Saturn the Giant

By WERNHER VON BRAUN

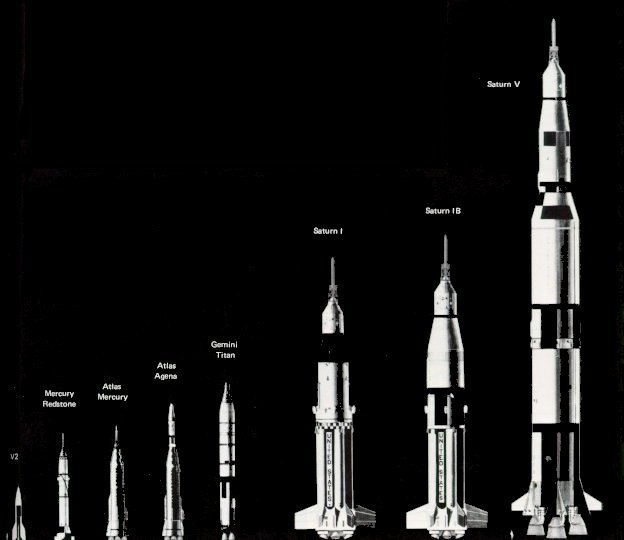

With the beep-beep-beep of Sputnik on October 4, 1957, the Soviet Union had inaugurated the Space Age. It had also presented American planners with the painful realization that there was no launch vehicle in the U.S. stable capable of orbiting anything approaching Sputnik’s weight.

Responding to a proposal submitted by the Army Ballistic Missile Agency, the Department of Defense was in just the right mood to authorize ABMA to develop a 1,500,000-pound-thrust booster. That unprecedented thrust was to be generated by clustering eight S-3D Rocketdyne engines used in the Jupiter and Thor missiles. The tankage for the kerosene and liquid oxygen was also to be clustered to make best use of tools and fixtures availabie from the Redstone and Jupiter programs. The program was named “Saturn” simply because Saturn was the next outer planet after Jupiter in the solar system.

Gen. John B. Medaris, commander of ABMA and my boss, felt that for a good design job on the booster it was necessary for us also to study suitable upper stages for the Saturn. On November 18, 1959, Saturn was transferred to the new National Aeronautics and Space Administration. NASA promptly appointed a committee to settle the upper-stage selection for Saturn. It was chaired by Dr. Abe Silverstein who, as associate director of NASA’s Lewis Center in Cleveland, had spent years exploring liquid hydrogen as a rocket fuel. As a result of this work the Air Force had let a contract with Pratt & Whitney for the development of a small 15,000-pound-thrust liquid hydrogen/liquid oxygen engine, two of which were to power a new “Centaur” top stage for the Air Force’s Atlas. Abe was on solid ground when he succeeded in persuading his committee to swallow its scruples about the risks of the new fuel and go to high-power liquid hydrogen for the upper stage of Saturn.

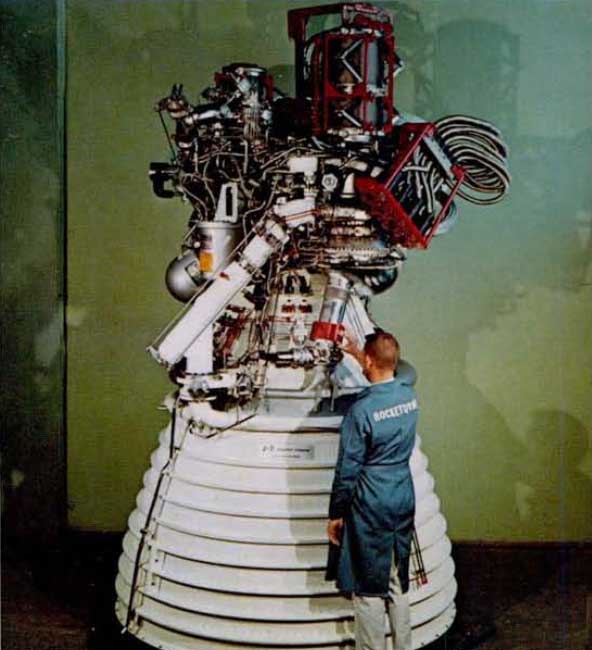

In the wake of Gagarin’s first orbital flight on April 12, 1961, Saturn gained increased importance. Nevertheless, when the first static test of the booster with all eight engines was about to begin, at least one skeptical witness predicted a tragic ending of “Cluster’s last stand”. Doubts about the feasibility of clustering eight highly complex engines had indeed motivated funding for two new engine developments. One was in essence an uprating and simplification effort on the S-3D, and it led to the 188,000-pound-thrust H-1 engine. The other aimed at a very powerful new engine called F-1, which was to produce a full 1.5-million-pound thrust in a single barrel. Both contracts went to Rocketdyne.

Following up on the recommendation of the Silverstein committee, NASA awarded a contract to the Douglas Aircraft Company for the development of a second stage for Saturn that became known as S-IV. It was to be powered by six Centaur engines. On September 8, 1960, President Eisenhower came to Huntsville to dedicate the new Center, named after Gen. Georce C. Marshall. It was to become the focal point for NASA’s new large launch vehicles, and I was appointed as its first director.

DETERMINING SATURN’s CONFIGURATION

The first launch of the Saturn booster was still five months away when, on May 25, 1961, President John F. Kennedy proposed that the United States commit itself to land a man on the Moon “in this decade”. For this ambitious task a launch vehicle far more powerful than our eight-engine Saturn would be needed. To determine its exact power requirements, a selection had to be made from among three operational concepts for a manned voyage to the Moon: direct ascent, Earth orbit rendezvous (EOR), and lunar orbit rendezvous (LOR).

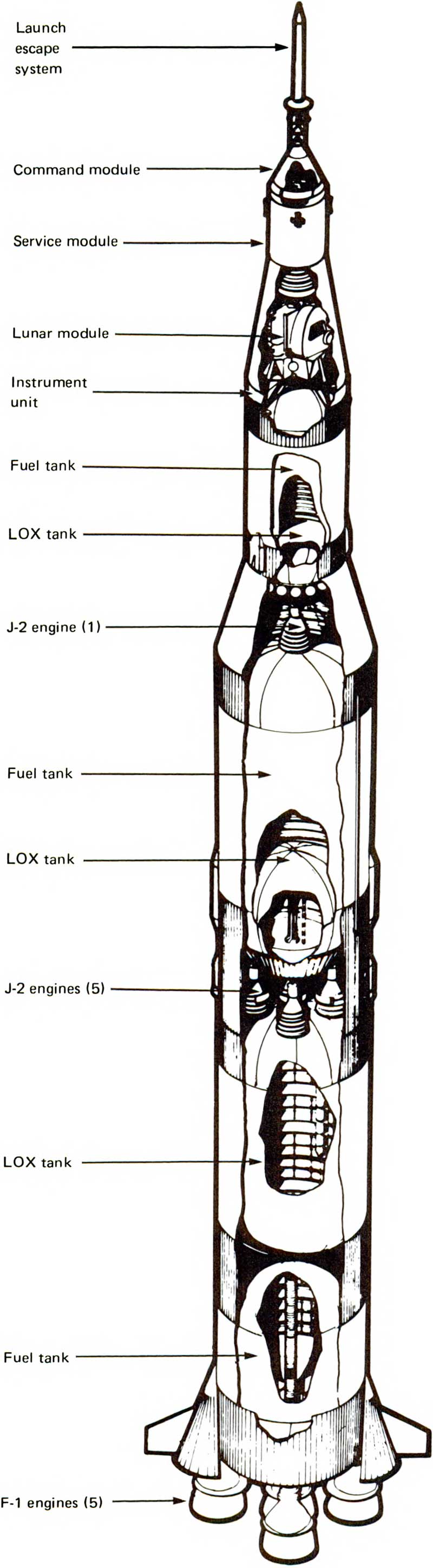

With direct ascent, the entire spacecraft would soft-land on the Moon carrying enough propellants to fly back to Earth. Weight and performance studies showed that this would require a launch vehicle of a lift-off thrust of 12 million pounds, furnished by eight F-1 engines. We called this hypothetical launch vehicle Nova. The EOR mode envisioned two somewhat smaller rockets that were to rendezvous in Earth orbit where their payloads would be combined. In the LOR mode a single rocket would launch a payload consisting of a separable spacecraft toward the Moon, where an onboard propulsion unit would ease it into orbit. A two-stage lunar module (LM) would then detach itself from the orbiting section and descend to the lunar surface. Its upper stage would return to the circumlunar orbit for rendezvous with the orbiting section. In a second burst of power, the propulsion unit would finally drive the reentry element with its crew out of lunar orbit and back to Earth.

As all the world knows, the LOR mode was ultimately selected. But even after its adoption, the number of F-1 engines to be used in the first stage of the Moon rocket remained unresolved for quite a while. H.H. Koelle, who ran our Project Planning Group at Marshall, had worked out detailed studies of a configuration called Saturn IV with four F-l’s, and another called Saturn V with five F-l’s in its first stage. Uncertainty about LM weight and about propulsion performance of the still untested F-1 and upper-stage engines, combined with a desire to leave a margin for growth, finally led us to the choice of the Saturn V configuration.

Despite the higher power offered by liquid hydrogen, Koelle’s studies indicated that little would be gained by using it in the first stage also, where it would have needed disproportionately large tanks. (Liquid hydrogen is only one twelfth as dense as kerosene, so a much larger tank volume would have been required.) In all multistage rockets the upper stages are lighter than the lower ones. Thus heavier but less energetic kerosene in the first stage, in combination with lighter but more powerful hydrogen in the upper stages, made possible a better launch-vehicle configuration.

Saturn V, as it emerged from the studies, would consist of three stages-all brand new. The first one, burning kerosene and oxygen, would be powered by five F-1 engines. We called it S-IC. The second stage, S-11, would need about a million pounds of thrust and, if also powered by five engines, would call for the development of new 200,000-pound hydrogen-oxygen engines. A single engine of this thrust would just be right to power the third stage. The Saturn l’s S-IV second stage was clearly not powerful enough to serve as the Saturn’s third one. A much larger tankage and at least thirteen of Pratt & Whitney’s little LR-10 engines would be required; this did not appear very attractive.

When bids for the new J-2 engine were solicited, Pratt & Whitney with its ample liquid-hydrogen experience was a strong contender. But when all the points in the sternly controlled bidding procedure were counted, North American’s Rocketdyne Division won again.

North American had been involved in the development of liquid fuel rocket engines since the immediate postwar years and the Navajo long range ramjet program. The engines it developed for the Navajo booster and their offspring later found their way into the Atlas, Redstone, Thor, and Jupiter programs. For the testing of these engines NAA’s Rocketdyne Division had acquired a boulder-strewn area high in the Santa Susana mountains, north of Los Angeles, that had previously served as rugged background for many a Western movie. The Santa Susana facility would henceforth serve not only for the development of the new J-2 engine, but also for short duration “battleship" testing of the five-engine cluster of these engines powering the S-11 stage. (Safety and noise considerations ruled out the use of Santa Susana for the 1.5-million-pound-thrust F-1 engine. Test stands for its development were therefore set up in the Mojave desert, adjacent to Edwards Air Force Base.)

CHOOSING THE BUILDERS

How many prime contractors, we wondered, should NASA bring in for the development of the Saturn V? Just one, or one per stage? How about the Instrument Unit that was to house the rocket’s inertial-guidance system, its digital computer, and an assortment of radio command and telemetry functions? Who would do the overall systems engineering and monitor the intricate interface between the huge rocket and the complex propellant-loading and launching facilities at Cape Canaveral? Where would the various stages be static-tested?

Understandably, the entire aerospace industry was attracted by both the financial value and the technological challenge of Saturn V. To give the entire plum to a single contractor would have left all others unhappy. More important, Saturn V needed the very best engineering and management talent the industry could muster. By breaking up the parcel into several pieces, more top people could be brought to bear on the program.

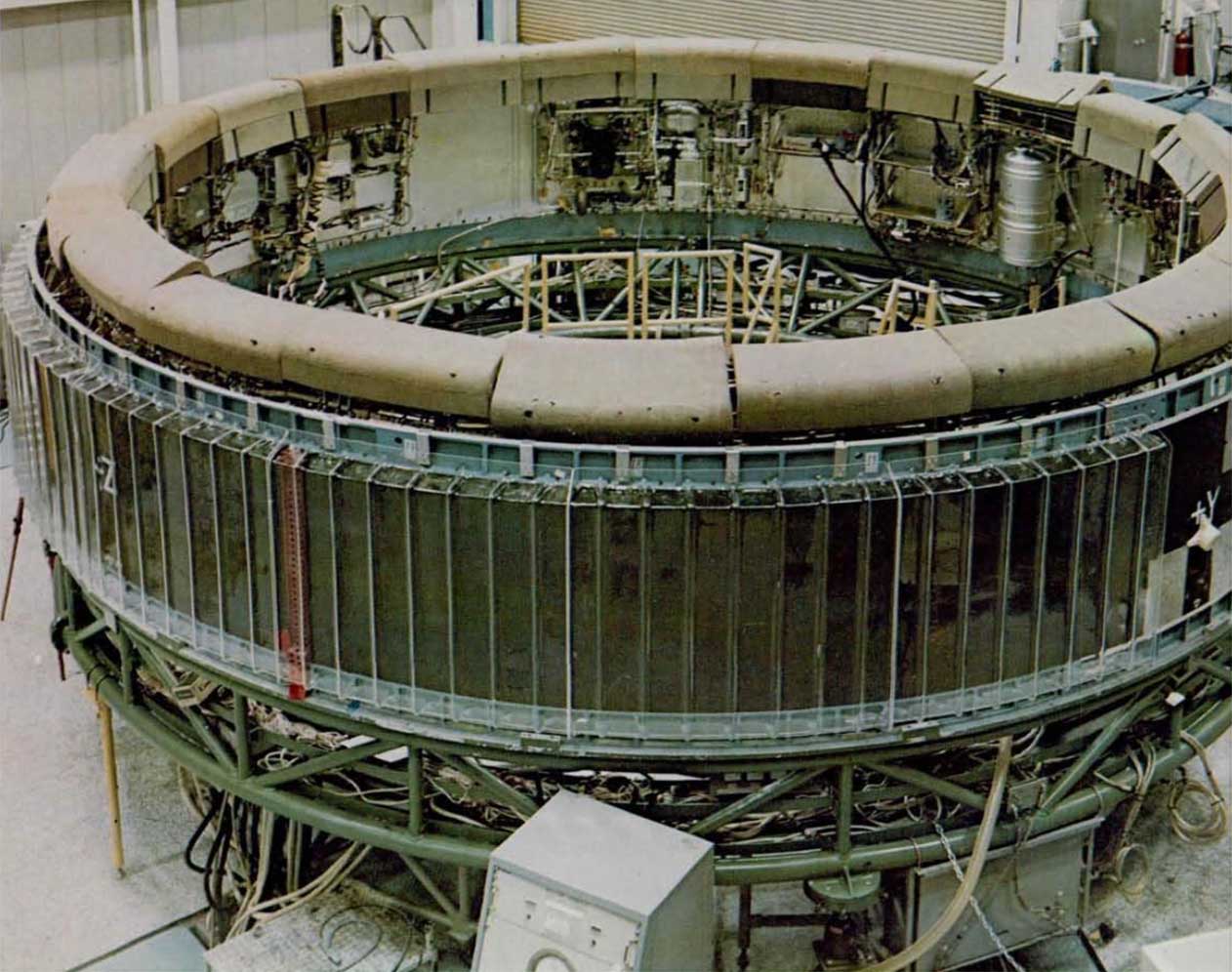

The Boeing Company was the successful bidder on the first stage (S-IC); North American Aviation won the second stage (S-11), and Douclas Aircraft fell heir to the Saturn V’s third stage (S-IVB). Systems engineering and overall responsibility for the Saturn V development was assigned to the Marshall Space Flight Center. The inertial-guidance system had emerged from a Marshall in-house development, and as it had to be located close to other elements of the big rocket’s central nervous system, it was only logical to develop the Instrument Unit (IU) to house this electronic gear as a Marshall in-house project. IU flight units were subsequently produced by IBM, which had developed the launch-vehicle computer.

Uniquely tight procurement procedures introduced by NASA Administrator Jim Webb made it possible to acquire billions of dollars’ worth of exotic hardware and facilities without overrunning initial cost estimates and without the slightest hint of procurement irregularity. Before it could issue a request for bids, the contracting NASA Center had to prepare a detailed procurement plan that required the Administrator’s personal approval, and that could not be changed thereafter. It had to include a point-scoring system in which evaluation criteria - technical merits, cost, skill availability, prior experience, etc. - were given specific weighting factors. Business and technical criteria were evaluated by separate teams not permitted to know the other’s rankings. The total matrix was then assembled by a Source Evaluation Board that gave a complete presentation of all bids and their scoring results to the three top men in the agency, who themselves chose the winner. There was simply no room for arbitrariness or irregularity in such a system.

The tremendous increase in contracts needed for the Saturn V program required a reorganization of the Marshall Space Flight Center. Most of our resources had been spent in-house, and our contracts had either been let to support contractors or to producers of our developed products. Now 90 percent of our budget was spent in industry, much of it on complicated assignments which included design, manufacture, and testing. So on September 1, 1963, I announced that Marshall would henceforth consist of two major elements, one to be called Research and Development Operations, the other Industrial Operations. Most of my old R&D associates then became a sort of architect’s staff keeping an eye on the integrity of the structure called Saturn V, and the other group funded and supervised the industrial contractors.

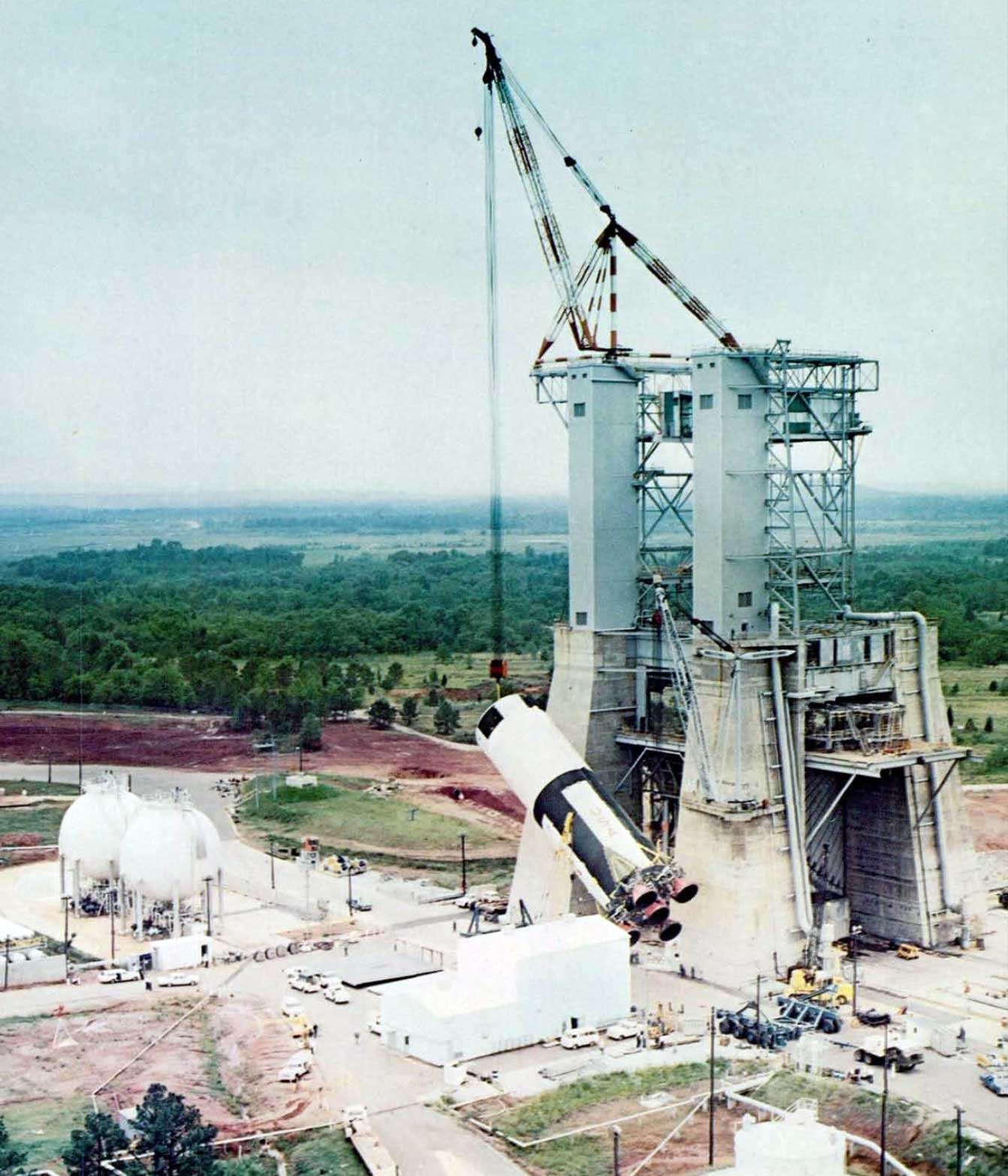

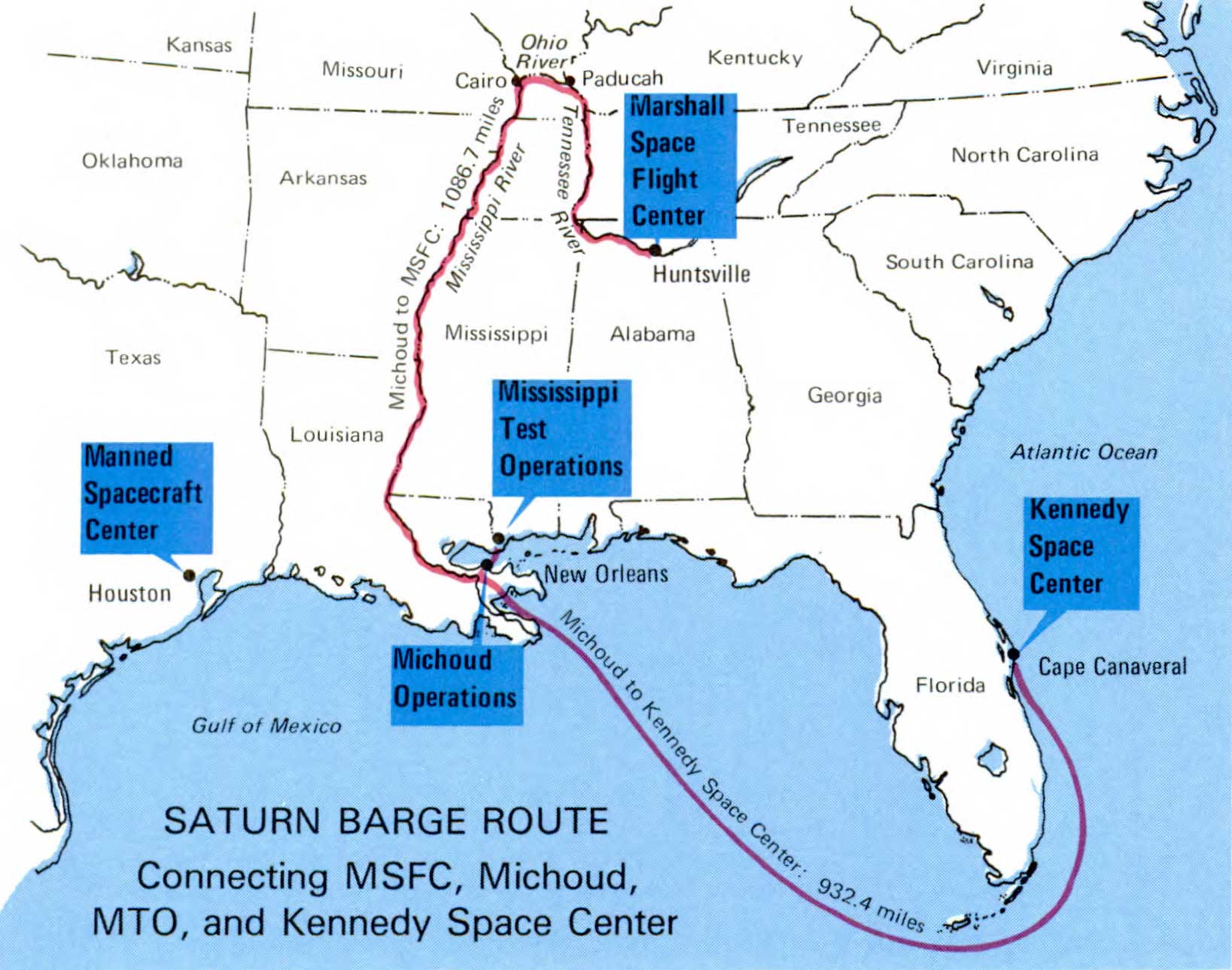

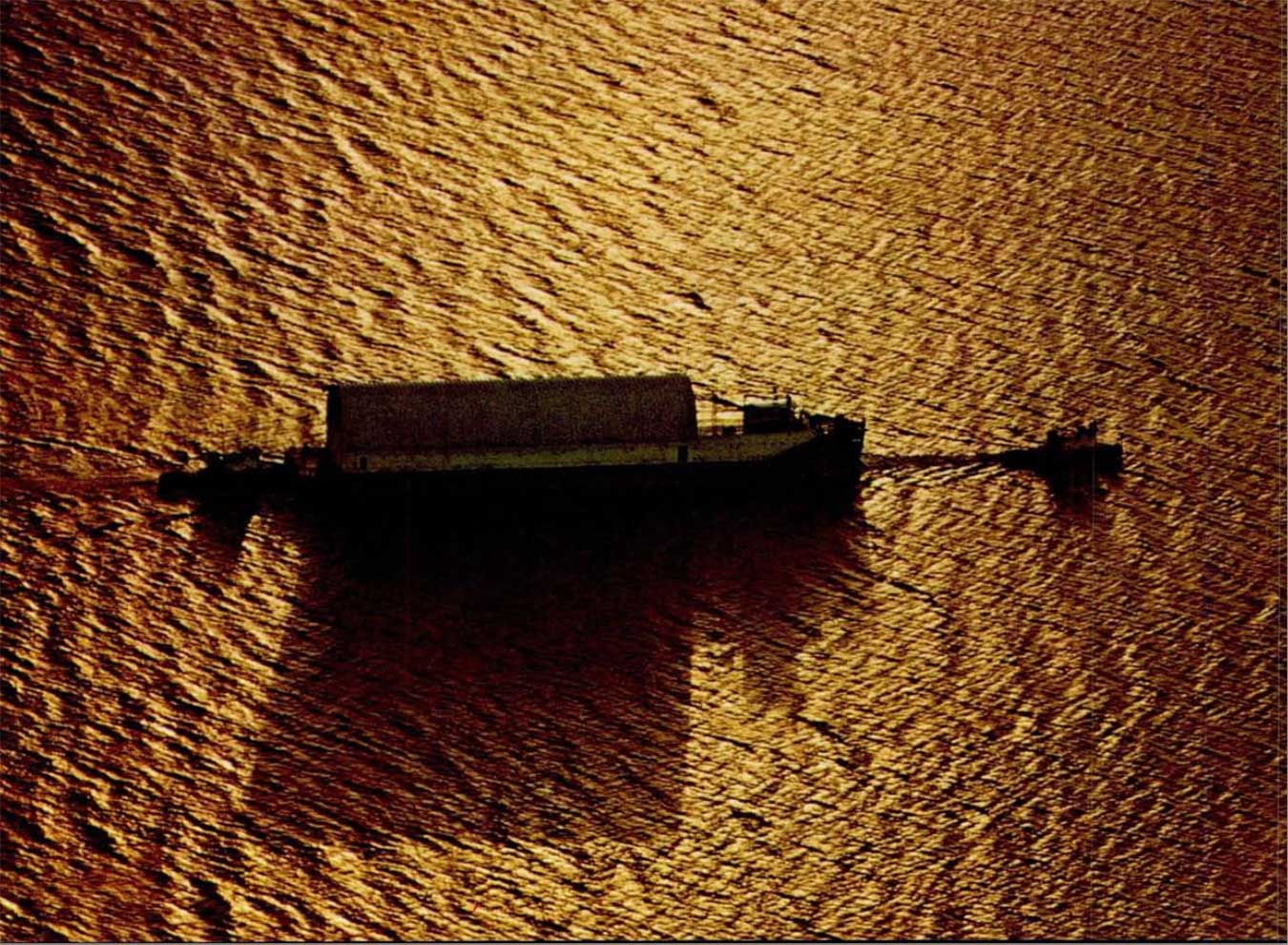

That same year Dr. George Mueller had taken over as NASA’s Associate Administrator for Manned Space Flight. He brought with him Air Force Maj. Gen. Samuel Phillips, who had served as program manager for Minuteman, and now became Apollo Program Director at NASA Headquarters. Both men successfully shaped the three NASA Centers involved in the lunar-landing program into a team. I was particularly fortunate in that Sam Phillips persuaded his old friend and associate Col. (later Maj. Gen.) Edwin O’Connor to assume the directorship of Marshall’s Industrial Operations. On September 7, 1961, NASA had taken over the Michoud Ordnance plant at New Orleans. The cavernous plant - 46 acres under one roof - was assigned to Chrysler and Boeing to set up production for the first stages of Saturn I and Saturn V. In October 1961 an area of 13,350 acres in Hancock County, Miss., was acquired. Huge test stands were erected there for the static testing, of Saturn V’s first and second stages. Shipment of the oversize stages between Huntsville, Michoud, the Mississippi Test Facility, the two California contractors, and the Kennedy Space Center in Florida required barges and seagoing ships. Soon Marshall found itself running a small fleet that included the barges Palaemon, Orion, and Promise. For shipments through the Panama Canal we used the USNS Point Barrow and the SS Steel Executive. For rapid transport we had two converted Stratocruisers at our disposal with the descriptive names “Pregnant Guppy” and “Super Guppy”. Their bulbous bodies could accommodate cargo up to the size of an S-IVB stage.

AN ALL-UP TEST FOR THE FIRST FLIGHT

In 1964 George Mueller visited Marshall and casually introduced us to his philosophy of “all-up” testing. To the conservative breed of old rocketeers who had learned the hard way that it never seemed to pay to introduce more than one major change between flight tests, George’s ideas had an unrealistic ring. Instead of beginning with a ballasted first-stage flight as in the Saturn I program, adding a live second stage only after the first stage had proven its flightworthiness, his “all-up” concept was startling. It meant nothing less than that the very first flight would be conducted with all three live stages of the giant Saturn V. Moreover, in order to maximize the payoff of that first flight, George said it should carry a live Apollo command and service module as payload. The entire flight should be carried through a sophisticated trajectory that would permit the command module to reenter the atmosphere under conditions simulating a return from the Moon.

It sounded reckless, but George Mueller’s reasoning was impeccable. Water ballast in lieu of a second and third stage would require much less tank volume than liquid-hydrogen-fueled stages, so that a rocket tested with only a live first stage would be much shorter than the final configuration. Its aerodynamic shape and its body dynamics would thus not be representative. Filling the ballast tanks with liquid hydrogen? Fine, but then why not burn it as a bonus experiment? And so the arguments went on until George in the end prevailed.

In retrospect it is clear that without all-up testing the first manned lunar landing could not have taken place as early as 1969. Before Mueller joined the program, it had been decided that a total of about 20 sets of Apollo spacecraft and Saturn V rockets would be needed. Clearly, at least ten unmanned flights with the huge new rocket would be required before anyone would muster the courage to launch a crew with it. (Even ten would be a far smaller number than the unmanned launches of Redstones, Atlases, and Titans that had preceded the first manned Mercury and Gemini flights.) The first manned Apollo flights would be limited to low Earth orbits. Gradually we would inch our way closer to the Moon, and flight no. 17, perhaps, would bring the first lunar landing. That would give us a reserve of three flights, just in case things did not work as planned.

Mueller changed all this, and his bold telescoping of the overall plan bore magnificent fruit: With the third Saturn V ever to be launched, Frank Borman’s Apollo 8 crew orbited the Moon on Christmas 1968, and the sixth Saturn V carried Neil Armstrong’s Apollo 11 to the first lunar landing. Even though production was whittled back to fifteen units, Saturn V’s launched a total of two unmanned and ten manned Apollo missions, plus one Skylab space station. Two uncommitted rockets went into mothballs.

But let us go back to 1962. To develop and manufacture the large S-11 and S-IVB stages, two West Coast contractors required special facilities. A new Government plant was built at Seal Beach where North American was to build the S-11. S-IVB development and manufacture was moved into a new Douglas center at Huntington Beach, while static testing went to Sacramento. The Marshall Center in Huntsville was also substantially enlarged. A huge new shop building was erected for assembly of the first three S-IC stages. A large stand was built to static-test the huge stage under the full 7,500,000-pound-thrust of its five F-1 engines. These engines generated no less than 180 million horsepower. As about 1 percent of that energy was converted into noise, neighborhood windows could be expected to break and plaster rain from ceilings if the wind was blowing from the wrong direction or the clouds were hanging low. A careful meteorological monitoring program had to be instituted to permit test runs only under favorable weather conditions.

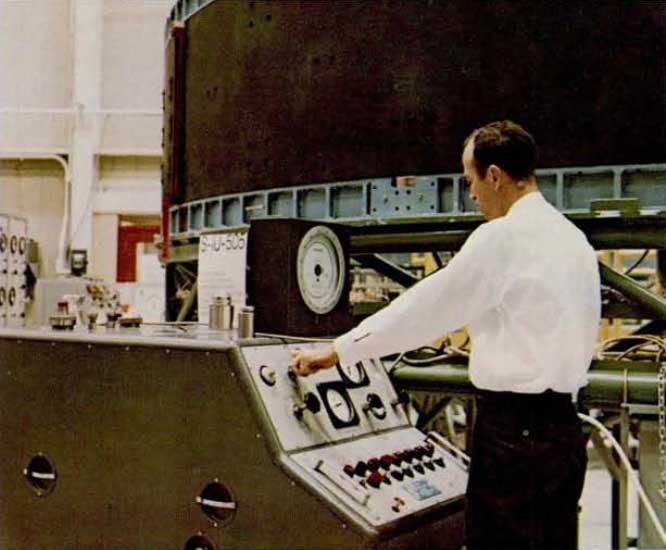

Although the most visible and audible signs of Marshall’s involvement in Saturn V development were the monstrous and noisy S-IC engines, equally important work was done in its Astrionics Laboratory. The Saturn V’s airbearing-supported inertial guidance platform was born there, along with a host of other highly sophisticated electronic devices. In the Astrionics Simulator Facility, guidance and control aspects of a complete three-stage flight of the great rocket could be electronically simulated under all sorts of operating conditions. The supersonic passage of the rocket through a high-altitude jet stream could be duplicated, for instance, or the sudden failure of one of the S-11 stage’s five engines. The simulator would faithfully display the excursions of the swivel-mounted rocket engines in response to external wind forces or unsymmetrical loss of thrust, establishing the dynamic response of the entire rocket and the resulting structural loads.

The Saturn V’s own guidance system would guide the Apollo flights not only to an interim parking orbit but all the way to translunar injection. It fed position data to the onboard digital computer, which in turn prepared and sent control signals to the hydraulic actuators that swiveled the big engines for flight-path control. As propellant consumption lightened the rocket, and as it traversed the atmosphere at subsonic and supersonic speeds, the gain settings of these control signals had to vary continuously, for proper control damping. Serving as the core of the Saturn V’s central nervous system, the computer did many other things too. It served in the computerized prelaunch checkout procedure of the great rocket, helped calibrate the telemetry transmissions, activated staging procedures, turned equipment on and off as the flight proceeded through various speed regimes, and even watched over the cooling system that stabilized the temperatures of the array of sensitive blackboxes within the IU. So although the working flight lifetime of the Saturn computer was measured in minutes, it performed many exacting duties during its short and busy life.

In planning the lunar mission, why did we plan to stop over in a parking orbit? The reason was twofold: For one, in case of a malfunction it is much easier and safer for astronauts to return from Earth orbit than from a high-speed trajectory carrying them toward the Moon. A parking orbit offers both crew and ground controllers an opportunity to give the vehicle a thorough once-over before committing it to the long voyage. Second, there is the consideration of operational flexibility. lf the launch came off at precisely the right instant, only one trajectory from the launch pad to the Moon had to be considered. But as there was always the possibility of a last-minute delay it appeared highly desirable to provide a launch window of reasonable duration. This meant not only that the launch azimuth hand to be changed, but due to Earth rotation and to orbital motion the Moon would move to a different position in the sky. A parking orbit permitted an ideal way to take up the slack: the longer a launch delay, the shorter the stay in the parking orbit. Restart of the third stage in parking orbit for translunar injection would take place at almost the same time of day regardless of launch delays. (As it happened, all but two of the manned Apollo-Saturns lifted off within tiny fractions of a second of being precisely on time. One was held for weather and the other was held because of a faulty diode in the ground-support equipment.)

Why was the big rocket so reliable? Saturn V was not overdesigned in the sense that everything was made needlessly strong and heavy. But great care was devoted to identifying the real environment in which each part was to work - and “environment” included accelerations, vibrations, stresses, fatigue loads, pressures, temperatures, humidity, corrosion, and test cycles prior to launch. Test programs were then conducted against somewhat more severe conditions than were expected. A methodology was created to assess each part with a demonstrated reliability figure, such as 0.9999998. Total rocket reliability would then be the product of all these parts reliabilities, and had to remain above the figure of 0.990, or 99 percent. Redundant parts were used whenever necessary to attain this reliability goal.

Marshall built an overall systems simulator on which all major subsystems of the three-stage rocket could be exercised together. This facility featured replicas of propellant tanks that could be loaded or unloaded, pressurized or vented, and that duplicated the pneumatic and hydraulic dynamics involved. Electrically, it simulated the complete network of the launch vehicle and its interfacing ground support equipment.

THE PERILS OF POGO

An important Marshall facility was the Dynamic Test Tower, the only place outside the Cape where the entire Saturn V vehicle could be assembled. Electrically powered shakers induced various vibrational modes in the vehicle, so that its elastic deformations and structural damping characteristics could be determined. The Dynamic Test Tower played a vital role in the speedy remedy of a problem that unexpectedly struck in the second flight of a Saturn V. Telemetry indicated that during the powered phases of all three stages a longitudinal vibration occurred, under which the rocket alternately contracted and expanded like a concertina. This “pogo” oscillation (the name derived from the child’s toy) would be felt particularly strongly in the command module.

Analysis, supported by data collected in engine tests, confirmed that the oscillation was caused by resonance coupling between the springlike elastic structure of the tankage, and the rocket engines’ propellant-feed systems. Susceptibility to pogo (a phenomenon not unknown to missile designers) had been thoroughly investigated by the Saturn stage contractors, who had certified that their respective designs would be pogo-free. It turned out that these mathematical analyses had been conducted on an inadequate data base.

Once the problem was understood, a fix was quickly found. “in sync” with the pogo oscillations, pressures in the fuel and oxidizer feed lines fluctuated wildly. lf these fluctuations could be damped by gas-filled cavities attached to the propellant lines, which would act as shock absorbers, the unacceptable oscillation excursions should be drastically reduced. Such cavities were readily available in the liquid-oxygen prevalves, whose back sides were now filled with pressurized helium gas tapped off the high-pressure control system. After a few weeks of hectic activity, a pogo-free Saturn flight no. 3 successfully boosted the Apollo 8 crew to their Christmas flight in lunar orbit.

ARTIFICIAL STORMS AT THE ARM FARM

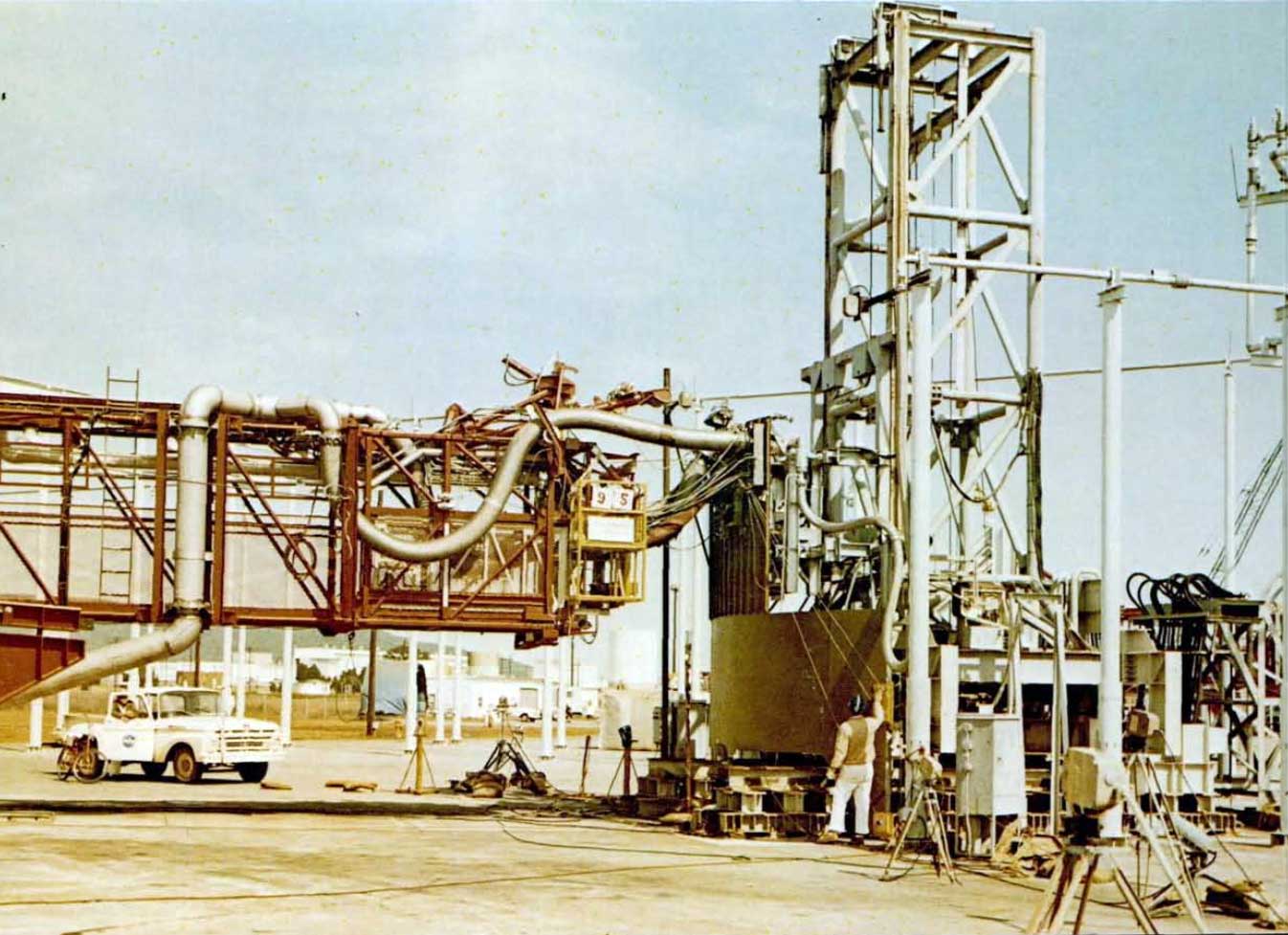

The connections between the ground and the towering space vehicle posed a tricky problem. An umbilical tower, even higher than the vehicle itself, was required to support an array of swingarms that at various levels would carry the cables and the pneumatic, fueling, and venting lines to the rocket stages and to the spacecraft. The swingarms had to be in place during final countdown, but in the last moments they had to be turned out of the way to permit the rocket to rise. There was always the possibility, however, of some trouble after the swingarms had been disconnected. For instance, the holddown mechanism would release the rocket only after all five engines of the first stage produced full power. lf this condition was not attained within a few seconds, all engines would shut down. In such a situation, unless special provisions were made for reattachment of some swingarms, Launch Control would be unable to “safe” the vehicle and remove the flight crew from its precarious perch atop a potential bomb.

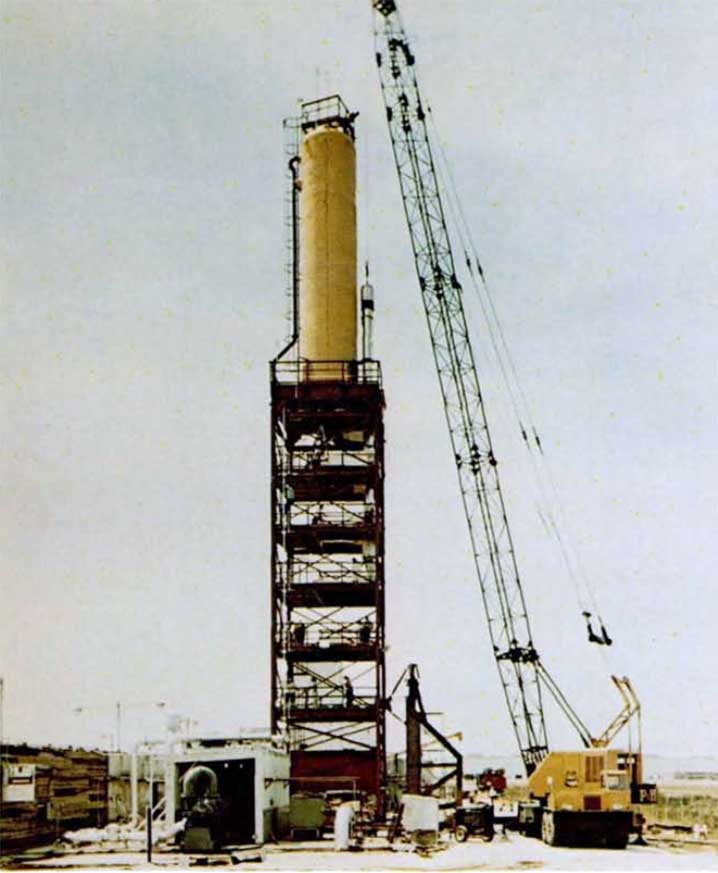

These considerations led to the establishment, at Marshall, of a special Swingarm Test Facility, where detachment and reconnection of various arms was tested under brutally realistic conditions. On the “Arm Farm” extreme conditions (such as a launch scrub during an approaching Florida thunderstorm) could be simulated. Artificial rain was blown by aircraft propellers against the swingarms and their interconnect plugs, while the vehicle portion was moved back and forth, left and right, simulating the swaying motions that the towering rocket would display during a storm.

Throughout Saturn V’s operational life, its developers felt a relentless pressure to increase its payload capability. At first, the continually growing weight of the LM (resulting mainly from additional operational features and redundancy) was the prime reason. Later, after the first successful lunar landing, the appetite for longer lunar stay times grew. Scientists wanted landing sites at higher lunar latitudes, and astronauts like tourists everywhere wanted a rental car at their destination. How well this growth demand was met is shown by a pair of numbers: The Saturn V that carried Apollo 8 to the Moon had a total payload above the IU of Iess than 80.000 pounds; in comparison, the Saturn that launched the last lunar mission, Apollo 17, had a payload of 116,000 pounds.