more than one of these [attitude control mode] systems at a time. Since the automatic reaction jets and the manual reaction jets are completely independent, it is possible for the man to exercise control through the manual jets while the auto-pilot is exercising control through the automatic jets. One occasion for use of both control systems would be in maneuvering in orbit when the astronaut desires to let the autopilot control two axes such as roll and pitch while he takes control in yaw.50

Meanwhile Jones and the human factors engineers at McDonnell were determining more ways in which man could back up other automatic malfunctions through their "failure task analysis." Using the failure mode predictions from the design engineers' work on the reliability program, they elaborated "in detail the probable sensory output characteristics of the failure, the corrective responses required by the astronaut or ground monitor, and the failure effect."51

Contrast in Mercury panel and console arrangement: the instrument positions in early 1959.

The panels as used in Glenn's orbital flight, Feb. 20, 1962.

Jones' human-factors team worked closely with McDonnell's Mercury reliability experts, Walter A. Harmon and Eugene A. Kunznick. They in turn allied themselves with another McDonnell crew employed on a special check of the Mercury reliability program instigated by NASA Headquarters. Programmers at McDonnell coded on punch cards all probable systemic failures; by June 1960 they had assembled massive computer printouts that detailed corrective actions an astronaut could take in case the robots should go wrong. They found that over a third of such failures would not show up on instruments or through warning lights, but could be detected through symptoms presenting unusual sights, sounds, smells, or vibrations. As many as 18 different failures, however, might show the same set of multiple cues, so the work of categorizing and organizing these data required another full year. Preliminary results from these cooperative studies helped early to isolate malfunctions that needed new indicators, to rank the frequency of instrument use, and to shape the training program. Efforts to predict the total system reliability by this evaluation intensified the debate over the "numbers game."52

Looking Over Mercury and Beyond

In March and April 1960, NASA scored two spectacular triumphs by using the Air Force's Thor-Able booster combination to launch Pioneer V and Tiros I. The former was a highly successful instrumented probe to explore the space between the orbits of Earth and Venus. Launched on March 11, Pioneer V established a new telecommunications record of 22.5 million miles by the end of June and returned a bonanza of data on solar flares, particle energies and distribution, and magnetic field phenomena in translunar space. The initial Tiros weather satellite, sent up on April 1, transmitted the first global cloud-coverage photographs from a circular orbit 450 miles high, thereby inaugurating a new age for meteorology. The request for implementation of NASA's 10-year plan presented to Congress on January 20 seemed off to a good start. An extensive congressional "Review of the Space Program" put Mercury, even in the context of NASA's present programs, in perspective as a relatively minor part of the civilian space agency's activities. In terms of NASA's plans for the future or of the total military-civilian space program already in action, Project Mercury was hardly more than "an important first step in our manned exploration of space."53

Through the winter and spring of 1960, the big event toward which Mercury watchers looked with most anticipation was the launch of the first Atlas vehicle topped by a McDonnell capsule. Immediately after Big Joe, Gilruth had requested the Ballistic Missile Division to fly another Atlas along a Big Joe-type trajectory to qualify the McDonnell capsule for launch and reentry from a circular orbit roughly 105 miles high. At the beginning of 1960, it still had looked as though this could be accomplished by the end of May. A semifinal Defense Department operations plan outlining the support tasks of a dozen different military commands was under intensive study during this period. Serious reappraisals of schedule requirements and alternatives were underway in many areas, most of which threatened to delay the start of the qualification flight. By the end of January it was obvious that the payload, McDonnell's capsule No. 6, for the first Mercury-Atlas launch (MA-1) could not be ready soon enough.54

The bottleneck was the production line. Back in October 1959, when a letter amendment to the prime contract for six additional Mercury capsules was being processed, McDonnell had estimated it could deliver capsule No. 1 by the end of November. To be sure, this would be a stripped model suitable only for an off-the-pad or beach-abort mission, but at that time it looked as if the firing date for this first qualification test could be set for the last day of 1959. It then seemed that capsule No. 2, allocated to the first Mercury-Redstone flight, also could be delivered before the end of the year and shot about March 20, 1960. The sixth capsule, farther down McDonnell's production line, originally was allotted to the first Mercury-Atlas flight. It was barely framed, but McDonnell had hoped to deliver it by the end of February for a tentative launch date in mid-May. While STG was immersed in the Little Joe program, however, the production managers at McDonnell became aware that actual final assembly of the first capsules and equipment would take far more time than anticipated. On November 3, 1959, Sherwood L. Butler, the procurement officer at Langley, had notified NASA Headquarters that capsules Nos. 1 and 2 each would be delayed a month; No. 6 might be expected by the end of February.55

What, precisely, was causing these delays? Logan T. MacMillan, Edward M. Flesh, Yardley, and Dubusker of McDonnell felt constrained to answer as the pressure for delivery increased - as did certain conditions that obviously needed to be corrected. Incorporating the smallest changes during the final assembly of the first six capsules required many hours of disassembly, reassembly, and rechecking. Only one or two men at most could work in the confined space of the pressure vessel's interior, and rising standards of quality control imposed by McDonnell, STG, and resident Navy inspectors required much reworking.

For example, on the first shift on January 6, 1960, J. E. Miller, the McDonnell inspector on the floor at the time, logged in his record book a local cause of delay:

Insp. discontinued all work on Cap. #1 this A.M. until the filthy condition of the capsule was cleaned up. A meeting of Prod. Supervision was called by Insp. & Engr., was asked to set [sic] in. Quality control was main subject & all agreed to extend more effort toward better quality control although Prod. did not think they could do much better than what was already being done.56

The next week at a capsule coordination meeting in St. Louis, Purser and MacMillan, Yardley and Faget persuaded Robert Gilruth to save MA-1 by swapping capsule No. 6 for capsule No. 4, which had been scheduled for a static firing on the Redstone. Number 4 should be tidied up as quickly as possible and shipped to Langley by the end of the month. Only a structural shell, this first delivered piece of production hardware did include the exterior shingles, heatshield, landing and recovery gear, missile adapter-ring, retropackage and straps, with dummy retros and live posigrades. STG undertook to install Big Joe-type instrumentation and sequencing for its rescheduled use on the first Mercury-Atlas flight. The plan was to return the capsule to McDonnell by April1 for final shingle fittings and adapter matings, then ship the completed capsule to the Cape by mid-April. At the same time it was decided to eliminate the flotation bags, which had proved to be too delicate to last long in the open ocean, from all capsules and to keep the configuration of capsules Nos. 5 and 7 unchanged in hope of making possible an earlier manned shot. Problems with the afterbody shingles and with the erosion of the window by the blast of the escape rocket were among a number left unsettled.57

As costs of solutions to these kinds of technological and training problems rose, NASA administrators appeared more frequently before Congressional committees and admitted their growing concern with manned space flight, as opposed to other space activities. T. Keith Glennan requested $23 million supplemental appropriation to the fiscal 1960 NASA budget of $500.6 million and justified $19 million of that extra sum on the basis of the urgent technological demands of Project Mercury. "It would be no exaggeration to say that the immediate focus of the U.S. space program is upon this project," stated Glennan.58

Management Learns Its Limits

The astronauts were not alone in their need to become in some sense machine-rated. The managers of Mercury, both the civil servants and the contractors, had found truth in the maxim of industrial management that short-term estimates of accomplishment are nearly always overestimated. Mercury, like virtually all contractual development programs, entailed inherent technical and administrative difficulties impossible to foresee. A corollary to the rule of short-term estimates, namely that long-term predictions of accomplishments are very often underestimated, offered little solace at this stage of the development of Project Mercury. In its fifth status report at the end of January 1960, the Space Task Group related to Headquarters some of the lessons learned during its first year of contractual operations:

A new capsule delivery schedule has recently been indicated by McDonnell to reflect a delay in delivery of over 3 months in the early capsules. This revision was made necessary by a realistic appraisal of progress to date. Although various proposals for improving the situation have been considered, there does not seem to be any practical avenue open at this time for effecting any worthwhile change.

Because of these delays and the fact that it has not been possible to substantiate the shingle structure adequately on the ground, it has been decided to cancel the vibration program on capsule No. 4 and instead to fit this capsule with an absolute minimum of equipment and instrumentation and to fire it on an Atlas as MA-1 … at the earliest practicable date.59

Gilruth, Charles J. Donlan, and their younger associates in STG grew older rapidly during their first 15 months as a contracting agency. Gradually attaining more autonomy, the Space Task Group still expected eventually to move to Beltsville, Maryland. But in February NASA Headquarters made clear its intention not to move STG until Project Mercury was essentially completed. Relations with the Langley Research Center, STG's parent organization, improved markedly with better organizational arrangements, such as job order procedures, and with the growth of STG's own administrative staff. Close working exchanges still prevailed in many areas, especially with the Langley shopmen under Jack A. Kinzler providing technical services. But on STG's first birthday, only two out of Langley's 12 applied research divisions could still say with regard to Mercury that "there is as much to be done as has been done."60

The Pilotless Aircraft Research Division (PARD), renamed the Applied Materials and Physics Division at the end of 1959, and the Instrument Research Division were still most actively supporting Mercury.

During STG's infant year, overall Langley support amounted to well over 100 separate preliminary data releases, contributed by more than 325 professional people, and costing approximately $1.9 million of Langley's own appropriations. STG's personnel complement in January 1960 was climbing above 500; the total cost of the prime contract with McDonnell, already modified in about 120 particulars, was approaching $70 million and rising. At the same time, McDonnell estimated that more than half its total effort on Project Mercury was still in engineering development; a third of its effort was on actual production; and about 10 percent was on tooling. According to McDonnell's assistant contract manager, the overall weighted percentage of contract completion was just below 60 percent.61

The magnitude of monitoring a contract of this size was reflected in another reorganization of the Space Task Group in mid-January. Formalized in the new block chart were the personnel office under Burney H. Goodwin, a budget and finance office under J. P. Donovan, a procurement and supply office under Glenn F. Bailey, and an administrative services office under Guy W. Boswick, Jr. STG simplified its three line divisions by making James A. Chamberlin chief of its "Engineering Division" instead of the "Engineering and Contract Administration Division." Under Chamberlin, Andre J. Meyer, Jr., and Norman F. Smith served as assistant chief and executive engineer, respectively. In Faget's Flight Systems Division, Robert O. Piland and J. T. Markley were confirmed in their posts as assistant chief and executive engineer.

At this time Faget unofficially set Robert Piland to work considering advanced vehicles suitable for a circumlunar space flight. This soft-spoken Virginian had turned from mathematics to aeronautical engineering in 1947 and had served as technical assistant to James T. Killian and the President's Science Advisory Committee during 1958. Technically able and politically experienced, Piland directed the circumlunar pilot studies for four months before authorization for an advanced vehicle team on May 25, 1960, formally added eight other senior STG engineers to look to the future beyond Mercury.62

Robert Piland also learned something from his older brother, Joseph V. Piland, assistant head of the contracts and scheduling office, who had evolved from a mechanical engineer into a contract administrator. Joseph Piland was instrumental in smoothing STG's formal relationships with its industrial contractors. His counterpart in McDonnell's organization was C. F. Picard, and together they had now to supervise over 50 subcontractors and over 5,000 sub-subcontractors.

Charles Mathews' Operations Division was in a state of flux as he and Walter C. Williams shuffled men and positions in preparation for manned operations. Christopher C. Kraft, Jr., and Chris C. Critzos stayed put, while G. Merritt Preston went to the Cape and Scott H. Simpkinson was sent to St. Louis to help expedite matters at McDonnell. Other names on the STG organization chart of January 11, 1960, filled staff positions alongside Purser, Kenneth S. Kleinknecht, and Martin A. Byrnes. Another assistant to the director was Raymond L. Zavasky; heading the technical services liaison with Langley was Kinzler. The military officers originally assigned to STG as liaison remained aboard and active. They were Colonel Keith G. Lindell of the Air Force, who doubled as head of the astronaut and training section; Lieutenant Colonel Martin L. Raines of the Army; and Commander Paul L. Havenstein of the Navy. Even Langley Research Center, across the field, had its liaison man on STG's staff: W. Kemble Johnson.63

Beginning in January 1960, plans were made to integrate the astronaut with a flight-control team as well as with his machine. Team training of the remote-site ground crews required an extensive familiarization and orientation program. The initial proposal for training these teams began with an admonition:

It is essential that the training of the flight control personnel be closely integrated with that of the astronaut's. As long as the astronaut is conscious all ground commands must be executed through or with the concurrence of the pilot. To be effective, the pilot and the ground crew must work as a closely knit team. An efficient system is dependent upon adequate team training and development of mutual confidence.64