The Cape

By ROCCO A. PETRONE

At last everything was coming together - all those elements that had been committed piecemeal - the command module in Apollo 7, the first manned flight away from the bonds of Earth in Apollo 8, the flying of the lunar module with men on board in Apollo 9, and then Apollo 10, which went to the Moon and did everything short of landing. It all led up to that hot July morning in 1969, when Apollo’s moment of truth was irreversibly upon us.

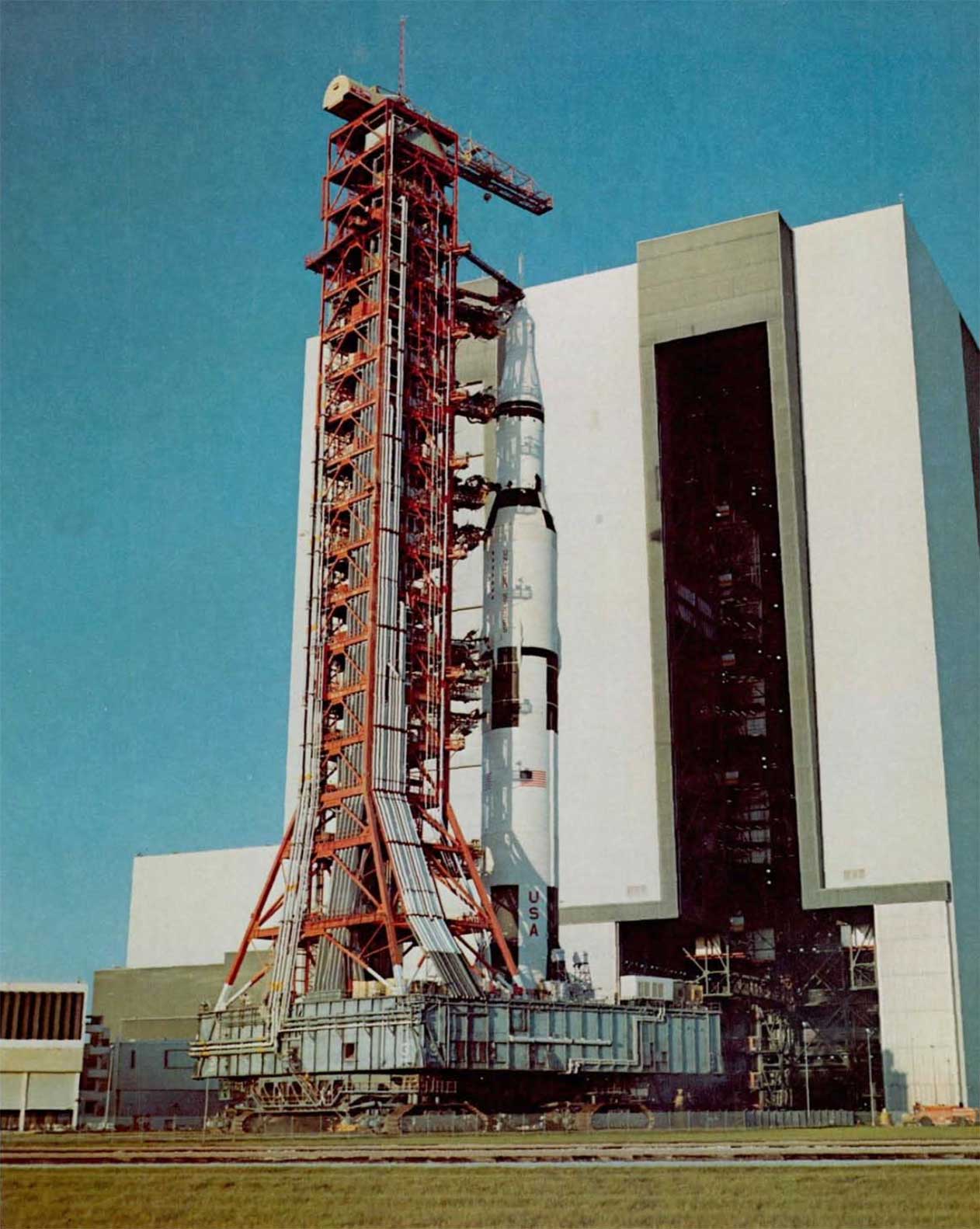

Uncounted things had to be done before we reached that moment. Before the operational phase even began, we had to pass through the conceptualization and construction phase, remembering something Jim Webb once said, “The road to the Moon will be paved by bricks and steel and concrete here on Earth.” For Apollo we had to build Complex 39 at a cost of half a billion dollars, that is, we had to finish Stage Zero, before we could proceed to Stage One, the flying of the birds.

Complex 39 was to Moon exploration what Palos was to Columbus: the takeoff point. Man had never attempted any such thing before, and I wonder when he will again. Everything was outsize - among the impressive statistics about the core of Complex 39, the Vehicle Assembly Building, were its capacity (nearly twice as big as the Pentagon) and its height (525 feet, thirty feet short of the Washington Monument’s).

During 39’s construction phase we were, of course, flying Saturn Is - ten of them - and in 1966 three Saturn IBs, all from Pads 34 and 37. Everything - launches and construction - had to mesh; it was like building a thousand different homes for a thousand demanding people. It was on the last of these IBs that I made my rookie appearance as director of launch operations, August 25, 1966. The mission was a 1 hour 23 minute suborbital flight to test the command and service module subsystems and the heatshield. CM 011 was recovered near Wake Island in good condition; its shield had withstood the heat of reentry at 19,900 mph.

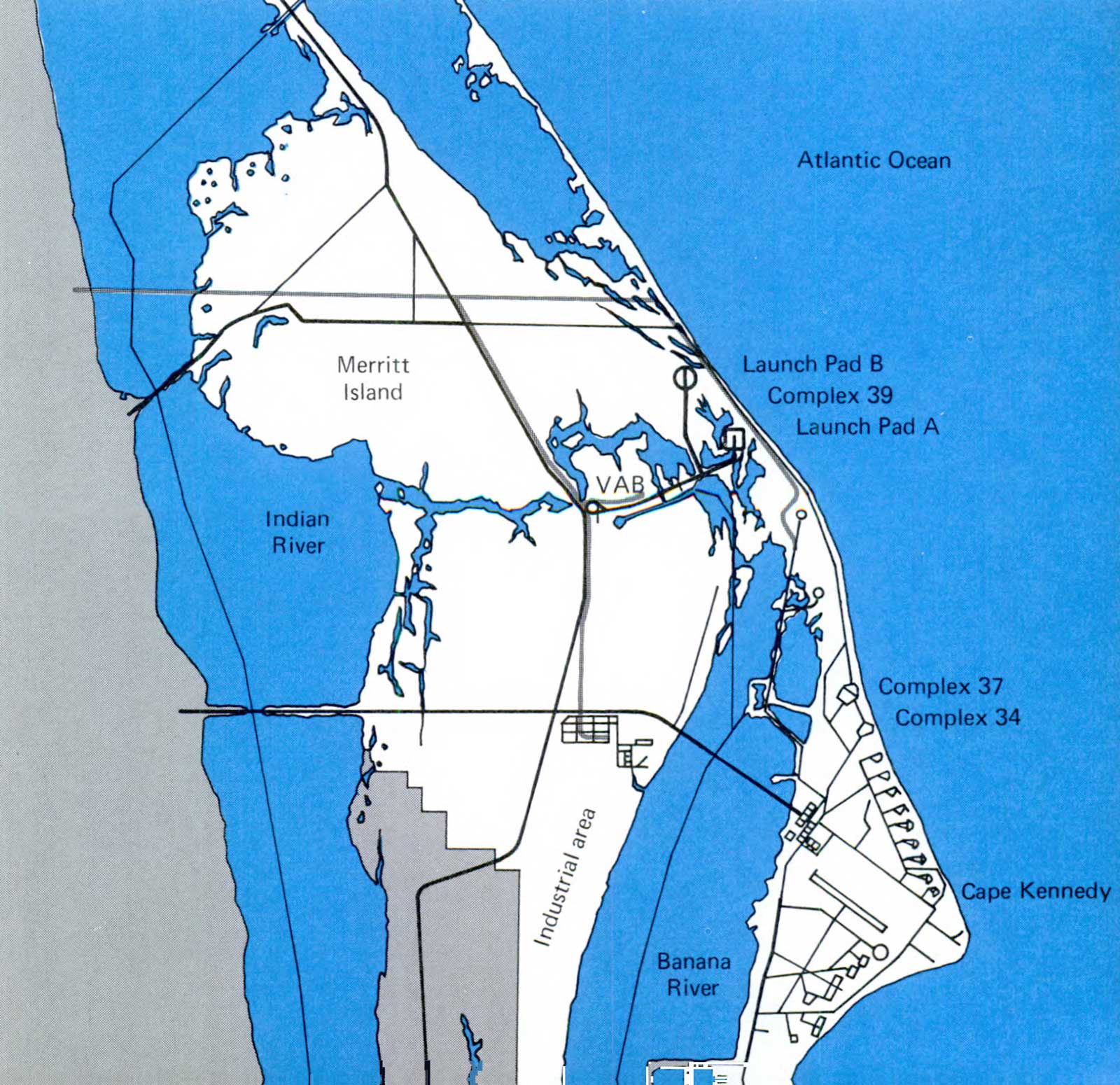

During the construction phase of Complex 39 (1961-66) I was Apollo Program Manager at the Cape. The first thing we had to do was decide where to build the moonport. My boss, Dr. Kurt Debus, and Maj. Gen. Leighton Davis, USAF, were directed to find a place from which to launch huge vehicles like the projected Nova or the Saturn V - Cape Canaveral’s 17,000 acres weren’t nearly large enough. In this study we considered sites in Hawaii, the California coast, Cumberland Island off Georgia, Mayaguana Island in the Bahamas, Padre Island off the coast of Texas, and several others. Eventually we concluded that the most advantageous site was Merritt Island, right next to the Air Force’s Cape Canaveral facilities, which had been launching missiles since 1950 and NASA vehicles since 1958. Our report was completed July 31, 1961, and we spent all night printing it, after which Dr. Debus and I flew up to Washington and briefed Mr. Webb and Dr. Seamans. So 84,000 acres of sand and scrub were acquired for NASA by the government, plus 56,000 additional acres of submerged lands, at a total cost of $71,872,000.

We lost no time in raising the curtain on Stage Zero. No one who was involved can ever forget the driving urgency that attended Apollo. Nor the dedication of those who worked on it, including the construction crews, who by 1965 numbered 7000 persons at the Cape.

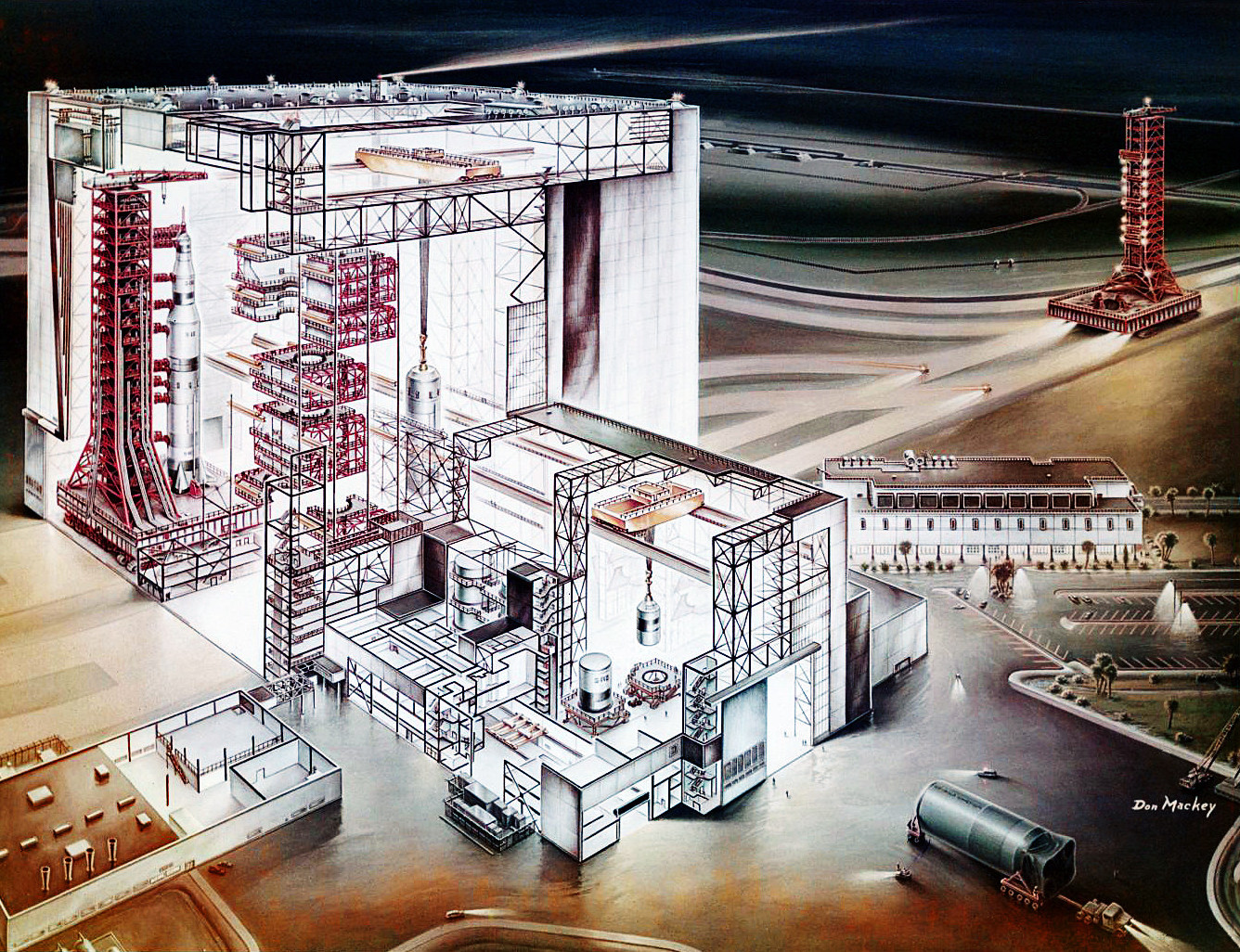

At one time we had considered preparing the space vehicle horizontally, and then erecting it vertically on the pad, but this was simply out of the question for a 360-foot bird. So we had to erect the Saturn V stage by stage, which meant that, because of rain and wind, we had to have an enclosed building. Even a 10- to 15-knot wind would have given us trouble while we were erecting outdoors, and higher winds could prove disastrous. Thus the Vehicle Assembly Building became an enclosed structure. Should the high bays be strung out four in a row, or built back-to-back? We decided on the latter format because only two big cranes (250-ton bridge cranes) would be needed instead of four, and because the box-like structure would better withstand hurricane winds of 125 mph. The possibility of hurricanes also dictated that we have two crawlers, one to carry the Mobile Service Structure away from the pad, and one to bring the Apollo-Saturn V and its Mobile Launcher to shelter in the VAB. The height of the building was dictated by the hook height, and we started planning for 465 feet; the final height was 525. Remember that when we started planning the VAB in 1961 we weren’t sure what size bird would roost in this big nest. We also had to begin design work before we knew whether the trip to the Moon would involve an Earth-orbit or lunar-orbit rendezvous.

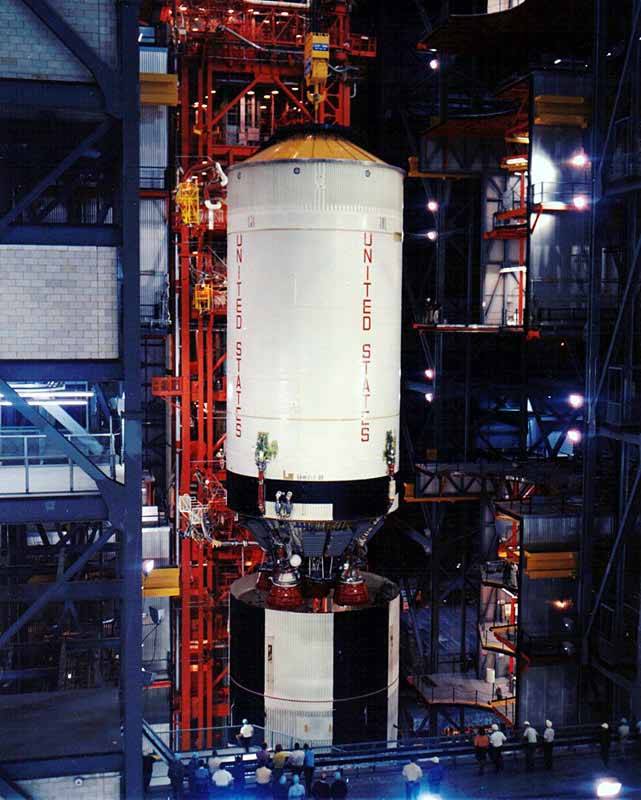

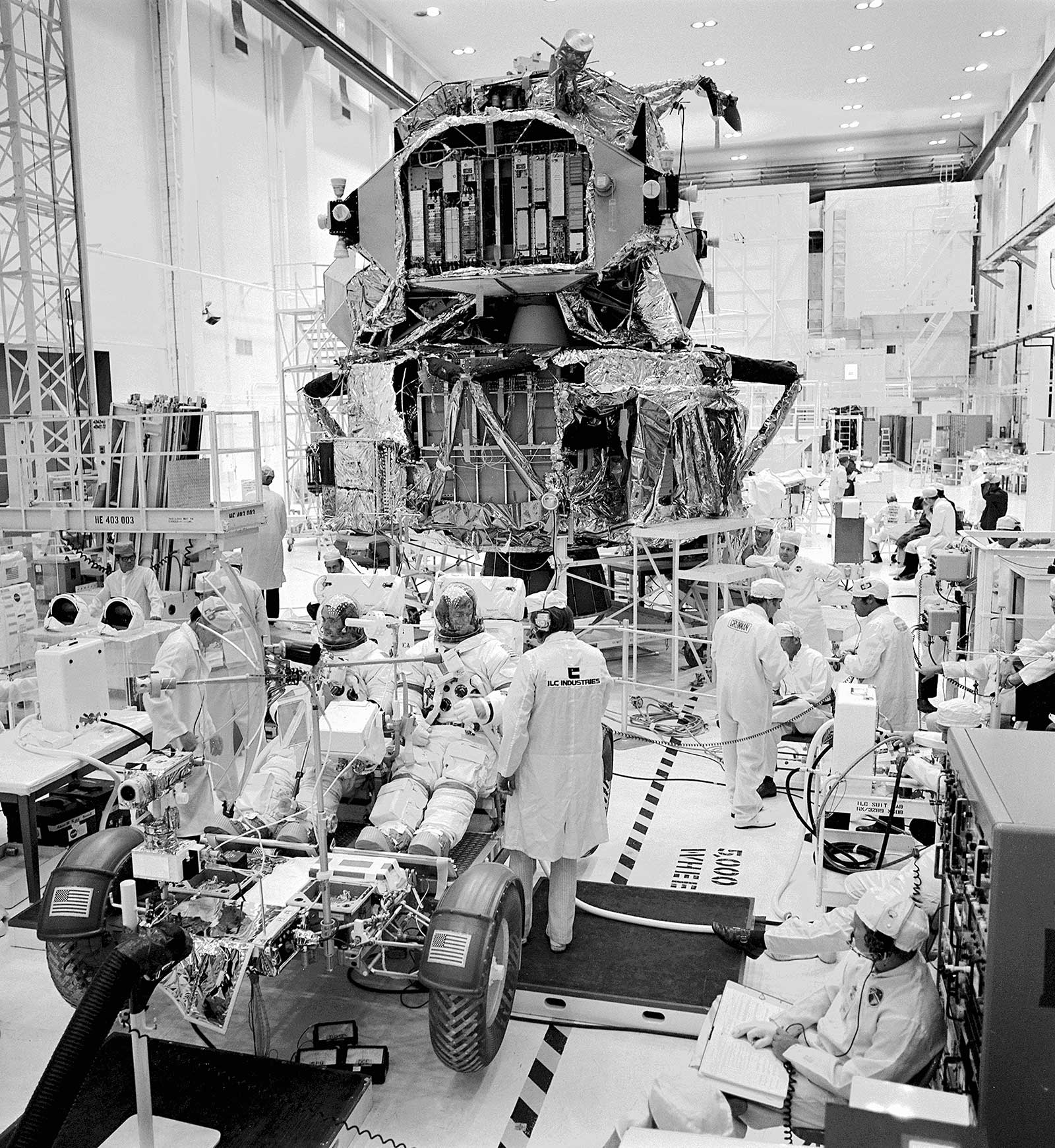

I think of the VAB not as a building but as an intricate machine that assembled the vehicle in its final phases. People were surprised to learn that the various stages had never seen each other until they were introduced in the VAB drydock. The first stage had been built by Boeing at Michoud outside New Orleans, the second stage by North American at Redondo Beach, Calif., the third by McDonnell Douglas at Huntington Beach, Calif., and the Instrument Unit by IBM at Huntsville, Ala. The spacecraft that went on top of this stack were also introduced for the first time in the VAB, the CSM from the North American plant at Downey, Calif., and the LM from Grumman in Bethpage, Long Island.

Could these pieces, arriving from all over the country, play together? Every wire in every plug had to join exactly the right wire, with no electrical interference or change of signal strength, and a command signal had to work from the Instrument Unit through the third and second stages into the first. After the various stages had been put together they had to be checked out as an entity, and once this had been done you naturally don’t want to break the electrical connections again. When the Instrument Unit orders “Go right”, you don’t want an engine three stages down to go left. The pieces not only had to match each other, but also the ground equipment. Lines for the flow of liquid hydrogen from the ground had to match the stages, and so did others for the flow of liquid oxygen and still others for gaseous nitrogen and helium. Television monitors had to be designed and installed so that we could know what was happening in hundreds of places at any given time - which meant all the time.

The skill required of the technicians working within Complex 39 - and throughout the Kennedy Space Center - had to be fine-honed. One of the legends had it that the crane operator who set the 88,000-pound second stage on top of the first stage had to qualify for the job by lowering a similar weight until it touched a raw egg without cracking the shell. Of the Cape’s 26,500 workers - the peak number in 1968 - a high percentage were men and women who possessed such skills. One can speculate whether such a crew is likely to be assembled in one place again.

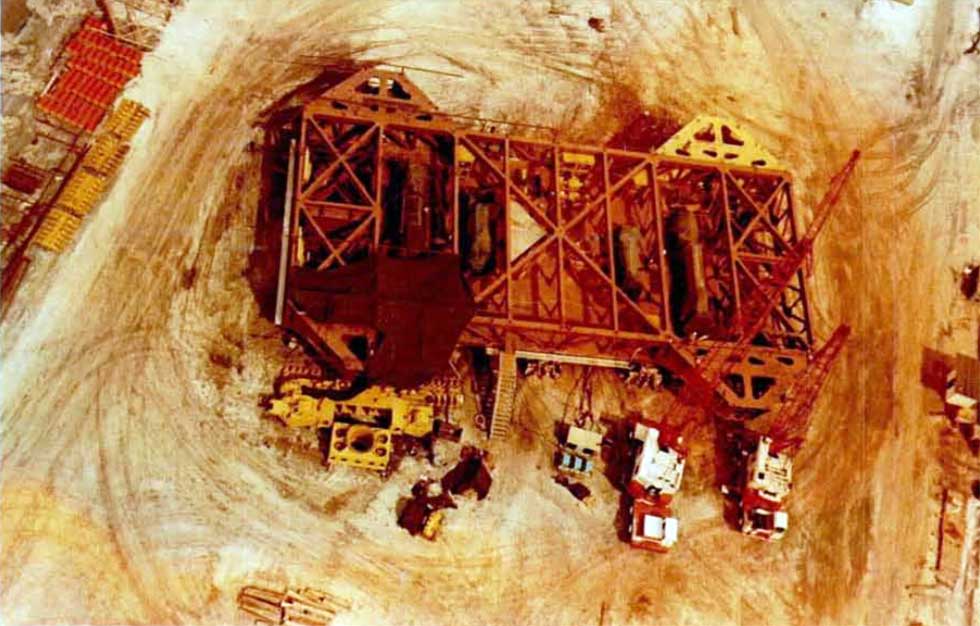

The pads of Complex 39 were abuilding at the same time the VAB rose on its 4225 16-inch steel pipe pilings that had been driven more than 160 feet below the sandy surface into bedrock. Pad A and Pad B were twins, each occupying about 160 acres; we had also planned a Pad C, which explains why the crawlerway from A to B has an elbow-like crook in it - the elbow would have led to C. (We even had a contingency plan for a Pad D in case launchings became more and more frequent.) The pads were built 8700 feet apart so that an explosion could not wreck more than one of them. They were located three and one-half miles from the VAB and the Launch Control Center. In the early days we’d had to control a launch from a site close to the pad, to avoid electrical problems induced by a longer run of electric cabling, which in turn meant that we worked from a blockhouse heavily protected against fire and blast. Now, by the time the Saturns were ready, digital data technology had advanced to the point where firing rooms could be in a structure miles away.

How to get the Apollo-Saturn V from its birthplace in the VAB to the pad from which it would fly for the first and only time in its life? Early in the program we considered moving it on its three and one-half mile journey by water. The barge concept was deep in our thinking: the first and second stages had to come to the Cape from Louisiana and California, respectively, by man’s oldest form of transportation, since they were too large to go through tunnels or under bridges. On this short trip why not also float the Saturn V and its Mobile Launcher standing upright on a barge? We got the Navy to run tests at the David Taylor Model Basin in Washington, which showed that the hydrodynamic requirements of such a topheavy barge would be too demanding. We looked into a rail system, into pneumatic-tire transporters, and ground effects machines but all were impractical or too expensive.

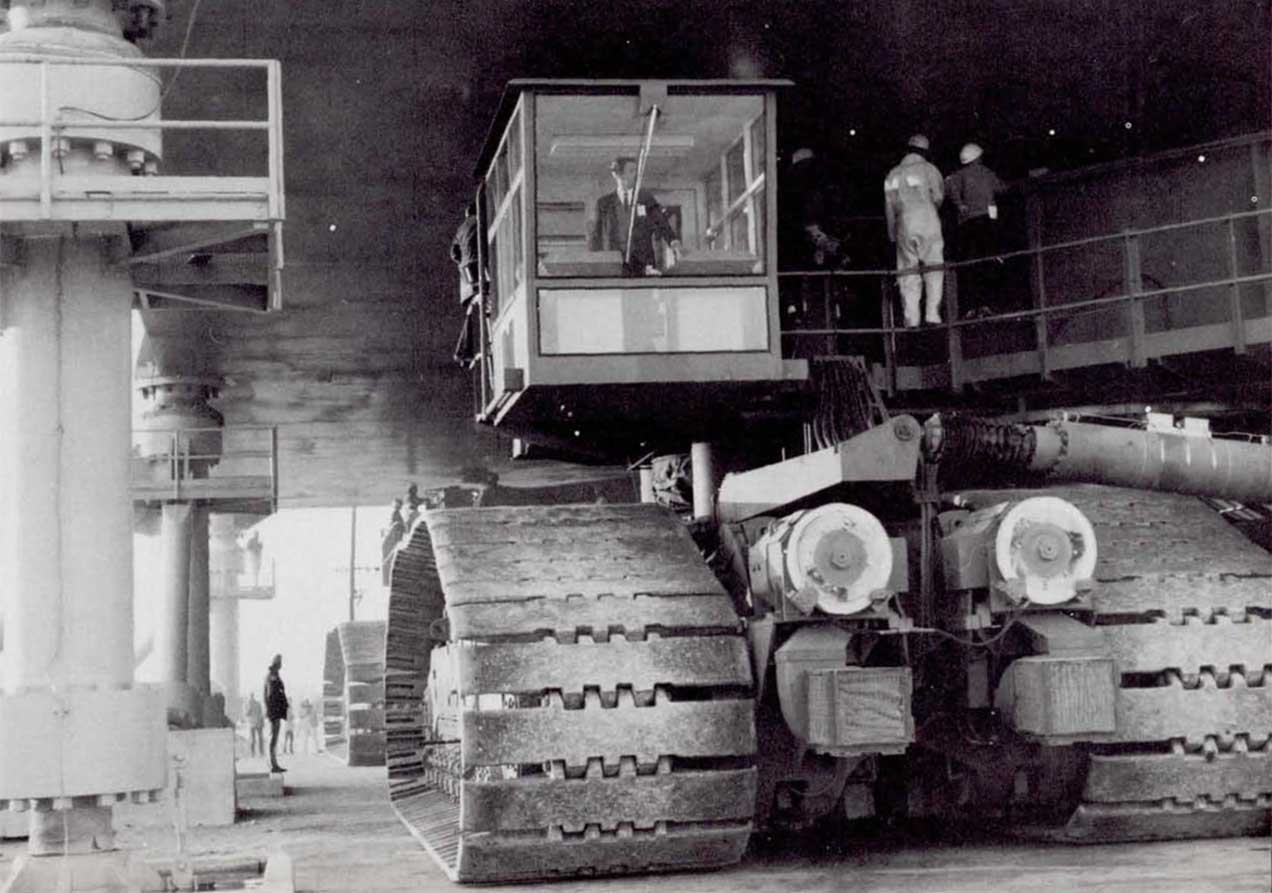

Then somebody in our shop came up with the idea of using giant tracked machines like those used in strip mining. What evolved was the unique crawler or, more politely, transporter. As built by the Marion Power Shovel Company, the crawler took shape with eight tracks, each 7 by 41 feet, with cleats like a Sherman tank, except that each cleat weighed a ton. Mounted over these eight tracks was the platform, bigger than a baseball diamond, on which the Apollo-Saturn V and its Mobile Launcher would ride majestically from VAB to pad at one mile per hour. The package weighed 9000 tons, two-thirds cargo, one-third crawler.

If that sounds easy, it wasn’t. In July 1965, during a test, some bearings cracked because we had assumed the weight would be equally distributed on various parts of the crawler. We were wrong. The bearings, incidentally, were ten inches in diameter and there were eleven sets of them. This problem was met by changing from roller bearings to sleeve bearings; we also topped off the crawlerway with eight inches of Alabama river rock to distribute the load evenly and to relieve friction at the turns.

KEEPING VERTICAL ON THE MOVE

The crawler also required a leveling system that would keep the Saturn V to within one degree of absolute vertical. The sensing system depended on two manometers - each 135 feet long, extending like an X from corner to corner under the platform; if they showed the deck was out of level by even half an inch, it was corrected by hydraulically raising or lowering one or more of the corners. Adjustments were made many times during the trip from the VAB, especially when the crawler climbed the five-degree incline leading up to the pad.

One of the great days in the history of the Cape was May 25, 1966, when Apollo-Saturn 500-F-a test vehicle built by Marshall Space Flight Center that duplicated everything except engines and spacecraft, of which it had none - rolled out of the VAB on the crawler and moved at glacial speed to Pad A, gleaming in the brilliant sunshine. It was the biggest rocket ever built by man, dummy though it was, and up there, safely on the pad, Saturn V was something to behold. It was five years to the day since President Kennedy had proposed landing a man on the Moon and returning him safely to Earth. When the crawler put the launcher on its supports that afternoon, one of the men who (along with me) breathed easier was Don Buchanan, on whose able shoulders the design responsibility for both the crawler and launcher had been placed three years before.

Dr. Debus had been wearing two hats, one as director of this growing Center, the other as director of launch operations. With the pressure mounting he decided to doff one of them, so two months after the roll-out of 500-F, I was appointed Director of Launch Operations, an assignment I held until after Armstrong, Aldrin, and Collins demonstrated in July 1969 that Apollo was a success.

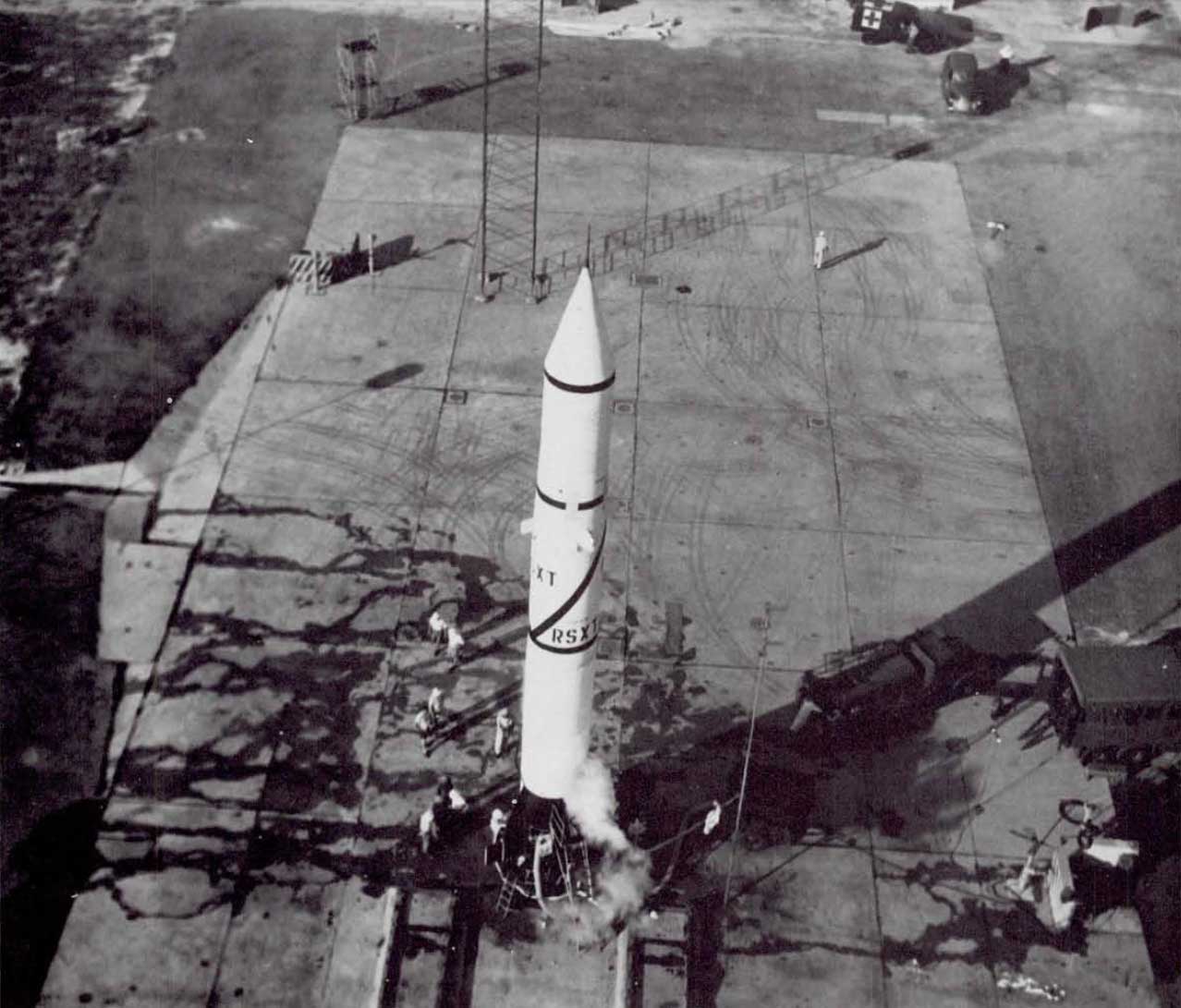

In the very early days there had been a lot of hit-and-miss, seat-of-the-pants business in launching rockets - and, insofar as the public was concerned, a lot of black magic. Some odd things happened. I recall a Redstone launch in May 1954, when I was still in the Army, that we had to delay because somebody reported a fishing skiff offshore, a dangerous place to be at liftoff time. We sent out some guards to warn the fishermen out of the way. By the time the guards reached the spot they found the boat was up on the beach and the fishermen were gone. Then we had to send someone to find the guards and tell them to come back, and that took another hour before we could launch. At other times the count would be held up because diesel engines powering a tractor didn’t work, or a key to the tractor had been lost.

But we learned as we traveled this long road. The really big event was the launch of the first Saturn V, November 9, 1967, which we designated Apollo 4. To me that was the real mark; its success meant we were really going to make the Moon landing. To bring together the massive hardware and the complex ground equipment exactly when we wanted to was an achievement. You don’t look at a thing like the Saturn V without a lot of humility in your heart. Consider the three stages, the Instrument Unit, the vast amount of automation, the many computers on the ground and in the stack, the swing arms, the hold-down arms, the propellant loading system - all these were intricate and potentially troublesome elements that had to be brought up to speed, and at a vast launch complex that was being used for the first time.

We kept having problems during the Countdown Demonstration Test in September and October; it was scheduled for three and one-half days, but lasted 23. We’d go so far, and we’d find a leak. We had ground equipment problems, then procedural problems; batteries failed, and pressure gauges developed faults. But these problems melded our team, as in a cauldron. Under pressure our people came of age, in the firing room and on the pad. When the five engines of Saturn 501 fired up at 7 a.m. we had confidence, which proved to be justified.

By the time of Apollo 11, the number of printed pages, including interface control documents, that were required to check out a space vehicle actually surpassed 30,000. We had to make so many copies that a boxcar would have been required to hold the documents necessary to launch a Saturn V. The more contractors involved, the greater the need for formality. No more holding up launches for fishing skiffs; no more offhand decisions such as we sometimes had to make in the early days. The schedule was always upon us in Apollo. We had to work concurrently on different launch flows. When Apollo was at its peak we had three firing rooms working simultaneously in the launch control center, with three crews of 500 apiece manning the consoles. That took a lot of manpower, and the person I depended on most heavily to keep the operation moving was Paul Donnelly, an unflappable veteran of Mercury and Gemini days.

A LAUNCH EVERY OTHER MONTH

The centers - that’s what we called intervals - between launches were two months. That is, Apollo 9 went in March, Apollo 10 in May, and Apollo 11 in July. But each vehicle took five months from the time its components arrived in the VAB until its launch. Thus the overlapping.

Look at the situation in early March 1969. Apollo 9 on Pad A was ready for launch - delayed three days because the astronauts caught colds - and the team of 500 - engineers and technicians - was working twelve- or thirteen-hour days. Apollo 10 was ready to be rolled out of the 456-foot hangar doors of the VAB for two months of intensive checkout on Pad B. But the components of Apollo 11 had already arrived and were undergoing tests in the VAB and in the vacuum chambers of the Manned Spacecraft Operations Building. Apollo 11 would roll out at 12:30 p.m., May 20, one month and 26 days before it lifted off for the Moon.

The pressure on these people was pretty severe. At a launch a person just sat there glued to his console, watching the needles for any sudden changes, knowing that he would be committing this big vehicle, with men aboard: a $400 million commitment. And it wasn’t the money only, or the men. The entire world was watching for the success of the United States.

We had both to prepare the bird and to make sure our people could detect and understand any anomaly. I used to walk through the console panel area right up to about the last 45 minutes before liftoff. I’d be checking on alertness, especially among men who had been working long hours. Were they fatigued? Were they concentrating on the dials? Was there any unnecessary chit-chat going on? When we had long holds during the Countdown Demonstration Tests I had to judge how far we could go, whether we were pushing too hard, whether we had to call a delay and wait until the next day. The team had to be as well rehearsed as any ballet, or any football team. You do not get the commitment for launch without a lot of hard days and weeks and months of practice.

TESTING THE TEAM

About eighty percent of the people on these teams worked for the contractors; the rest were NASA employees. All of them had to go through examinations. We’d call a man in - say a swing-arm console operator - before a board of three or four examiners and we’d have his part of the mission simulated on a console. He would have five minutes to get set, before making split-second decisions. We’d say, “Okay, here’s your console, and here’s your condition.” The examiners would move a red-green slide, or put a yellow light on. The operator would look at the simulation on his console, and say, “Okay, that’s green, and it means the pressure is okay; that’s red and it means the pressure is too low.” Dozens of other simulators would test his proficiency. We had to make sure. We had to be able to say “We understand the problems, we’ve done the detective work; we’ve found the solution and we’ve tested it, and we have confidence everything will work”.

In our testing we had a building block approach, very logical, very methodical; you built each test on the last test, and the whole sequence expanded in the process. Everything culminated in the two main tests, Flight Readiness and Countdown Demonstration. Flight Readiness would take us through the total flight, including an abbreviated trip to the Moon, with all the valves working, all the sequences following according to the logic we had worked out for them. It was a total test of the electrical system and the software.

The Flight Readiness Test was dry (that is, without propellants) but the Countdown Demonstration Test (93 hours) was loaded with propellants, including several thousand tons of cryogenics in the three stages and tons of RP-1 fuel in the first stage. This one we took right up to the point of 14 seconds before ignition. We had four or five different ways to stop the countdown sequence at 14 seconds, and I would customarily look at Ike Rigell and say “How many stops have we got?”. The test had to be stopped at T minus 14 seconds because if it went down to 9 we would activate the ignition sequence. So everybody wore a sort of tense smile when it came to 14 seconds. We never had an accidental ignition, which would have meant chaos. (We did not have the astronauts in the CM during this part of the CDDT.)

Then we would unload the cryogenic propellants and dry out the tanks, which took five or six hours, a little longer than it took to load. Next day we would pick up the count at about three hours and run through the schedule up to simulated lift-off, now with the astronauts on board. It was important for the flight crew to go through this final exercise: to suit up in the Manned Spacecraft Operations Building, get in the vans, ride out to the pad, load into the CM, and check the flight systems.

I have often been asked why it took hundreds of men to launch the astronauts to the Moon, whereas just two of them on the Moon can launch themselves back to Moon orbit. Well, the two of them were there on the Moon in the LM’s ascent stage. They had everything they needed: their fuel was loaded; they had water; their cooling system was working and so was their oxygen supply. Their radar was tracking and their communications to Earth were functioning, and long before launch we had checked to see that they had no electrical interference. These systems were working because of the preparations and check-out efforts of hundreds of people on the ground before the spacecraft was committed to launch.

WHEN THE RED LIGHT LIT UP

It was remarkable that every manned Apollo launch lifted off exactly on schedule, up to the last one. (Apollo 14’s forty-minute delay was due to weather.) But Apollo 17, the only night launch, was delayed 2 hours and 40 minutes, until 12:33 a.m., because of the failure of an automatic countdown sequencer in the ground equipment. The way we had the launch set up was that the last three-minute period in effect was a series of automatic commands, all done by a timer. If you didn’t get through a certain gate in the automatic sequencer the next command would not be given. This protected us against a faulty liftoff.

This is what the term “terminal sequence” meant, which took a great deal of check-out time in the months preceding launch. When we got down to 30 seconds before lift-off, the indication of pressurization for one of the propellants in the S-IVB stage hadn’t registered, so the sequencer stopped the count. The red light on the overhead indicator in the firing room lit up. The engineer monitoring that read-out on the strip chart told us the S-IVB was not pressurized. The ladder in the sequence wasn’t met, so we got a cut-off at 30 seconds.

The team went through a back-out act, as they had practiced, the arming command was withdrawn, the on-board batteries were taken off line, the radio-frequency transmitters turned off, and within three or four minutes the space vehicle had been returned to a status where we could safely hold. Everything was done very coolly, very gingerly. Gene Cernan, the commander of the flight, said later that he kept his hand - very tightly - on the abort switch, “because you never know”. But once again the launch escape tower went unused.

The problem turned out to be a faulty diode in the terminal sequencer. Among the hundreds of commands given in sequence, one was not forthcoming, so everything stopped - which is one of the marvels of Apollo. At this late date in the program nobody batted an eye, including Walter J. Kapryan, the able engineer who had succeeded me as launch director when I went to Washington as Apollo Program Director three years earlier.

No story about the Cape - Canaveral, then Kennedy, then Canaveral again - would be complete without a mention of the visitors. By the time the Apollo program ended in 1972 we had attracted more than 6 million of them, and that doesn’t count people who lined the roads and watched the lift-offs (there were a million of those, it was estimated, for Apollo 11). We had VIP visitors in a steady stream - Presidents of the United States, members of the Supreme Court, members of Congress, almost any prominent person you could mention.

We had leaders from many countries - I recall the Shah of Iran, King Hussein of Jordan (he was a jet pilot), the King of Afghanistan, King Baudoin of Belgium, Haile Selassie of Ethiopia, Chancellor Erhard of Germany, and President Radhakrishnan of India, who had been a professor of philosophy at Oxford. Other visitors included foreign ministers and cabinet members from many countries. We talked to most of them in informal sessions, explaining as best we could the mysteries of spaceflight. The one visitor who impressed me most came in November 1963, and we briefed him on a Saturn-Apollo unmanned mission due to fly in January - which would be the first Saturn I to carry two stages (with a total of 14 engines, still the record for launch vehicles). He promised to come back for the launch if he possibly could. But he never made it because he was assassinated in Dallas six days later.